Experience accurate magnetic field detection across three axes, ideal for motion-critical applications like robotics and HMI

A

A

Hardware Overview

How does it work?

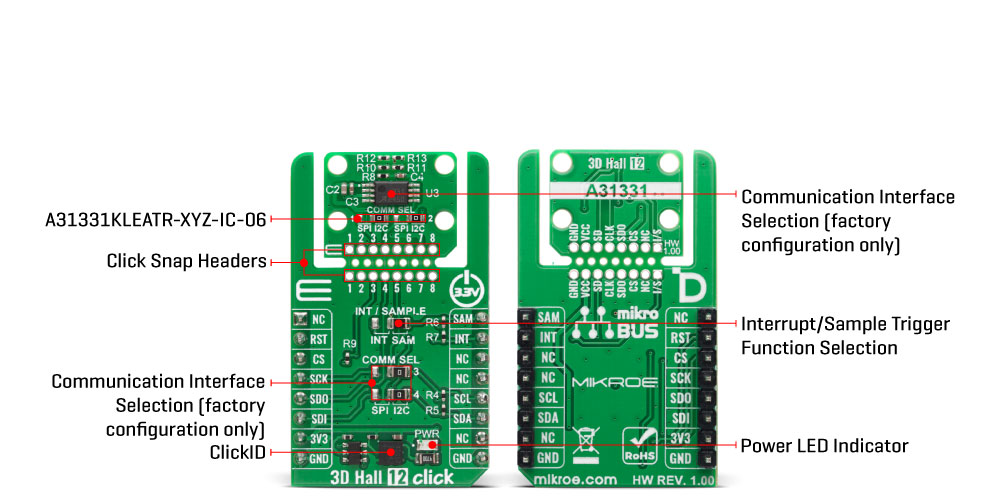

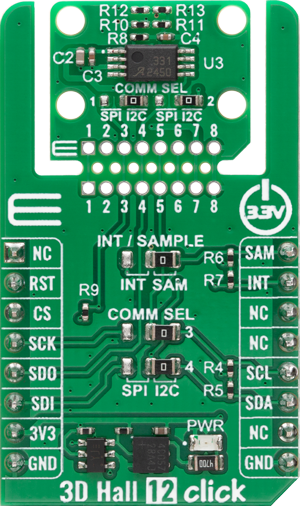

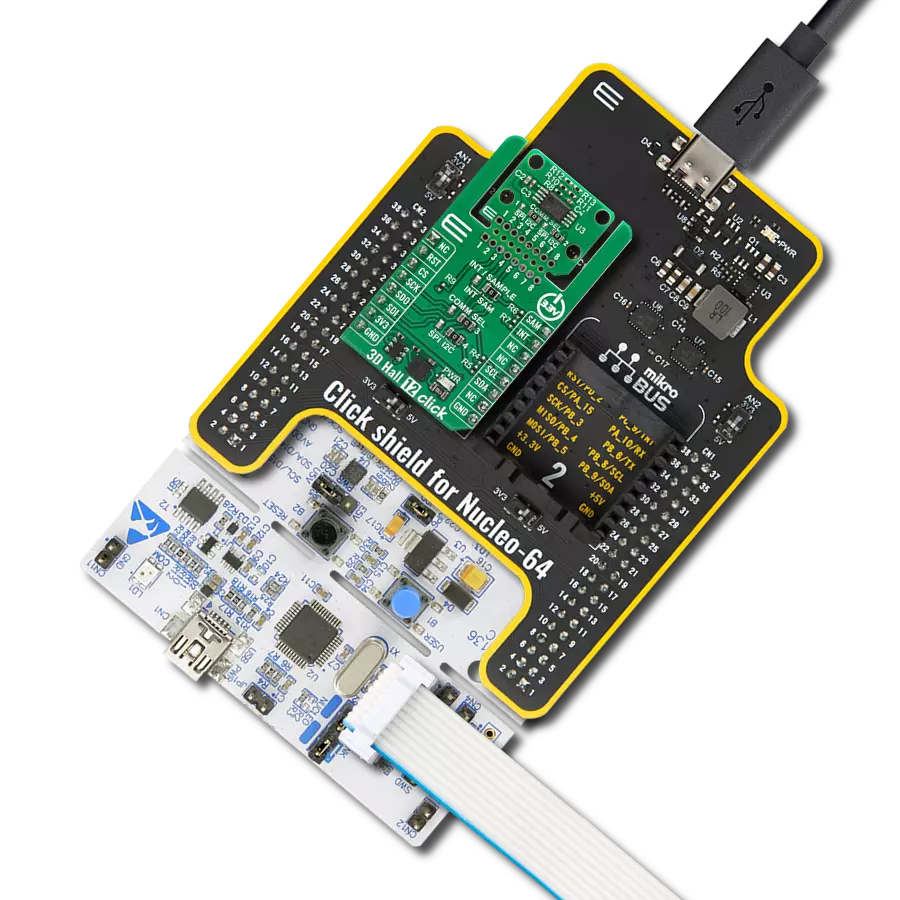

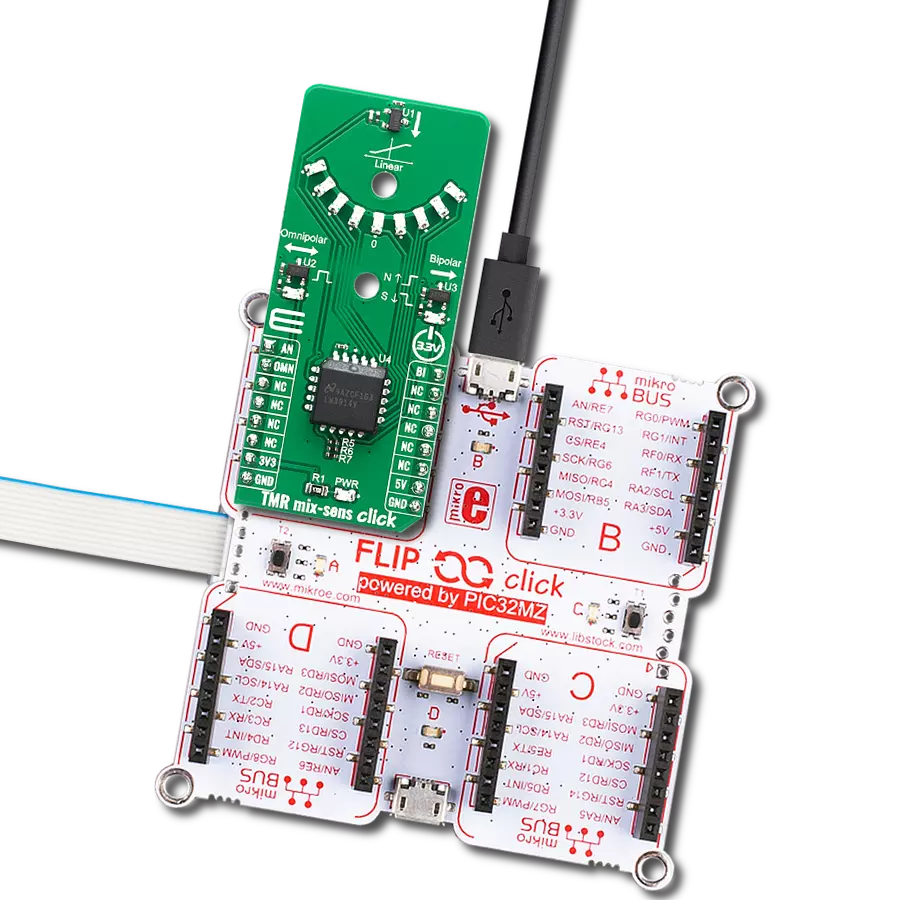

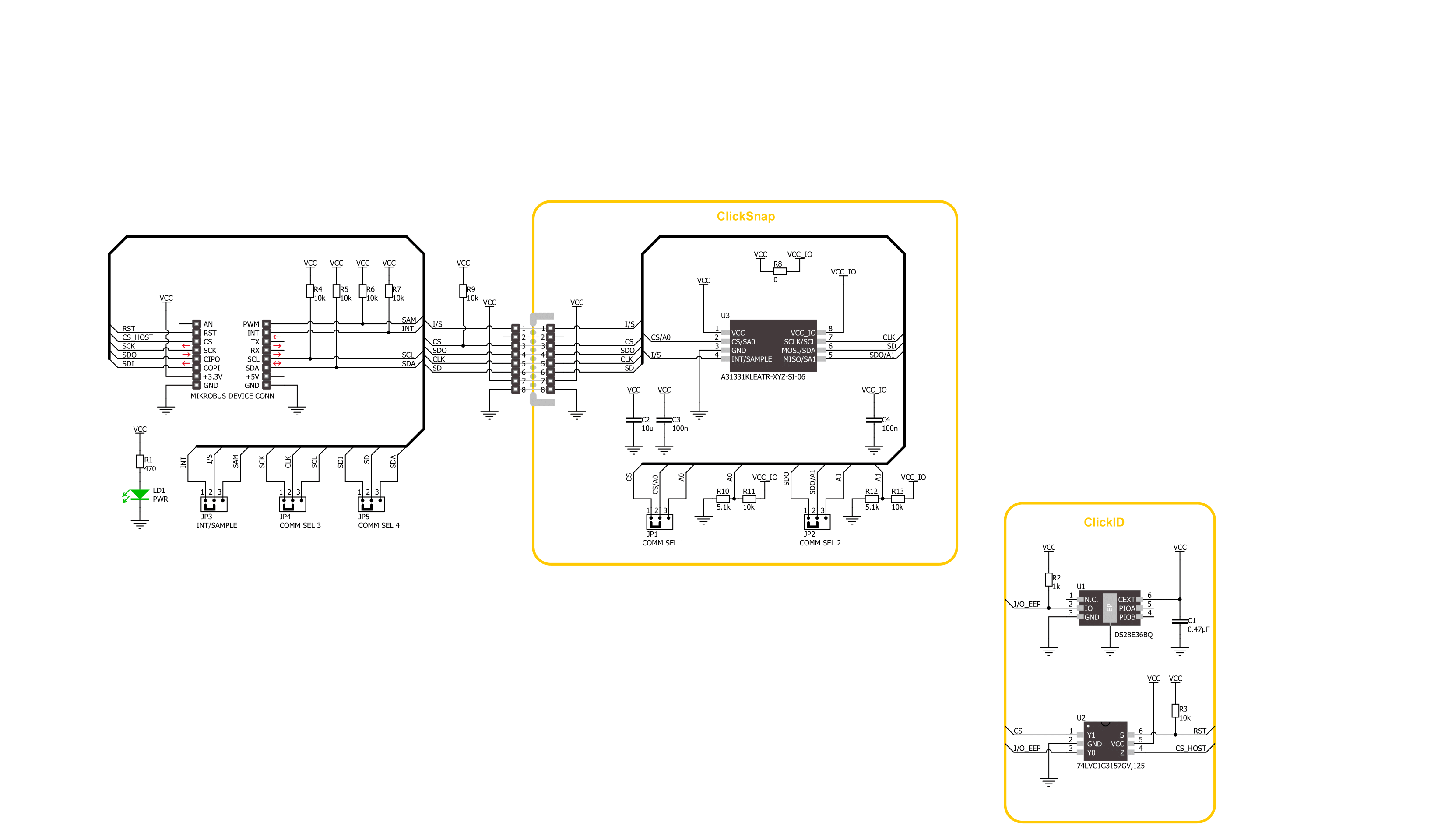

3D Hall 12 Click - I2C is based on the A31331KLEATR-XYZ-IC-06, an AEC-Q100 Grade 1 automotive-qualified 3D linear Hall-effect sensor IC from Allegro Microsystems, that provides highly precise magnetic field measurements in three dimensions for a variety of embedded applications. It offers advanced low-power management and flexible magnetic sensing capabilities. This A31331 IC is capable of measuring applied flux density across any one, two, or all three axes simultaneously, while also supporting angle calculation in up to any two user-defined planes, making it highly versatile for complex magnetic sensing tasks. It features a standard magnetic field range of ±600G combined with a sensitivity of 24.82LSB/G, enabling precise detection of magnetic field variations. Communication of the A31331KLEATR-XYZ-IC-06 with the host MCU is achieved via an I2C interface that supports operation up to 1MHz, and the device's I2C address is programmable via EEPROM, allowing up to 127 unique addresses for multi-device configurations on the same I2C bus. Additionally, the A31331 includes a customer-programmable magnetic