Elevate your touch experience with a seamlessly integrated touchpad and microcontroller duo, where smoothness meets intelligence for unparalleled user satisfaction

A

A

Hardware Overview

How does it work?

Touchpad 4 Click is based on the IQS7211A, a tiny trackpad controller designed for multitouch applications using a projected capacitance touch panel from Azoteq. The IQS7211A is part of Azoteq’s latest ProxFusion combination sensors, a multi-sensor technology that offers capacitive sensing, Hall-effect, inductive, and temperature sensing combinations on a single integrated circuit. It allows users to control a trackpad of up to 32 channels and offers high resolution and fast response, low power consumption, and long-term activation supported by environmental tracking. It is also characterized by embedded gesture engine recognition for simple gestures (tap, swipes, hold) and built-in noise detection and filtering. On the Touchpad 4 Click front side, a clearly defined field represents a touchpad area. This area is a matrix

of conductive electrodes on the PCB, electrically isolated from each other, arranged as rows and columns of X and Y. An electrode consists of multiple diamond-shaped elements, each connected to the next with a conductive neck. The controller uses the projected capacitance charge transfer principle on the touchpad area. When a conductive object such as a human finger approaches the sense plate, the detected capacitance will decrease. Observing the measured results at various sensing points on the touchpad area enables the controller to determine proximity/hover detection and contact (touch) detection on all channels and accurately determine the coordinates on the touch area. Touchpad 4 Click communicates with MCU using a standard I2C 2-Wire interface, with a clock of

up to 1MHz in the Fast Mode. An additional ready signal, routed on the INT pin of the mikroBUS™ socket, is added, which indicates when the communication window is available. Thus, it is optimal for the response rate to use the INT pin as a communication trigger. Alongside this pin, this Click board™ has a Reset feature routed to the RST pin on the mikroBUS™ socket, which with a low logic level, puts the module into a Reset state, and with a high level, operates the module normally. This Click board™ can be operated only with a 3.3V logic voltage level. The board must perform appropriate logic voltage level conversion before using MCUs with different logic levels. Also, it comes equipped with a library containing functions and an example code that can be used, as a reference, for further development.

