Discover a new realm of possibilities as you delve into the art and science of color sensing with our innovative solution

A

A

Hardware Overview

How does it work?

Color 7 Click is based on the TCS3472 color light to digital converter with IR filter, from ams OSRAM. The color sensor is made out of a 4x3 matrix of photosensitive elements - photodiodes, which are placed under red, green, and blue colored filters. One group of photodiodes has no color filter, thus sensing the clear light. All the photodiodes are coated with an IR resistive layer, which prevents the influence of the IR part of the spectrum on the color readings. Besides the color sensing elements, the TCS3472 has four 16bit ADCs that convert the photodiode current into a 16bit value, available for reading. Finally, the TCS3472 IC contains a state machine, which controls the operation of the IC. After the Power ON reset, the device is set in the low power mode (Sleep mode). An I2C Start condition will wake up the device and it transitions to the Idle state. After checking the content of the Enable register PON bit. If set, the device will resume in Idle mode, and after setting the AEN bit of the Enable register, the sampling cycle is started. Another bit (WEN) determines if the device will start in Wait mode, or it will start the sampling cycle, with the integration time, defined by the user firmware. Integration time affects the sensitivity and the resolution of ADCs.

After the conversion is complete, the device returns to idle state, repeating the whole cycle, depending on the states of these bits. There are two modes of measurement available on this Click board™. It can use the CONT (continuous measurement), or the CMD (single measurement) measurement modes. The CONT mode outputs data continuously, using a time delay determined by the content of the BREAK register, while the CMD mode allows one measurement to be performed per command. After a single measurement is performed, the device can fall back to the Power Down or Standby state, while working in CMD mode. This is determined by the appropriate bits in the configuration registers and allows for a lower power consumption if required by the application. The interrupt engine allows low and high thresholds to be defined. The conversion value is compared with values set as the low and high threshold, and if any of the threshold values is exceeded, the interrupt event will be generated. The interrupt will assert the INT pin of the IC, routed to the mikroBUS™ INT pin. The interrupt pin will remain asserted until host clears the interrupt flag by the appropriate command. Another interrupt engine feature is the