temperature coefficient with factory default trimming, ensuring stable performance across different magnets, air gaps, and varying temperatures. The power management system of the A31331 is highly configurable, providing

system-level flexibility to balance supply current consumption with sensor performance as needed. Its low-leakage sleep current mode makes it particularly well-suited for battery-powered and portable designs, including thermal and smart valve control, industrial motion control, human-machine interfaces, and general-purpose actuator applications. This Click board™ is designed in a unique format supporting the newly introduced MIKROE feature called "Click Snap." Unlike the standardized version of Click boards, this feature allows the main sensor/IC/module area to become movable by breaking the PCB, opening up many new possibilities for implementation. Thanks to the Snap feature, the A31331KLEATR-XYZ-IC-06 can operate autonomously by accessing its signals directly on the pins marked 1-8. Additionally, the Snap part includes a specified and fixed screw hole position, enabling users to secure the Snap board in their desired location. In addition to supporting the A31331KLEATR-XYZ-IC-06 variant, the 3D Hall 12 Click has been designed with a flexible footprint that accommodates other versions of the A31331 sensor family as well, like one that uses the SPI communication interface. The SPI-compatible variants offer high-speed communication capabilities, operating at clock frequencies up to 10MHz, providing an alternative for applications that require faster data transfer or prefer the

deterministic nature of SPI over I2C. To support both communication protocols, the Click incorporates a set of COMM SEL jumpers that allow the user to select the desired interface by configuring all jumpers accordingly. It is important to emphasize that all COMM SEL jumpers must be set to the same position to ensure proper operation of the Click board, as mixed jumper settings may lead to communication errors or malfunction. In addition to the primary communication pins, the 3D Hall 12 Click - I2C also uses two auxiliary pins labeled SAM and INT, which are dedicated to the sensor’s sample trigger and interrupt functions. Since both of these signals are multiplexed on a single multifunctional pin of the A31331 sensor, the board integrates an INT / SAMPLE jumper to conveniently select the desired operational mode. By setting this jumper accordingly, the user can easily configure the sensor’s pin behavior, either to output an interrupt signal or to serve as an external sample trigger input, depending on the application requirements. This Click board™ can be operated only with a 3.3V logic voltage level. The board must perform appropriate logic voltage level conversion before using MCUs with different logic levels. It also comes equipped with a library containing functions and example code that can be used as a reference for further development.

