Detect changes in vertical magnetic fields and achieve unparalleled sensitivity to specific magnet orientations

A

A

Hardware Overview

How does it work?

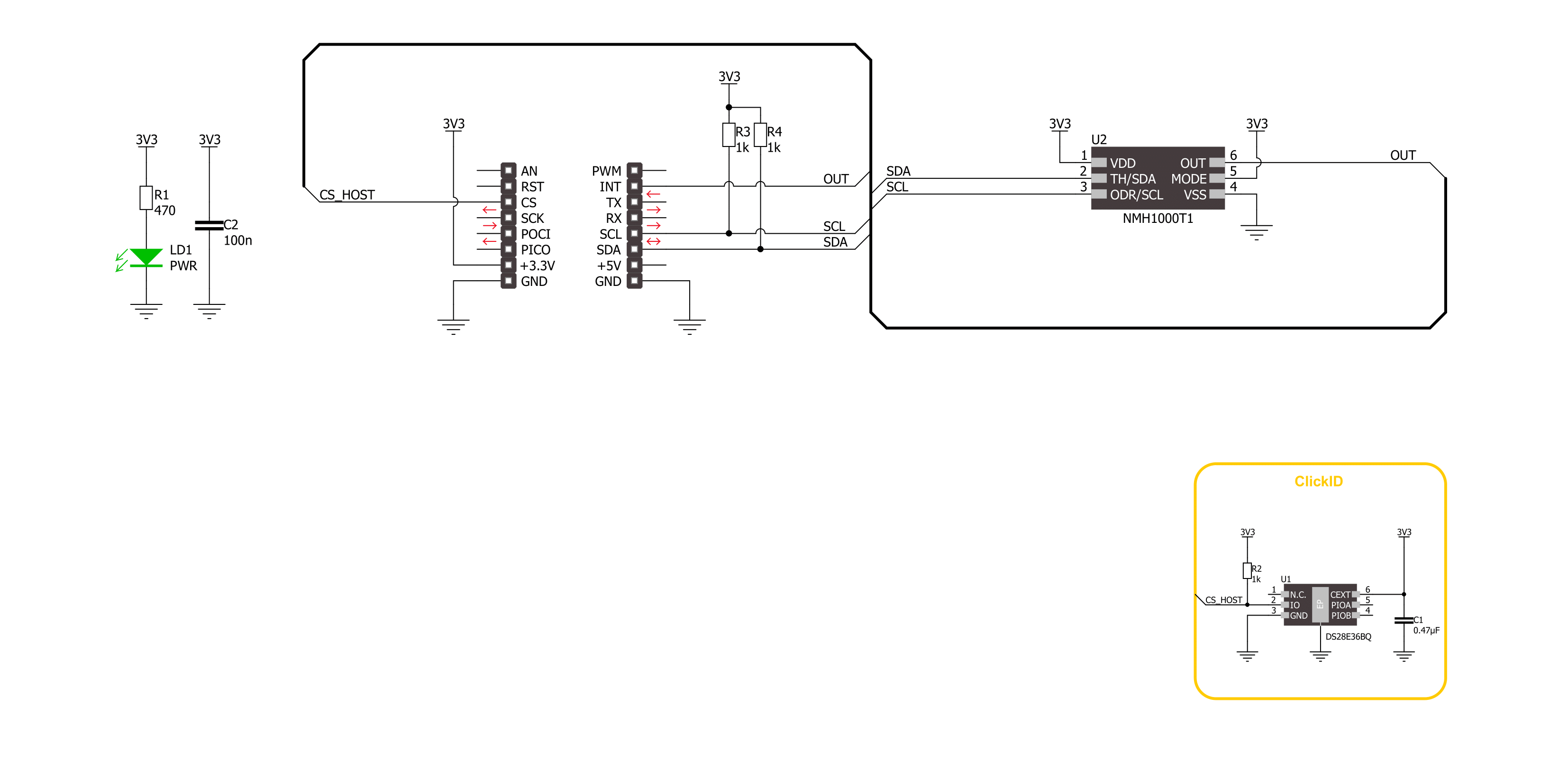

Hall Switch 3 Click is based on the NMH1000, a Hall-effect magnetic switch from NXP Semiconductor. The switch processes its input over the functional blocks that consist of a configurable state machine, an analog-to-voltage conversion of the input, and a comparison to generate the bi-state output. The output is arranged in a linear succession. The NMH1000 has a transducer that generates a small charge proportional to the