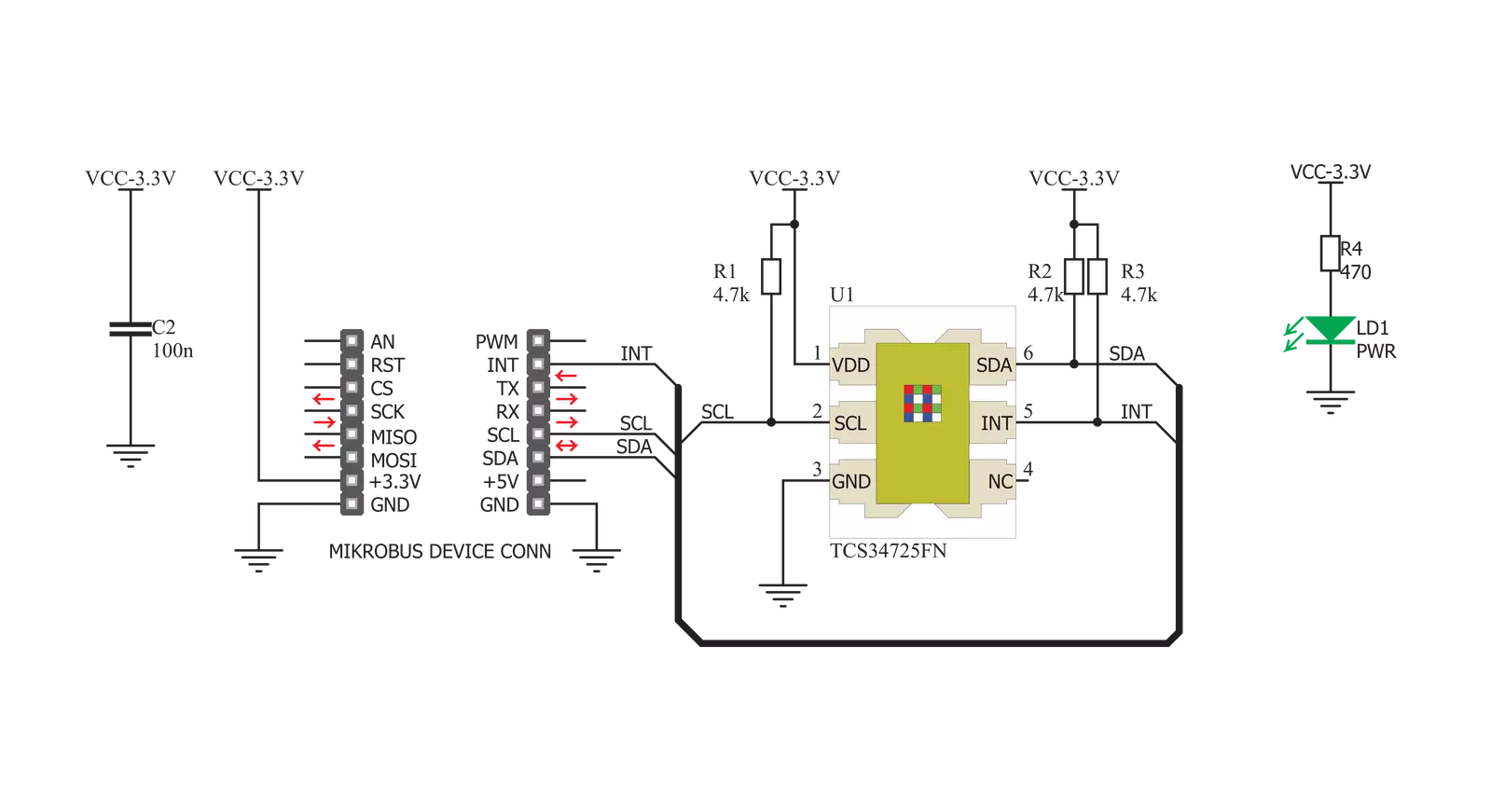

persistence filter. This allows the number of the consecutive threshold exceed occurrences to be made before triggering an interrupt, avoiding erratic or false interrupt triggering. This pin is an open drain topology, and when asserted, it will be driven to a LOW logic state. It is set to a HIGH state when inactive, by the pull-up resistor. The Click board™ itself uses a very low number of external components. In fact, it only uses a few resistors for pulling the I2C/INT lines to a HIGH logic level when not asserted. The low number of external components simplify the design with this IC, allowing it to be used in a wide range of applications. I2C bus lines are routed to the appropriate mikroBUS™ pins, offering simple and reliable interfacing with the host MCU. Please note that this Click board™ can work only with 3.3V MCUs and it is not 5V tolerant. The device datasheet contains all the necessary information about the registers and their values. However, the Click board™ comes supported by a library, which contains functions which greatly simplify the development of the applications, cutting time to market.