Features overview

Development board

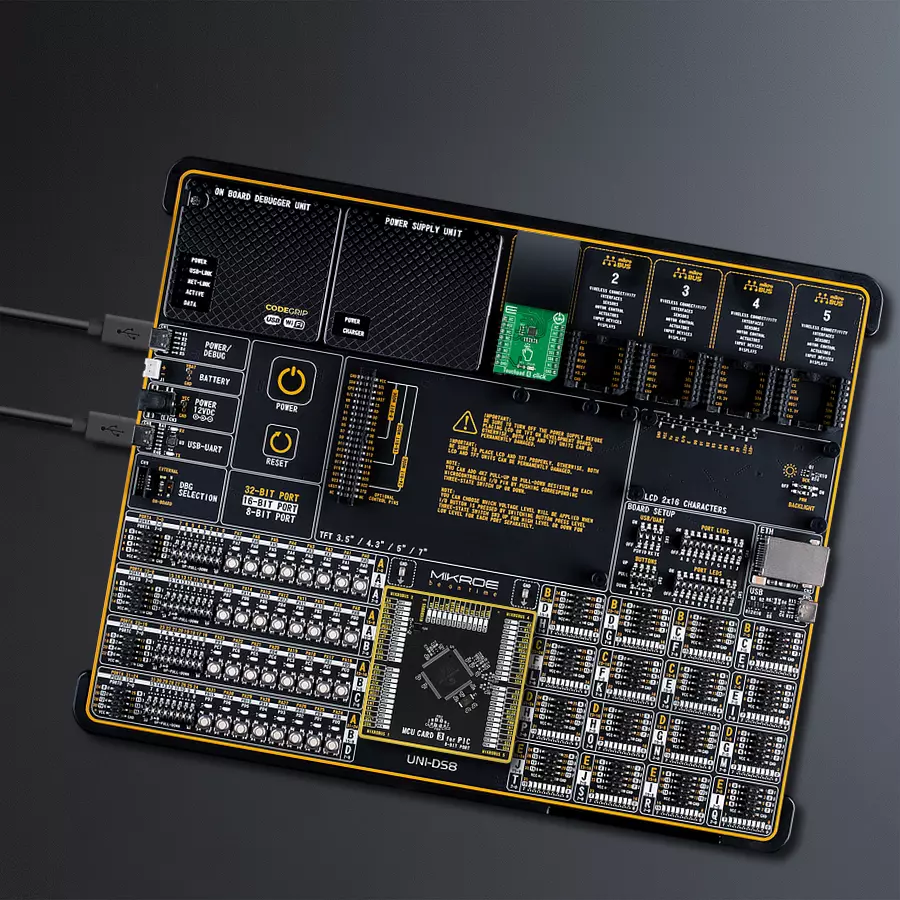

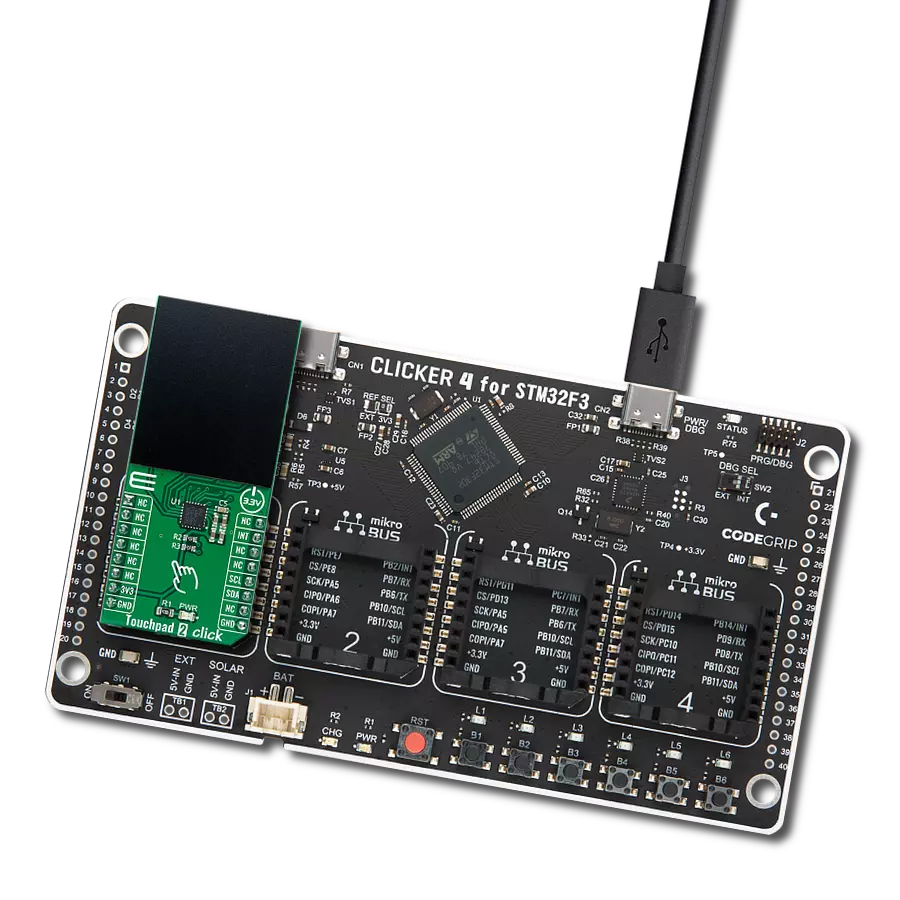

UNI-DS v8 is a development board specially designed for the needs of rapid development of embedded applications. It supports a wide range of microcontrollers, such as different STM32, Kinetis, TIVA, CEC, MSP, PIC, dsPIC, PIC32, and AVR MCUs regardless of their number of pins, and a broad set of unique functions, such as the first-ever embedded debugger/programmer over WiFi. The development board is well organized and designed so that the end-user has all the necessary elements, such as switches, buttons, indicators, connectors, and others, in one place. Thanks to innovative manufacturing technology, UNI-DS v8 provides a fluid and immersive working experience, allowing access anywhere and under any

circumstances at any time. Each part of the UNI-DS v8 development board contains the components necessary for the most efficient operation of the same board. An advanced integrated CODEGRIP programmer/debugger module offers many valuable programming/debugging options, including support for JTAG, SWD, and SWO Trace (Single Wire Output)), and seamless integration with the Mikroe software environment. Besides, it also includes a clean and regulated power supply module for the development board. It can use a wide range of external power sources, including a battery, an external 12V power supply, and a power source via the USB Type-C (USB-C) connector. Communication options such as USB-UART, USB

HOST/DEVICE, CAN (on the MCU card, if supported), and Ethernet is also included. In addition, it also has the well-established mikroBUS™ standard, a standardized socket for the MCU card (SiBRAIN standard), and two display options for the TFT board line of products and character-based LCD. UNI-DS v8 is an integral part of the Mikroe ecosystem for rapid development. Natively supported by Mikroe software tools, it covers many aspects of prototyping and development thanks to a considerable number of different Click boards™ (over a thousand boards), the number of which is growing every day.