Features overview

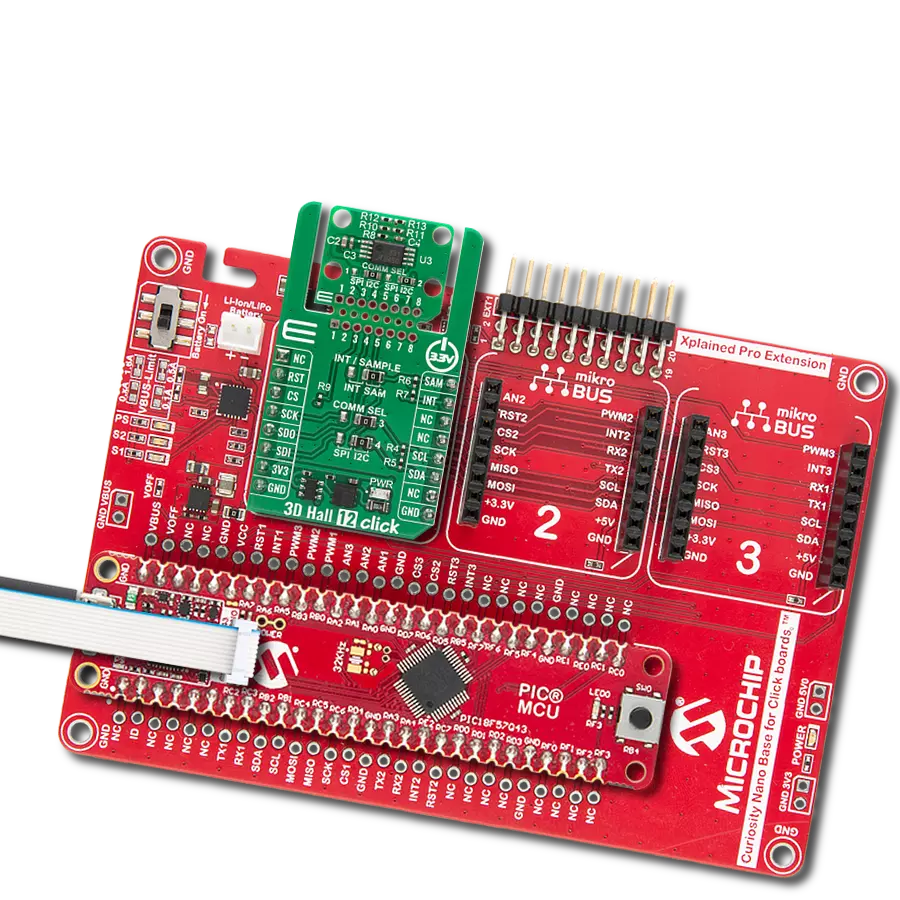

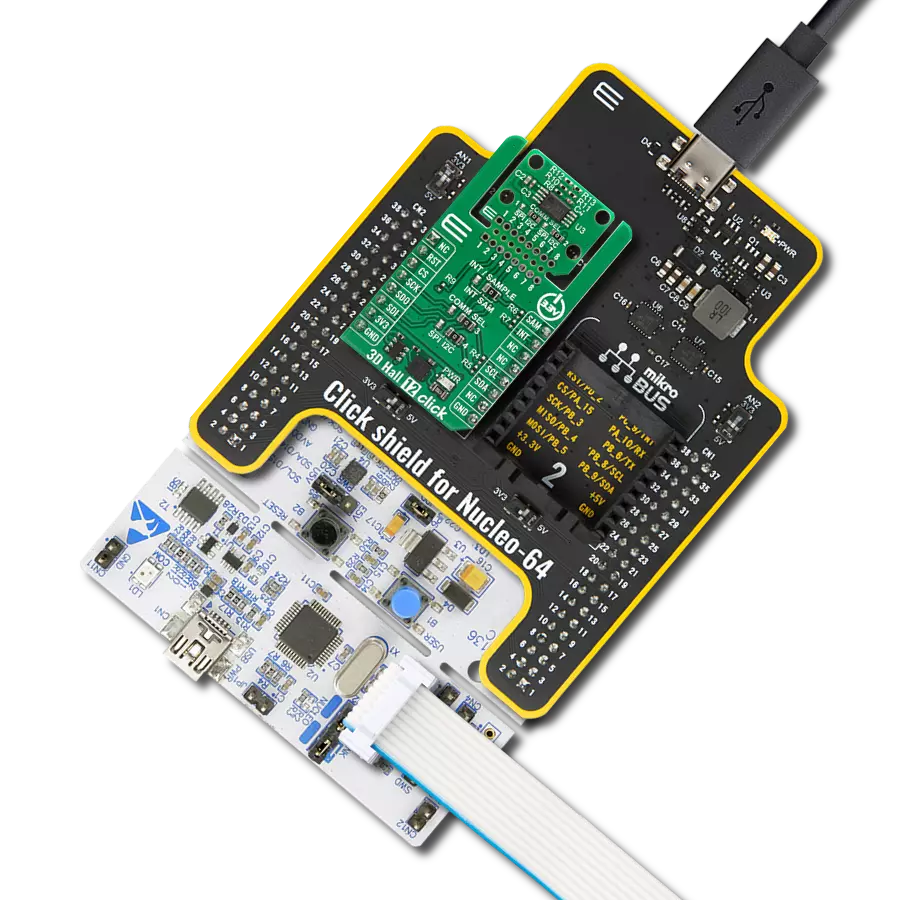

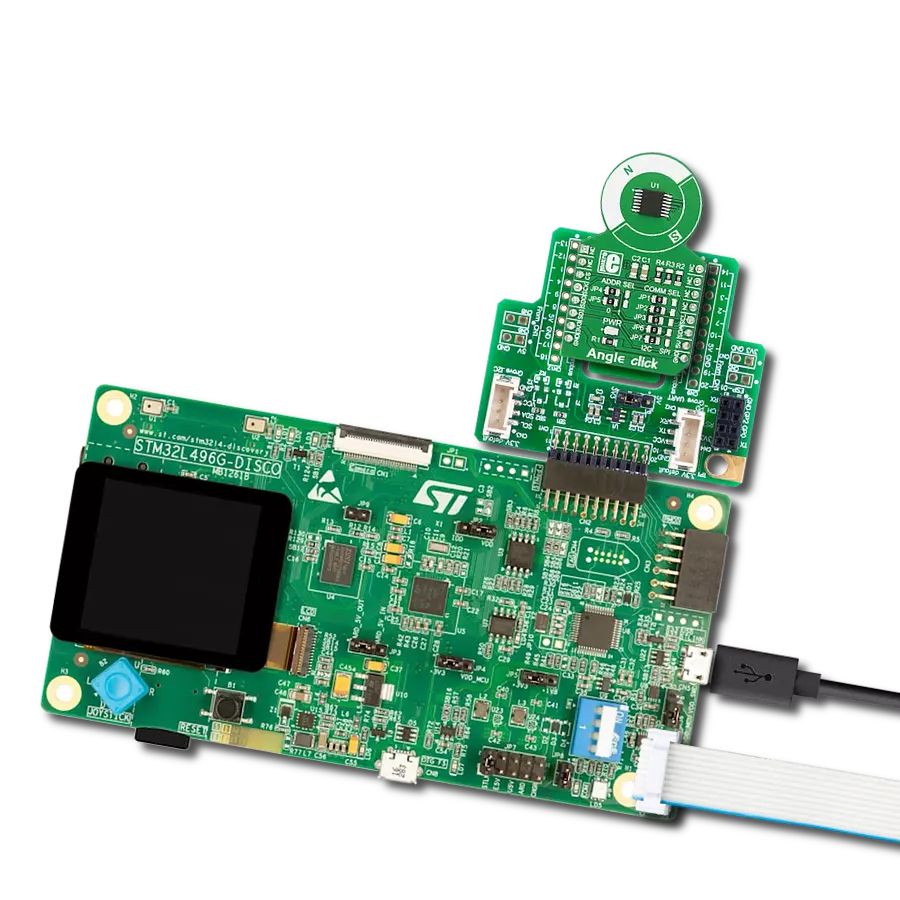

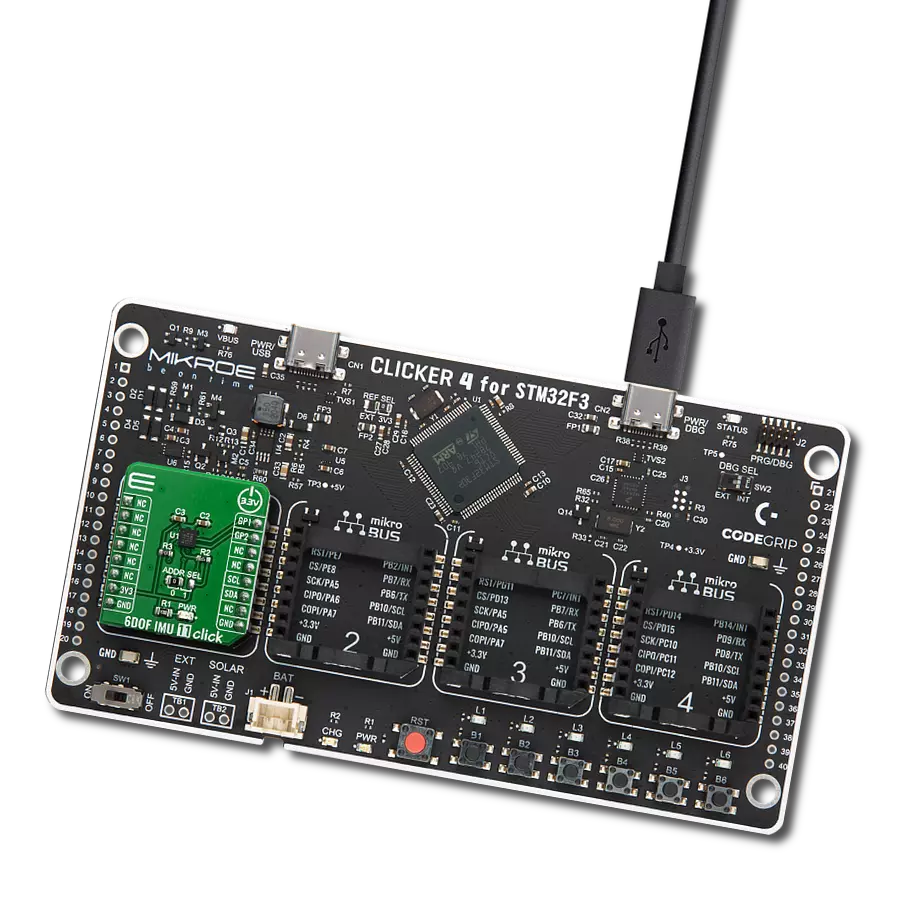

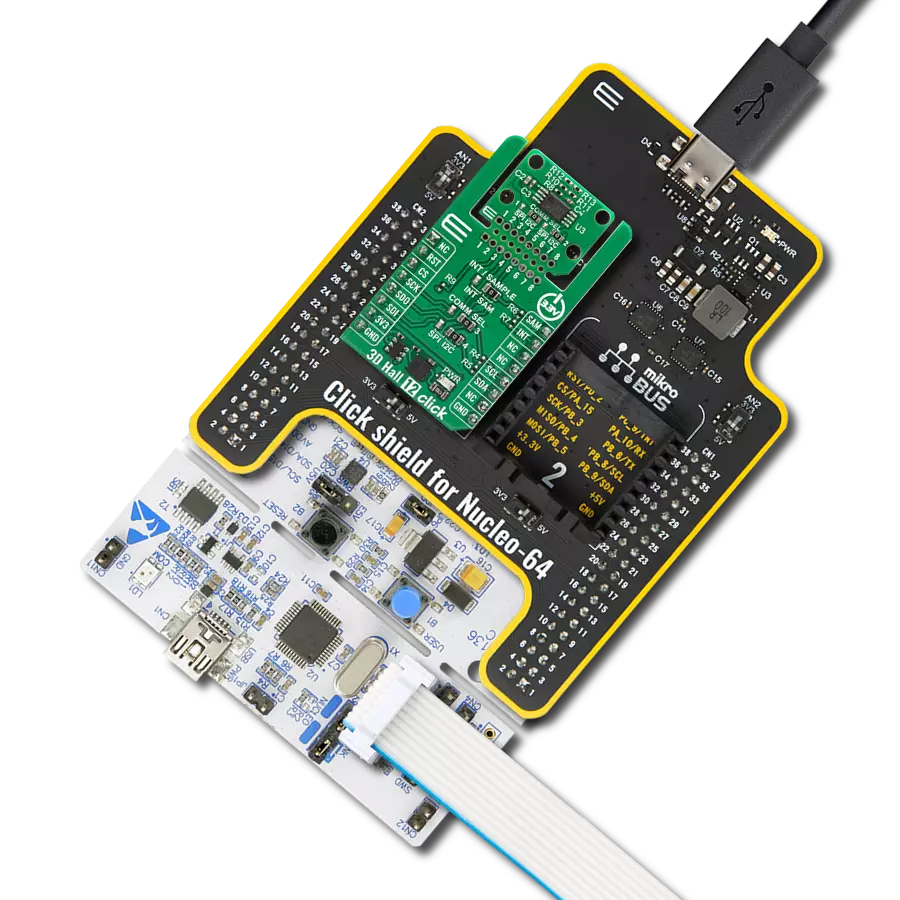

Development board

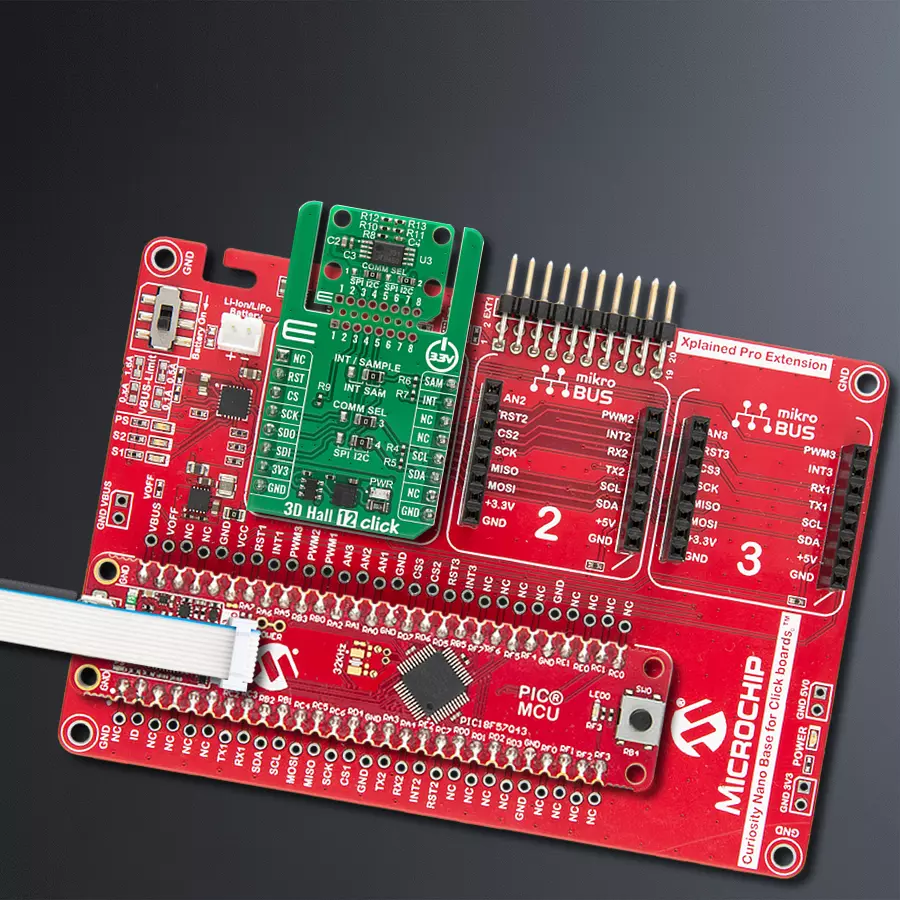

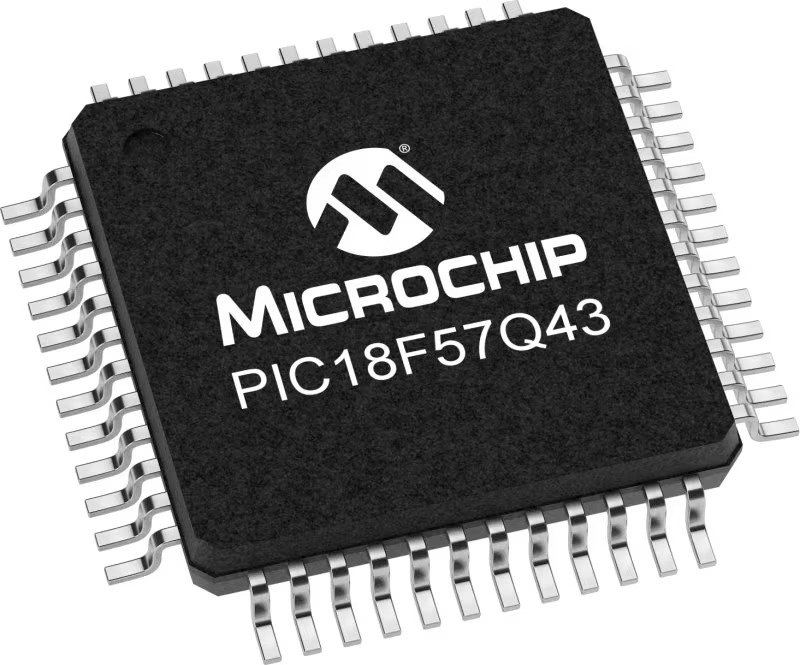

PIC18F57Q43 Curiosity Nano evaluation kit is a cutting-edge hardware platform designed to evaluate microcontrollers within the PIC18-Q43 family. Central to its design is the inclusion of the powerful PIC18F57Q43 microcontroller (MCU), offering advanced functionalities and robust performance. Key features of this evaluation kit include a yellow user LED and a responsive