Features overview

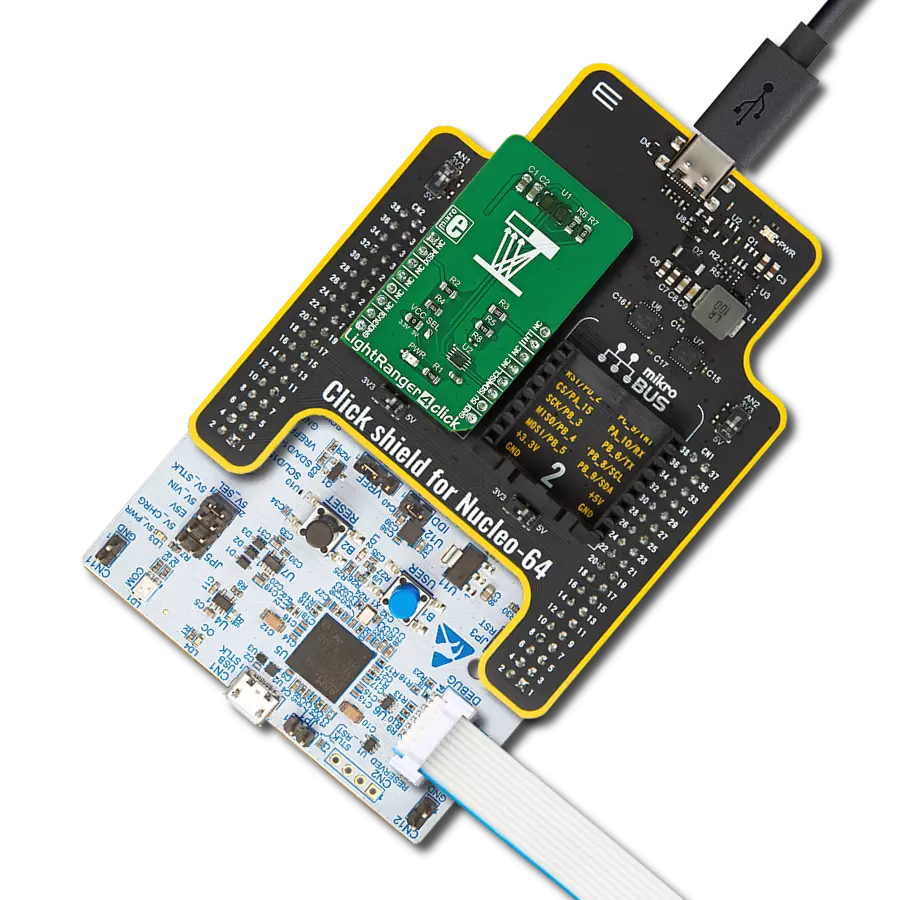