proximal magnetic flux density. The Hall-effect charge is converted to voltage and compared with the pre-defined threshold voltage. This determines the state of the switch's output. Hall Switch 3 Click uses a standard 2-wire I2C interface to communicate with the host MCU, supporting a clock frequency of up to 1MHz. The output of the switch, according to the pre-defined threshold, is available over the output OUT pin. This Click

board™ can be operated only with a 3.3V logic voltage level. The board must perform appropriate logic voltage level conversion before using MCUs with different logic levels. Also, it comes equipped with a library containing functions and an example code that can be used as a reference for further development.

Features overview

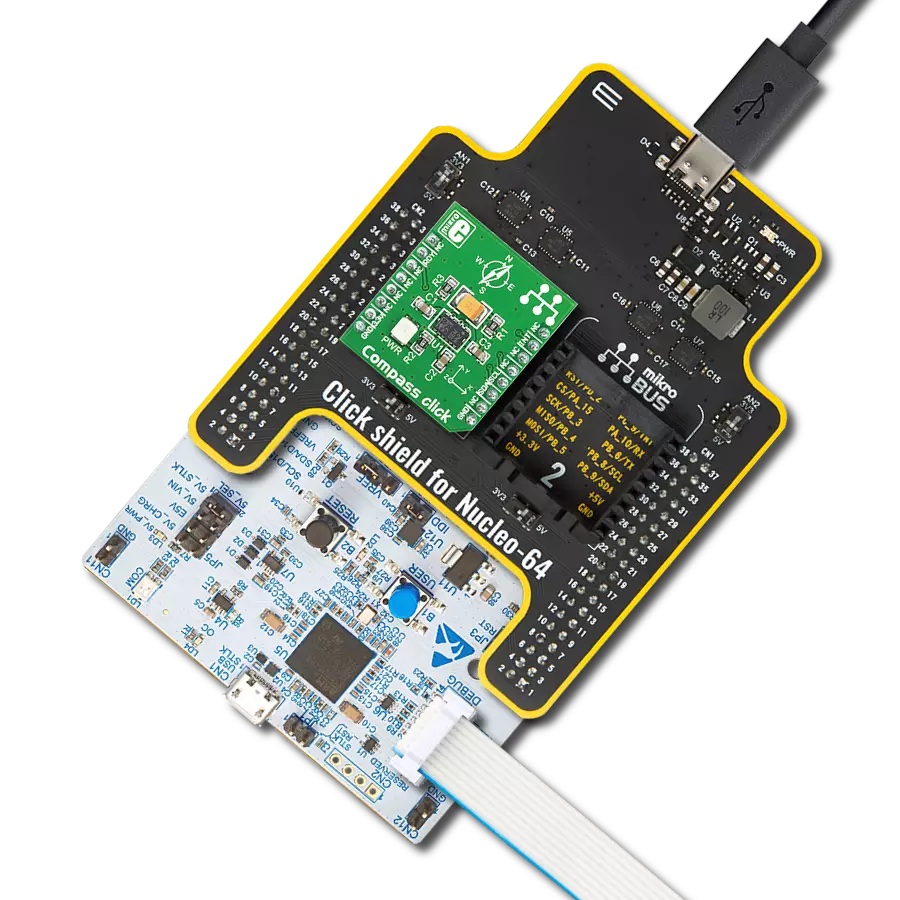

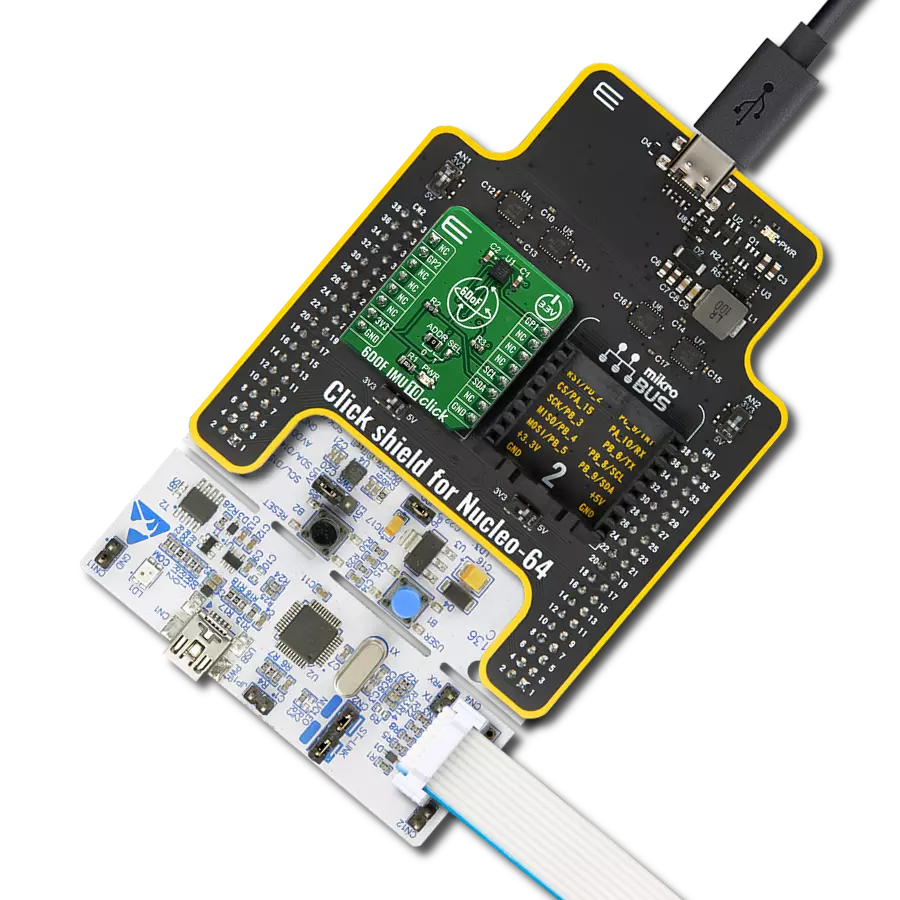

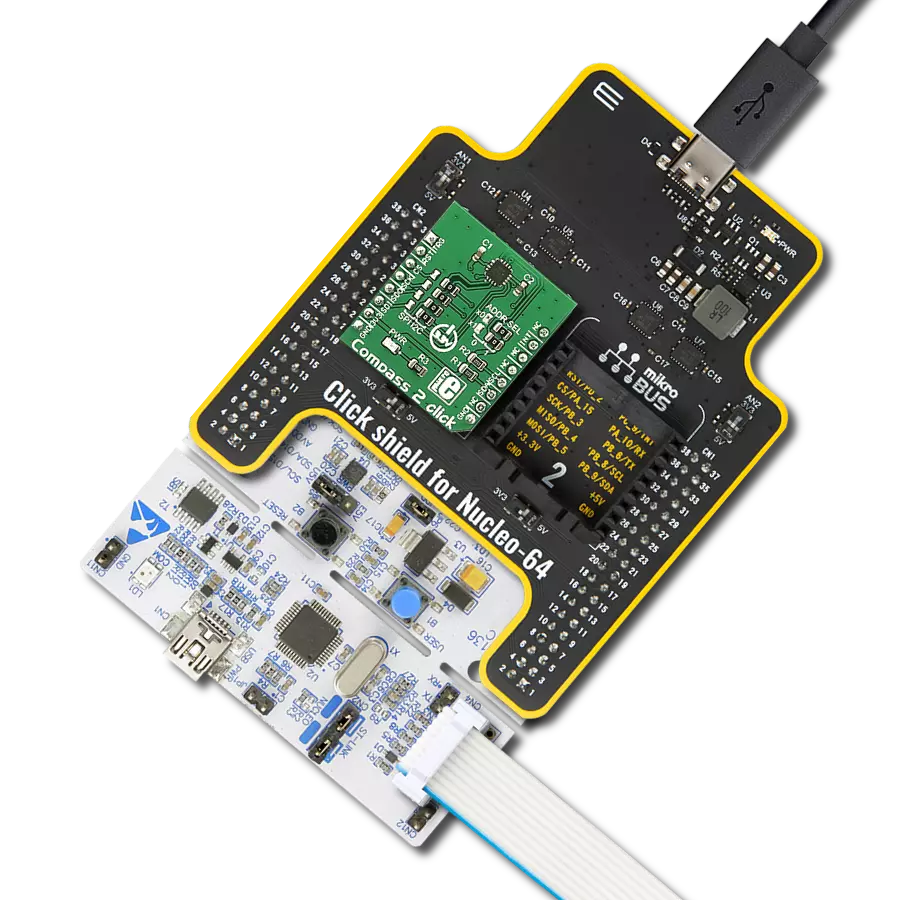

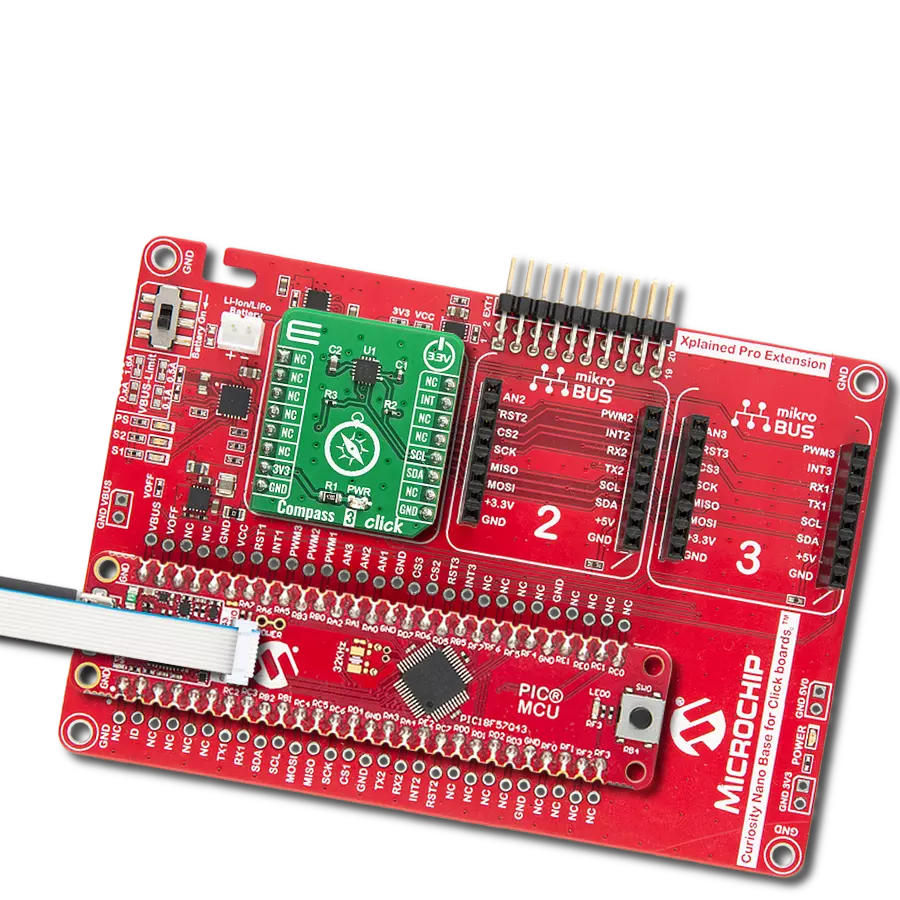

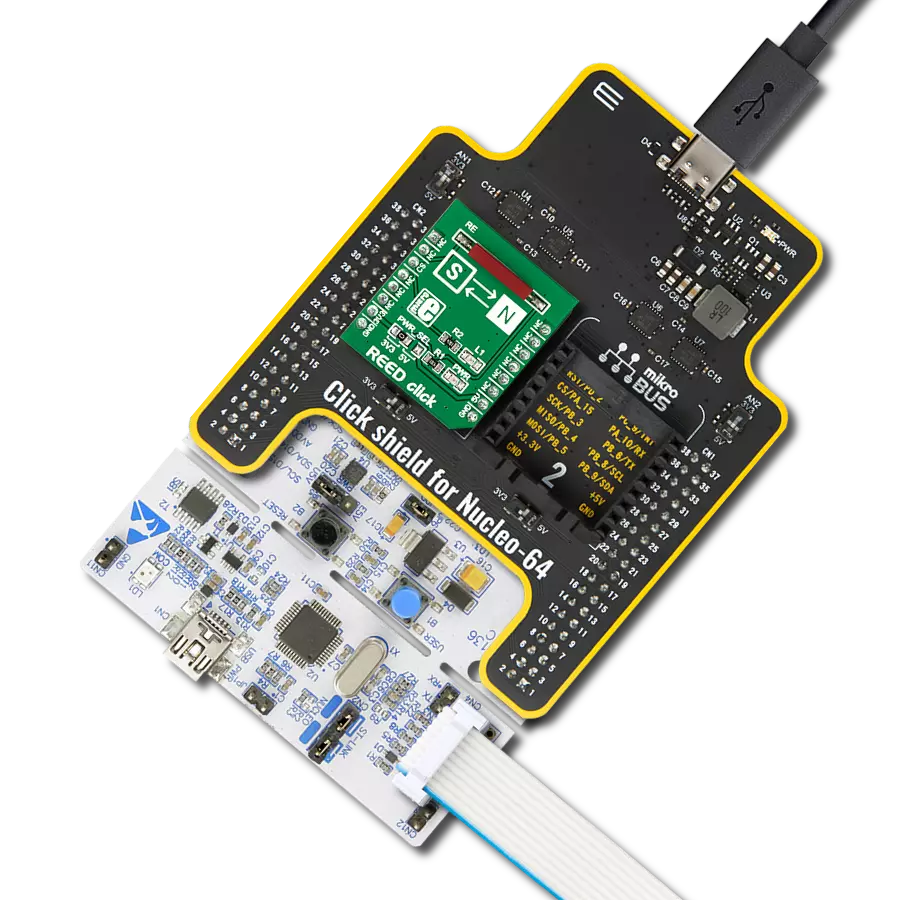

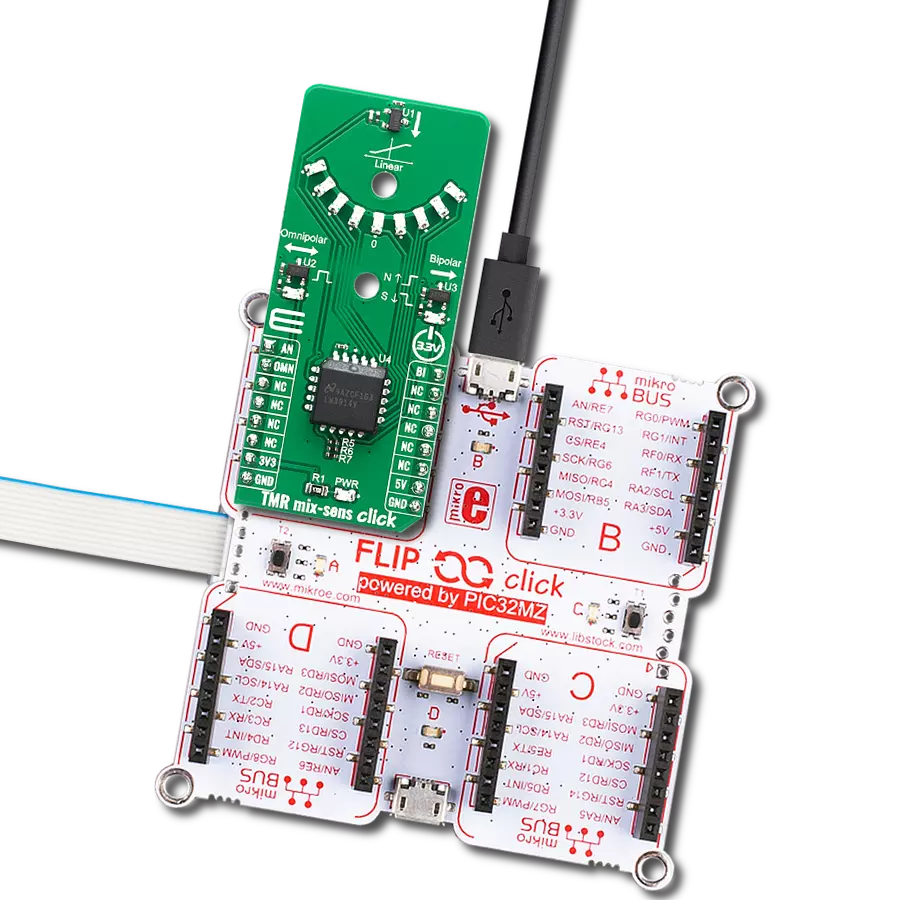

Development board

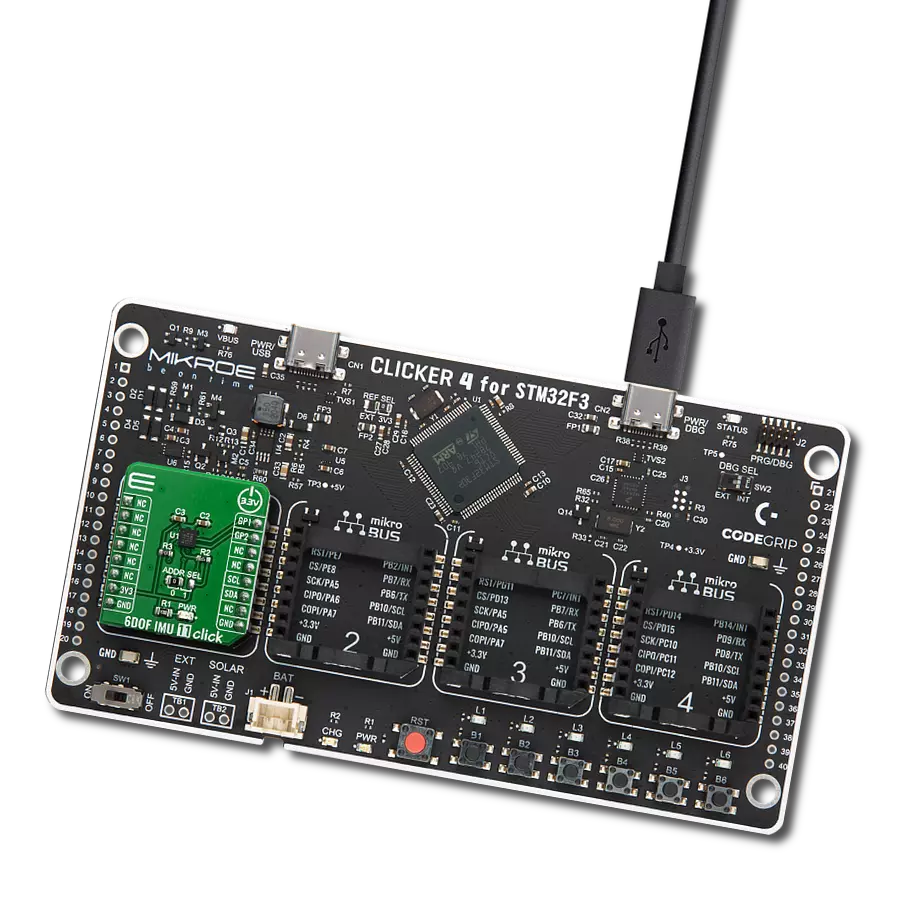

UNI-DS v8 is a development board specially designed for the needs of rapid development of embedded applications. It supports a wide range of microcontrollers, such as different STM32, Kinetis, TIVA, CEC, MSP, PIC, dsPIC, PIC32, and AVR MCUs regardless of their number of pins, and