Microcontroller Overview

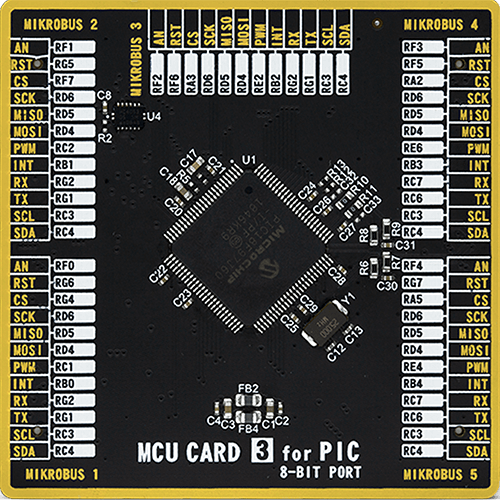

MCU Card / MCU

Type

8th Generation

Architecture

PIC

MCU Memory (KB)

128

Silicon Vendor

Microchip

Pin count

100

RAM (Bytes)

3808

Used MCU Pins

mikroBUS™ mapper

Take a closer look

Click board™ Schematic

Step by step

Project assembly

Track your results in real time

Application Output

1. Application Output - In Debug mode, the 'Application Output' window enables real-time data monitoring, offering direct insight into execution results. Ensure proper data display by configuring the environment correctly using the provided tutorial.

2. UART Terminal - Use the UART Terminal to monitor data transmission via a USB to UART converter, allowing direct communication between the Click board™ and your development system. Configure the baud rate and other serial settings according to your project's requirements to ensure proper functionality. For step-by-step setup instructions, refer to the provided tutorial.

3. Plot Output - The Plot feature offers a powerful way to visualize real-time sensor data, enabling trend analysis, debugging, and comparison of multiple data points. To set it up correctly, follow the provided tutorial, which includes a step-by-step example of using the Plot feature to display Click board™ readings. To use the Plot feature in your code, use the function: plot(*insert_graph_name*, variable_name);. This is a general format, and it is up to the user to replace 'insert_graph_name' with the actual graph name and 'variable_name' with the parameter to be displayed.

Software Support

Library Description

This library contains API for Touchpad 4 Click driver.

Key functions:

touchpad4_reset- Reset functiontouchpad4_get_touch- Read touch informationstouchpad_get_channels- Read channel information

Open Source

Code example

The complete application code and a ready-to-use project are available through the NECTO Studio Package Manager for direct installation in the NECTO Studio. The application code can also be found on the MIKROE GitHub account.

/*!

* @file main.c

* @brief Touchpad4 Click example

*

* # Description

* This example showcases ability of the device to read touch coordinates,

* active/inactive channels, and gesture informations.

*

* The demo application is composed of two sections :

*

* ## Application Init

* Initialize host communication modules(UART and I2C) and additional pins,

* for device control. Then resets device and set default configuration where

* Channels and pins are mapped and configured, and set communication with device

* only on touch/event. In the end one of 3 examples is set;

*

* ## Application Task

* There are 3 examples that shocaes ability of the device:

* - Reading touch coorinates and addinal informations of touch strength,

* and touch area and logging them,

* - Reading channel statuses and show them by logging them,

* - Reading gesture events and logging them;

*

* ### Additional Functions

* - void touchpad4_touch_reading ( void );

* - void touchpad4_channel_reading ( void );

* - void touchpad4_gesture_reading ( void );

*

* @author Luka Filipovic

*

*/

#include "board.h"

#include "log.h"

#include "touchpad4.h"

#define TOUCHPAD4_EXAMPLE_TOUCH 1

#define TOUCHPAD4_EXAMPLE_CHANNEL 2

#define TOUCHPAD4_EXAMPLE_GESTURE 3

static touchpad4_t touchpad4;

static log_t logger;

static uint8_t example_selector = 0;

/**

* @brief Touchpad 4 touch info example.

* @details This function reads touch informations and logs them.

* @return Nothing

*/

void touchpad4_touch_reading ( void );

/**

* @brief Touchpad 4 channel example.

* @details This function reads channel informations and logs them.

* @return Nothing

*/

void touchpad4_channel_reading ( void );

/**

* @brief Touchpad 4 gesture info example.

* @details This function reads gesture informations and logs them.

* @return Nothing

*/

void touchpad4_gesture_reading ( void );

void application_init ( void )

{

log_cfg_t log_cfg; /**< Logger config object. */

touchpad4_cfg_t touchpad4_cfg; /**< Click config object. */

/**

* Logger initialization.