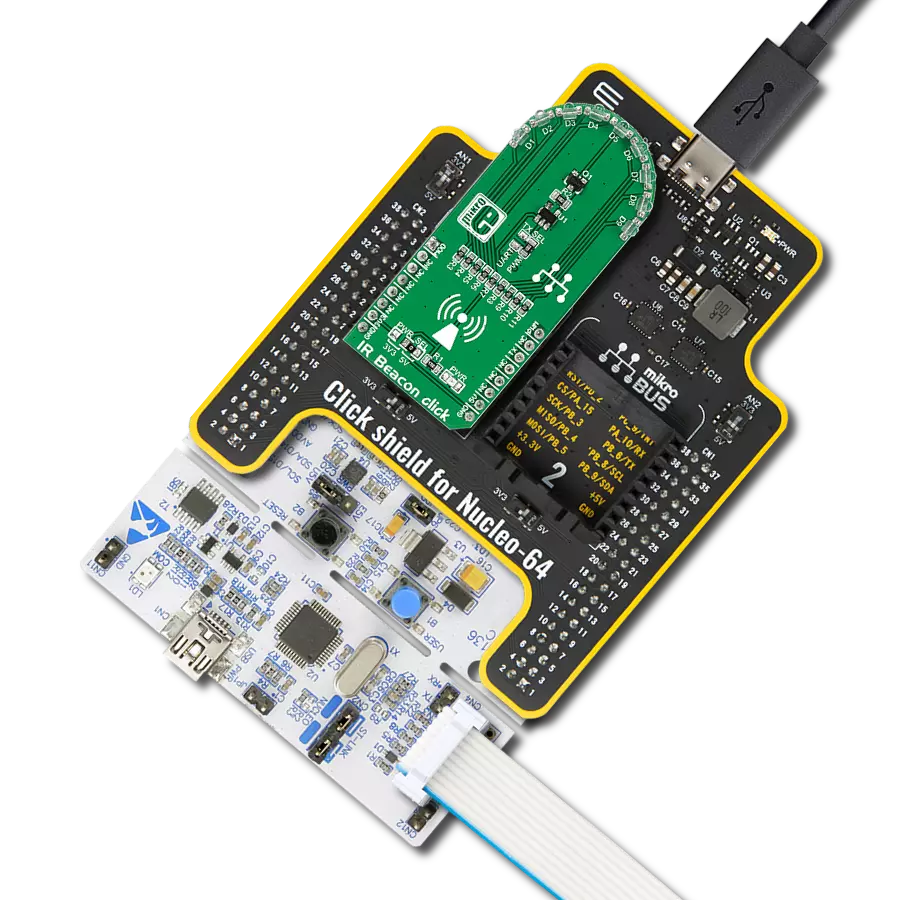

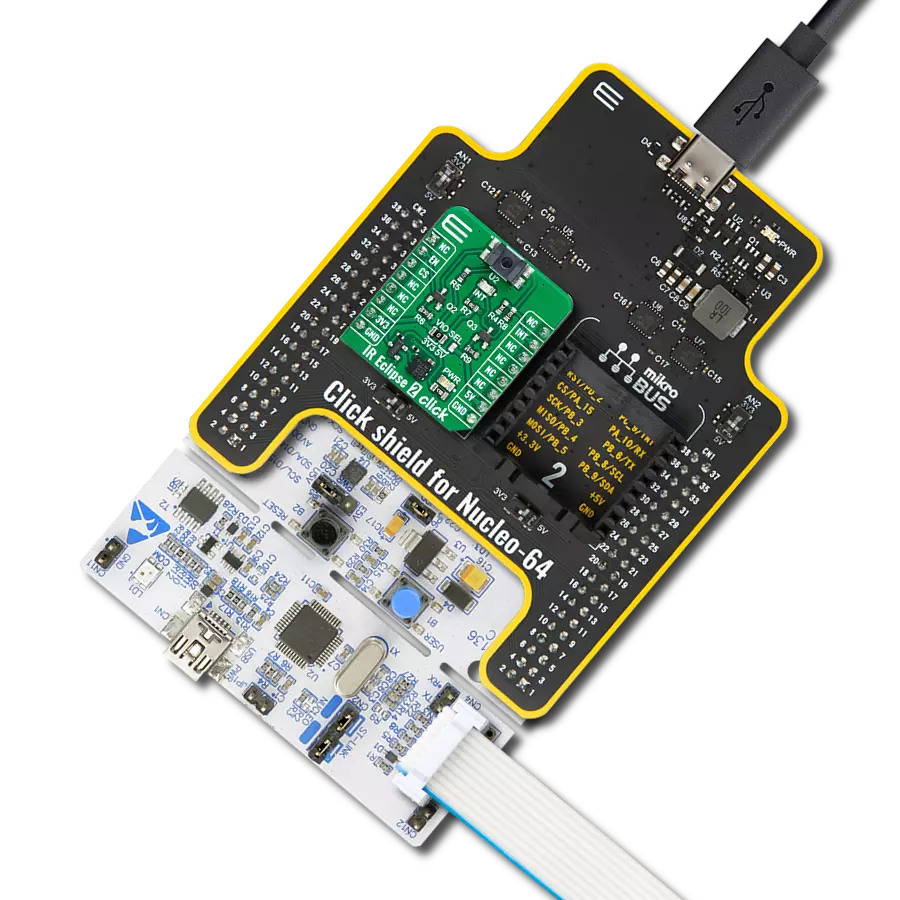