a broad set of unique functions, such as the first-ever embedded debugger/programmer over WiFi. The development board is well organized and designed so that the end-user has all the necessary elements, such as switches, buttons, indicators, connectors, and others, in one place. Thanks to innovative manufacturing technology, UNI-DS v8 provides a fluid and immersive working experience, allowing access anywhere and under any

circumstances at any time. Each part of the UNI-DS v8 development board contains the components necessary for the most efficient operation of the same board. An advanced integrated CODEGRIP programmer/debugger module offers many valuable programming/debugging options, including support for JTAG, SWD, and SWO Trace (Single Wire Output)), and seamless integration with the Mikroe software environment. Besides, it also includes a clean and regulated power supply module for the development board. It can use a wide range of external power sources, including a battery, an external 12V power supply, and a power source via the USB Type-C (USB-C) connector. Communication options such as USB-UART, USB

HOST/DEVICE, CAN (on the MCU card, if supported), and Ethernet is also included. In addition, it also has the well-established mikroBUS™ standard, a standardized socket for the MCU card (SiBRAIN standard), and two display options for the TFT board line of products and character-based LCD. UNI-DS v8 is an integral part of the Mikroe ecosystem for rapid development. Natively supported by Mikroe software tools, it covers many aspects of prototyping and development thanks to a considerable number of different Click boards™ (over a thousand boards), the number of which is growing every day.

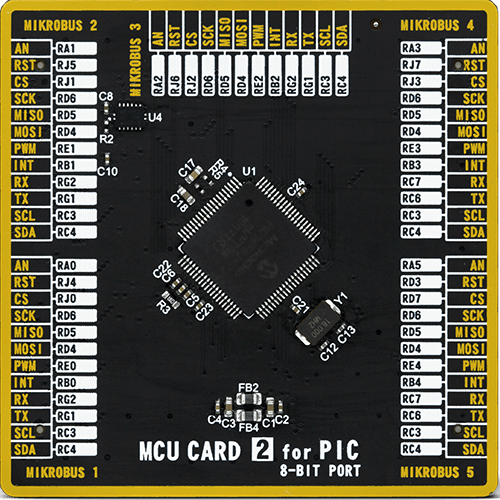

Microcontroller Overview

MCU Card / MCU

Type

8th Generation

Architecture

PIC

MCU Memory (KB)

64

Silicon Vendor

Microchip

Pin count

80

RAM (Bytes)

3862

Used MCU Pins

mikroBUS™ mapper

Take a closer look

Click board™ Schematic

Step by step

Project assembly

Track your results in real time

Application Output

1. Application Output - In Debug mode, the 'Application Output' window enables real-time data monitoring, offering direct insight into execution results. Ensure proper data display by configuring the environment correctly using the provided tutorial.

2. UART Terminal - Use the UART Terminal to monitor data transmission via a USB to UART converter, allowing direct communication between the Click board™ and your development system. Configure the baud rate and other serial settings according to your project's requirements to ensure proper functionality. For step-by-step setup instructions, refer to the provided tutorial.