* Default baud rate: 115200

* Default log level: LOG_LEVEL_DEBUG

* @note If USB_UART_RX and USB_UART_TX

* are defined as HAL_PIN_NC, you will

* need to define them manually for log to work.

* See @b LOG_MAP_USB_UART macro definition for detailed explanation.

*/

LOG_MAP_USB_UART( log_cfg );

log_init( &logger, &log_cfg );

log_info( &logger, " Application Init " );

// Click initialization.

touchpad4_cfg_setup( &touchpad4_cfg );

TOUCHPAD4_MAP_MIKROBUS( touchpad4_cfg, MIKROBUS_1 );

err_t init_flag = touchpad4_init( &touchpad4, &touchpad4_cfg );

if ( I2C_MASTER_ERROR == init_flag )

{

log_error( &logger, " Application Init Error. " );

log_info( &logger, " Please, run program again... " );

for ( ; ; );

}

touchpad4_reset( &touchpad4 );

init_flag = touchpad4_default_cfg ( &touchpad4 );

if ( TOUCHPAD4_ERROR == init_flag )

{

log_error( &logger, " Configuration. " );

log_info( &logger, " Please, run program again... " );

for ( ; ; );

}

example_selector = TOUCHPAD4_EXAMPLE_TOUCH;

log_info( &logger, " Application Task " );

}

void application_task ( void )

{

if ( !touchpad4_get_ready( &touchpad4 ) )

{

switch ( example_selector )

{

case TOUCHPAD4_EXAMPLE_TOUCH:

{

touchpad4_touch_reading( );

break;

}

case TOUCHPAD4_EXAMPLE_CHANNEL:

{

touchpad4_channel_reading( );

break;

}

case TOUCHPAD4_EXAMPLE_GESTURE:

{

touchpad4_gesture_reading( );

break;

}

default:

{

log_error( &logger, " Select Example" );

break;

}

}

}

}

int main ( void )

{

/* Do not remove this line or clock might not be set correctly. */

#ifdef PREINIT_SUPPORTED

preinit();

#endif

application_init( );

for ( ; ; )

{

application_task( );

}

return 0;

}

void touchpad4_touch_reading ( void )

{

touchpad4_info_t ti;

touchpad4_get_touch ( &touchpad4, &ti );

if ( ( ti.number_of_touches > 0 ) && ( ti.number_of_touches <= 2 ) )

{

log_printf( &logger, "> X->%d\r\n> Y->%d\r\n> Strength->%u\r\n> Area->%u\r\n",

ti.touches[ 0 ].x, ti.touches[ 0 ].y, ti.touches[ 0 ].strength, ti.touches[ 0 ].area );

log_printf( &logger, "**************\r\n" );

}

}

void touchpad4_channel_reading ( void )

{

uint32_t ch_status = 0;

touchpad_get_channels( &touchpad4, &ch_status );

uint8_t shift = 19;

uint8_t row[ 10 ] = { 0 };

for ( uint8_t r = 0; r < 5; r++ )

{

uint8_t row_char_cnt = 6;

for ( uint8_t y = 0; y < 4; y++ )

{

if ( y )

{

row[ row_char_cnt-- ] = '|';

}

if ( ( ch_status >> shift ) & 1 )

{

row[ row_char_cnt-- ] = 'x';

}

else

{

row[ row_char_cnt-- ] = 'o';

}

shift--;

}

log_printf( &logger, "%s\r\n", row );

}

log_printf( &logger, "\r\n" );

}

void touchpad4_gesture_reading ( void )

{

uint16_t gesture_data = 0;

touchpad4_generic_read( &touchpad4, TOUCHPAD4_REG_GESTURES, &gesture_data );

gesture_data &= 0x003F;

if ( gesture_data & 0x0001 )

{

log_printf( &logger, " > Single Tap <\r\n" );

}

if ( gesture_data & 0x0002 )

{

log_printf( &logger, " > Press And Hold <\r\n" );

}

if ( gesture_data & 0x0004 )

{

log_printf( &logger, " > Swipe X - <\r\n" );

}

if ( gesture_data & 0x0008 )

{

log_printf( &logger, " > Swipe X + <\r\n" );

}

if ( gesture_data & 0x0010 )

{

log_printf( &logger, " > Swipe Y + <\r\n" );

}

if ( gesture_data & 0x0020 )

{

log_printf( &logger, " > Swipe Y - <\r\n" );

}

if ( gesture_data )

{

log_printf( &logger, "**************\r\n" );

}

}

// ------------------------------------------------------------------------ END