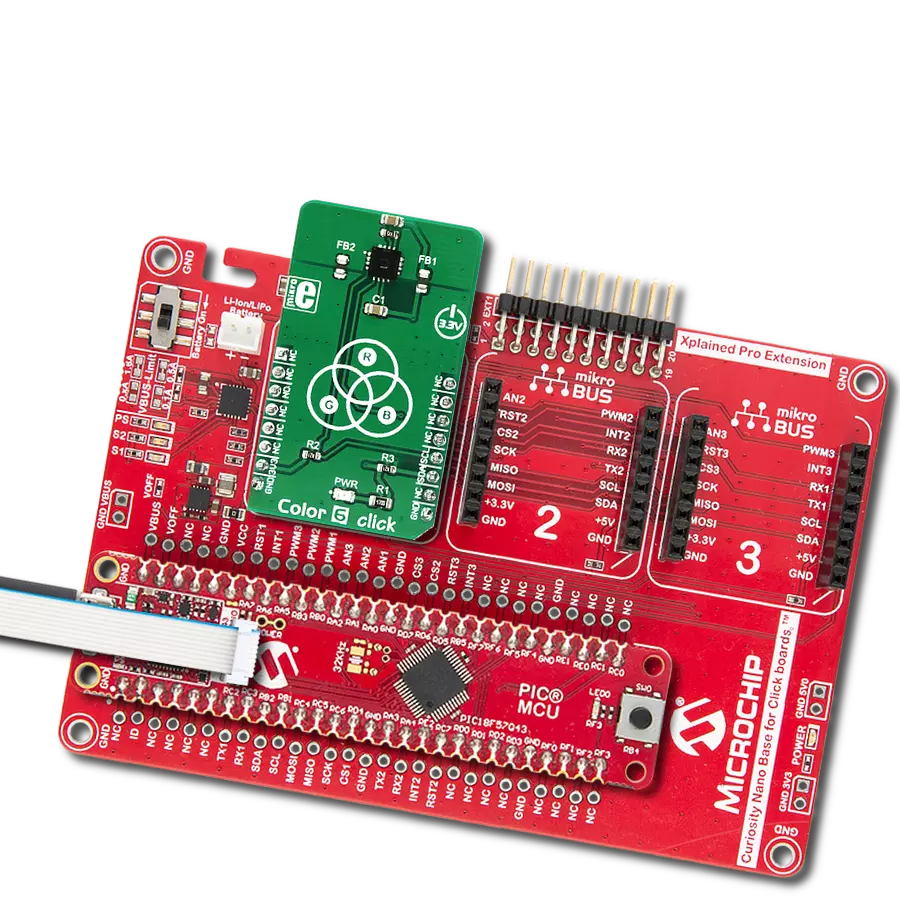