mechanical user switch, providing seamless interaction and testing. The provision for a 32.768kHz crystal footprint ensures precision timing capabilities. With an onboard debugger boasting a green power and status LED, programming and debugging become intuitive and efficient. Further enhancing its utility is the Virtual serial port (CDC) and a debug GPIO channel (DGI

GPIO), offering extensive connectivity options. Powered via USB, this kit boasts an adjustable target voltage feature facilitated by the MIC5353 LDO regulator, ensuring stable operation with an output voltage ranging from 1.8V to 5.1V, with a maximum output current of 500mA, subject to ambient temperature and voltage constraints.

Microcontroller Overview

MCU Card / MCU

Architecture

PIC

MCU Memory (KB)

128

Silicon Vendor

Microchip

Pin count

48

RAM (Bytes)

8196

You complete me!

Accessories

Curiosity Nano Base for Click boards is a versatile hardware extension platform created to streamline the integration between Curiosity Nano kits and extension boards, tailored explicitly for the mikroBUS™-standardized Click boards and Xplained Pro extension boards. This innovative base board (shield) offers seamless connectivity and expansion possibilities, simplifying experimentation and development. Key features include USB power compatibility from the Curiosity Nano kit, alongside an alternative external power input option for enhanced flexibility. The onboard Li-Ion/LiPo charger and management circuit ensure smooth operation for battery-powered applications, simplifying usage and management. Moreover, the base incorporates a fixed 3.3V PSU dedicated to target and mikroBUS™ power rails, alongside a fixed 5.0V boost converter catering to 5V power rails of mikroBUS™ sockets, providing stable power delivery for various connected devices.

Used MCU Pins

mikroBUS™ mapper

Take a closer look

Click board™ Schematic

Step by step

Project assembly

Track your results in real time

Application Output

1. Application Output - In Debug mode, the 'Application Output' window enables real-time data monitoring, offering direct insight into execution results. Ensure proper data display by configuring the environment correctly using the provided tutorial.