3. Plot Output - The Plot feature offers a powerful way to visualize real-time sensor data, enabling trend analysis, debugging, and comparison of multiple data points. To set it up correctly, follow the provided tutorial, which includes a step-by-step example of using the Plot feature to display Click board™ readings. To use the Plot feature in your code, use the function: plot(*insert_graph_name*, variable_name);. This is a general format, and it is up to the user to replace 'insert_graph_name' with the actual graph name and 'variable_name' with the parameter to be displayed.

Software Support

Library Description

This library contains API for Hall Switch 3 Click Click driver.

Key functions:

hallswitch3_get_mag_data- This function is used to indicates a relative magnetic field strength.hallswitch3_set_out_data_rate- This function provides the capability for the user to override the fixed sample rate controlling the sleep-compare-Vout cycle time.hallswitch3_get_status- This function reads a status reporting of modes and selections.

Open Source

Code example

The complete application code and a ready-to-use project are available through the NECTO Studio Package Manager for direct installation in the NECTO Studio. The application code can also be found on the MIKROE GitHub account.

/*!

* @file main.c

* @brief Hall Switch 3 Click example

*

* # Description

* This example demonstrates the use of Hall Switch 3 Click board

* by reading and displaying the magnetic field strength value.

*

* The demo application is composed of two sections :

*

* ## Application Init

* Initialization of I2C module and log UART.

* After driver initialization, the app executes a default configuration.

*

* ## Application Task

* This example demonstrates the use of the Hall Switch 3 Click board.

* The demo application reads and displays the relative magnetic field strength value [Gaussian units]

* and detects when the magnetic field strength is not in the configured range.

* The results are sent to the UART terminal, where you can monitor their changes.

*

* @author Nenad Filipovic

*

*/

#include "board.h"

#include "log.h"

#include "hallswitch3.h"

static hallswitch3_t hallswitch3;

static log_t logger;

void application_init ( void )

{

log_cfg_t log_cfg; /**< Logger config object. */

hallswitch3_cfg_t hallswitch3_cfg; /**< Click config object. */

/**

* Logger initialization.

* Default baud rate: 115200

* Default log level: LOG_LEVEL_DEBUG

* @note If USB_UART_RX and USB_UART_TX

* are defined as HAL_PIN_NC, you will

* need to define them manually for log to work.

* See @b LOG_MAP_USB_UART macro definition for detailed explanation.

*/

LOG_MAP_USB_UART( log_cfg );

log_init( &logger, &log_cfg );

log_info( &logger, " Application Init " );

// Click initialization.

hallswitch3_cfg_setup( &hallswitch3_cfg );

HALLSWITCH3_MAP_MIKROBUS( hallswitch3_cfg, MIKROBUS_1 );

if ( I2C_MASTER_ERROR == hallswitch3_init( &hallswitch3, &hallswitch3_cfg ) )

{

log_error( &logger, " Communication init." );

for ( ; ; );

}

if ( HALLSWITCH3_ERROR == hallswitch3_default_cfg ( &hallswitch3 ) )

{

log_error( &logger, " Default configuration." );

for ( ; ; );

}

log_info( &logger, " Application Task " );

}

void application_task ( void )

{

int8_t mag_data = 0;

if ( HALLSWITCH3_OK == hallswitch3_get_mag_data( &hallswitch3, &mag_data ) )

{

log_printf( &logger, " Magnetic Field: %d [Gs]\r\n", ( int16_t ) mag_data );

if ( HALLSWITCH3_OUT_STATE_LOW == hallswitch3_check_mag_field( &hallswitch3 ) )

{

log_printf( &logger, " The switch is open.\r\n" );

}

}

Delay_ms ( 1000 );

}

int main ( void )

{

/* Do not remove this line or clock might not be set correctly. */

#ifdef PREINIT_SUPPORTED

preinit();

#endif

application_init( );

for ( ; ; )

{

application_task( );

}

return 0;

}

// ------------------------------------------------------------------------ END