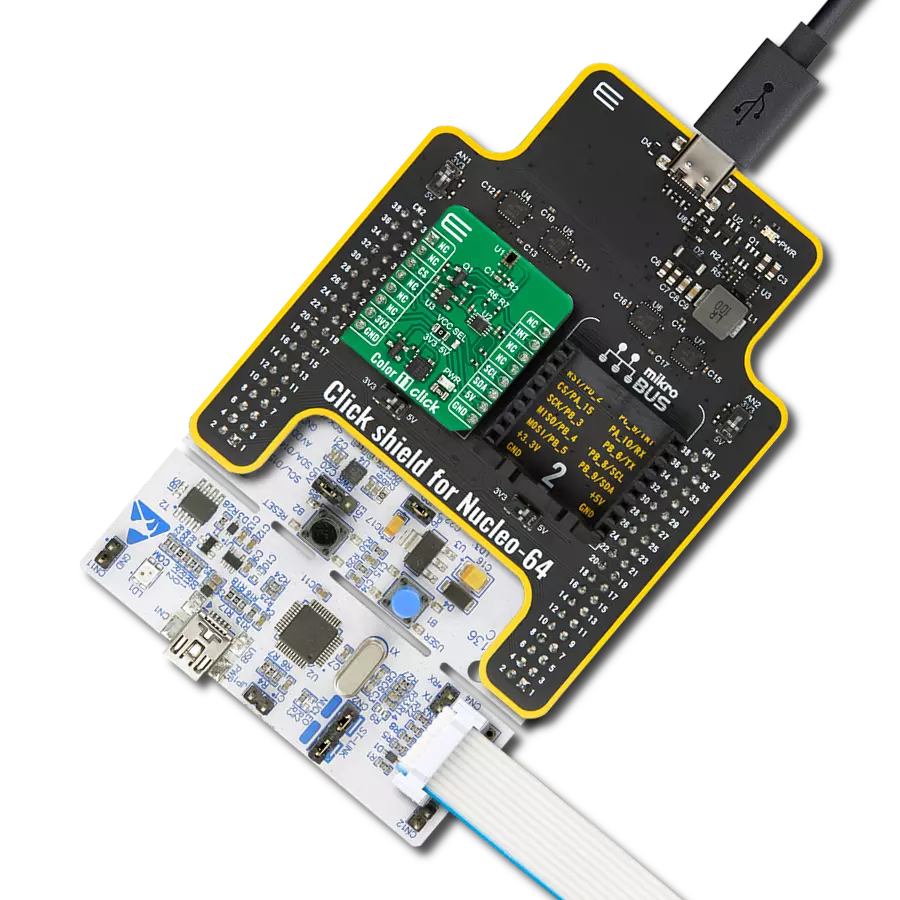

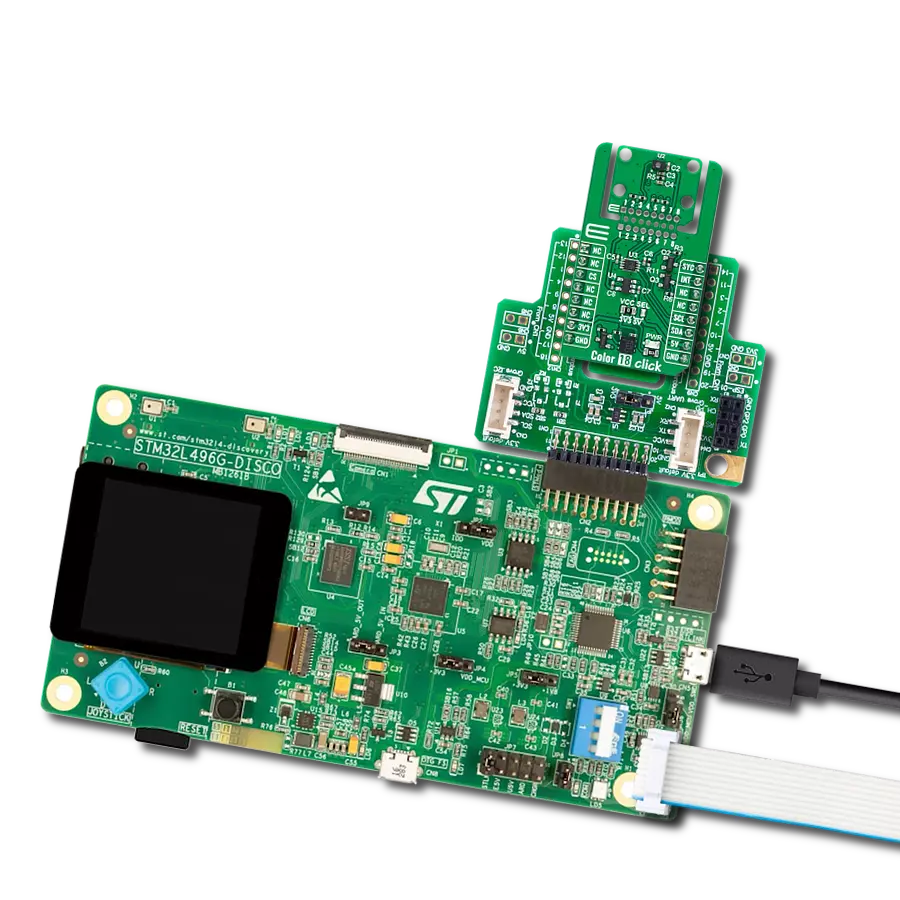