2. UART Terminal - Use the UART Terminal to monitor data transmission via a USB to UART converter, allowing direct communication between the Click board™ and your development system. Configure the baud rate and other serial settings according to your project's requirements to ensure proper functionality. For step-by-step setup instructions, refer to the provided tutorial.

3. Plot Output - The Plot feature offers a powerful way to visualize real-time sensor data, enabling trend analysis, debugging, and comparison of multiple data points. To set it up correctly, follow the provided tutorial, which includes a step-by-step example of using the Plot feature to display Click board™ readings. To use the Plot feature in your code, use the function: plot(*insert_graph_name*, variable_name);. This is a general format, and it is up to the user to replace 'insert_graph_name' with the actual graph name and 'variable_name' with the parameter to be displayed.

Software Support

Library Description

3D Hall 12 Click - I2C demo application is developed using the NECTO Studio, ensuring compatibility with mikroSDK's open-source libraries and tools. Designed for plug-and-play implementation and testing, the demo is fully compatible with all development, starter, and mikromedia boards featuring a mikroBUS™ socket.

Example Description

This example demonstrates the use of 3D Hall 12 Click - I2C by reading the magnetic flux density from 3 axes, and the angle and magnitude between X and Y axes as well as the sensor internal temperature.

Key functions:

c3dhall12i2c_cfg_setup- This function initializes Click configuration structure to initial values.c3dhall12i2c_init- This function initializes all necessary pins and peripherals used for this Click board.c3dhall12i2c_default_cfg- This function executes a default configuration of 3D Hall 12 Click - I2C.c3dhall12i2c_read_data- This function reads the temperature, X, Y, Z magnetic field, angle, and magnitude from the device.

Application Init

Initializes the driver and performs the Click default configuration.

Application Task

Reads data from the sensor approximately every 100ms and displays the measurement values on the USB UART.

Open Source

Code example

The complete application code and a ready-to-use project are available through the NECTO Studio Package Manager for direct installation in the NECTO Studio. The application code can also be found on the MIKROE GitHub account.

/*!

* @file main.c

* @brief 3D Hall 12 I2C Click example

*

* # Description

* This example demonstrates the use of 3D Hall 12 I2C Click board by reading the magnetic

* flux density from 3 axes, and the angle and magnitude between X and Y axes

* as well as the sensor internal temperature.

*

* The demo application is composed of two sections :

*

* ## Application Init

* Initializes the driver and performs the Click default configuration.

*

* ## Application Task

* Reads data from the sensor approximately every 100ms and displays the measurement

* values on the USB UART.

*

* @author Stefan Filipovic

*

*/

#include "board.h"

#include "log.h"

#include "c3dhall12i2c.h"

static c3dhall12i2c_t c3dhall12i2c;

static log_t logger;

void application_init ( void )

{

log_cfg_t log_cfg; /**< Logger config object. */

c3dhall12i2c_cfg_t c3dhall12i2c_cfg; /**< Click config object. */

/**

* Logger initialization.

* Default baud rate: 115200

* Default log level: LOG_LEVEL_DEBUG

* @note If USB_UART_RX and USB_UART_TX

* are defined as HAL_PIN_NC, you will

* need to define them manually for log to work.

* See @b LOG_MAP_USB_UART macro definition for detailed explanation.

*/

LOG_MAP_USB_UART( log_cfg );

log_init( &logger, &log_cfg );

log_info( &logger, " Application Init " );

// Click initialization.

c3dhall12i2c_cfg_setup( &c3dhall12i2c_cfg );

C3DHALL12I2C_MAP_MIKROBUS( c3dhall12i2c_cfg, MIKROBUS_1 );

if ( I2C_MASTER_ERROR == c3dhall12i2c_init( &c3dhall12i2c, &c3dhall12i2c_cfg ) )

{

log_error( &logger, " Communication init." );

for ( ; ; );

}

if ( C3DHALL12I2C_ERROR == c3dhall12i2c_default_cfg ( &c3dhall12i2c ) )

{

log_error( &logger, " Default configuration." );

for ( ; ; );

}

log_info( &logger, " Application Task " );

}

void application_task ( void )

{

c3dhall12i2c_data_t sensor_data;

if ( C3DHALL12I2C_OK == c3dhall12i2c_read_data ( &c3dhall12i2c, &sensor_data ) )

{

log_printf( &logger, " X-axis: %.2f mT\r\n", sensor_data.x );

log_printf( &logger, " Y-axis: %.2f mT\r\n", sensor_data.y );

log_printf( &logger, " Z-axis: %.2f mT\r\n", sensor_data.z );

log_printf( &logger, " Angle: %.1f deg\r\n", sensor_data.angle );

log_printf( &logger, " Magnitude: %.1f\r\n", sensor_data.magnitude );

log_printf( &logger, " Temperature: %.1f degC\r\n\n", sensor_data.temperature );

Delay_ms ( 100 );

}

}

int main ( void )

{

/* Do not remove this line or clock might not be set correctly. */

#ifdef PREINIT_SUPPORTED

preinit();

#endif

application_init( );

for ( ; ; )

{

application_task( );

}

return 0;

}

// ------------------------------------------------------------------------ END

Additional Support

Resources

Category:Magnetic