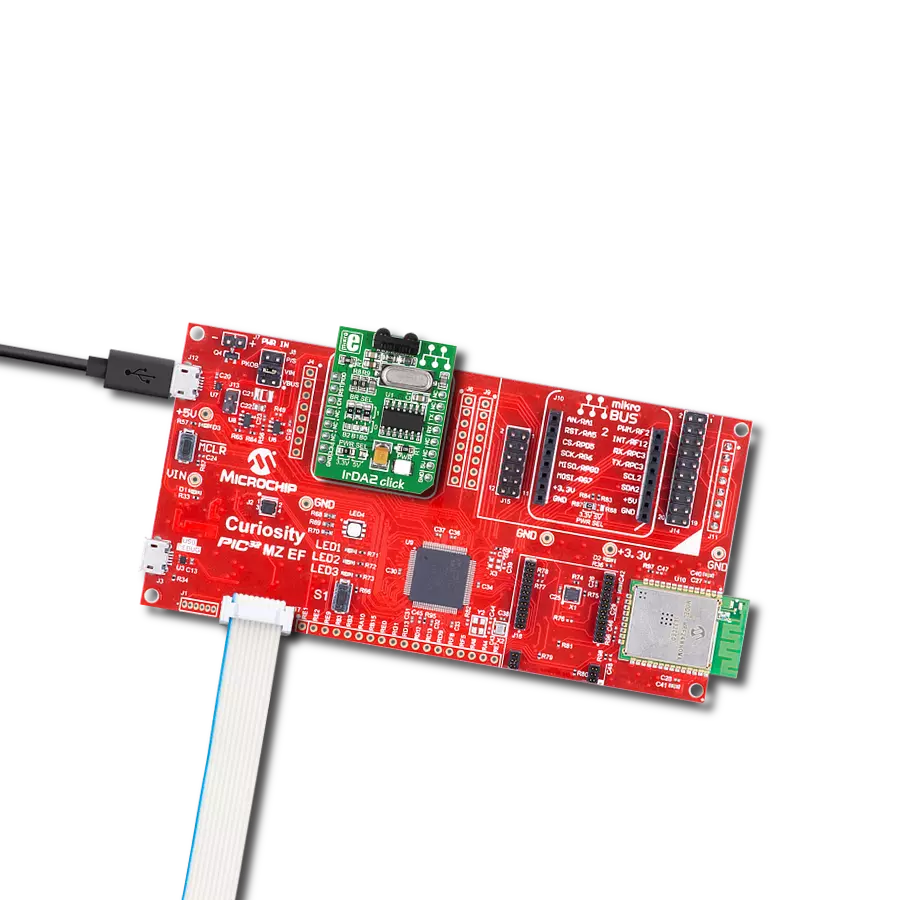

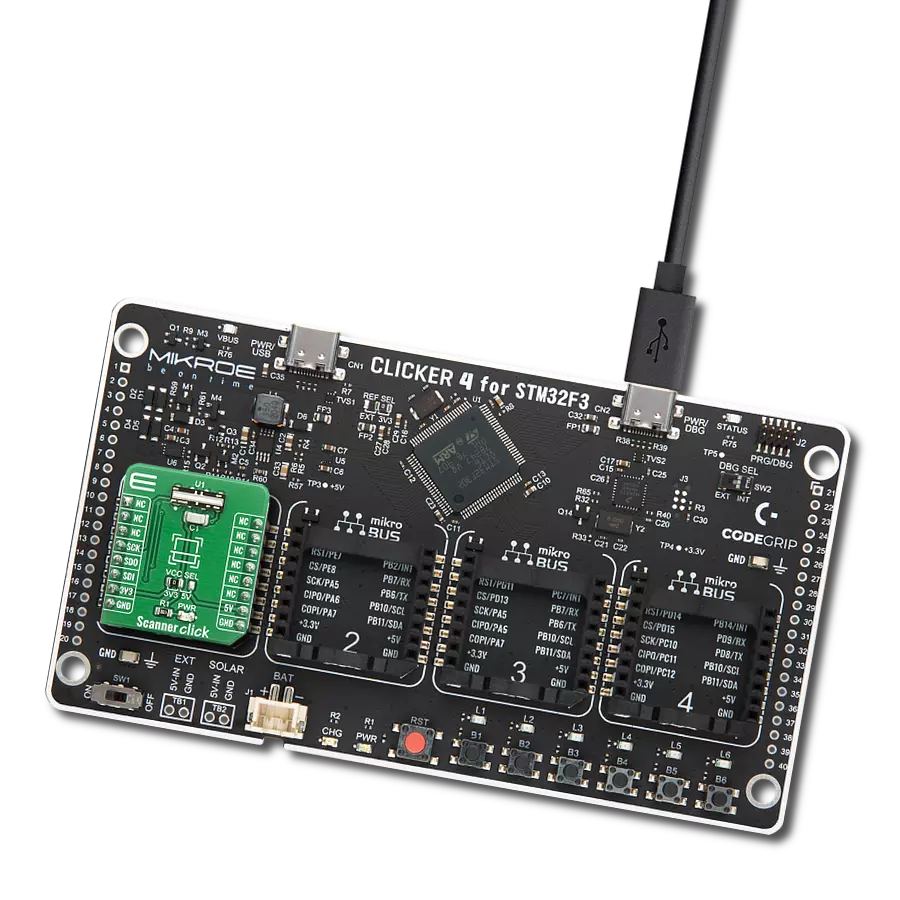

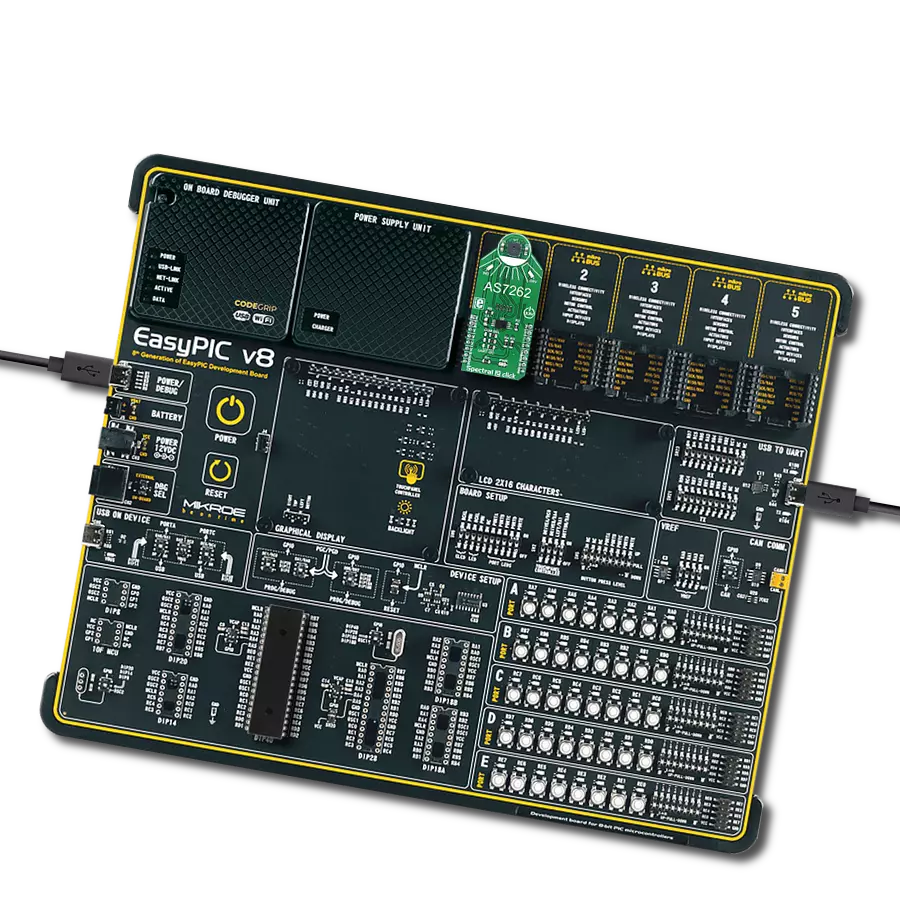

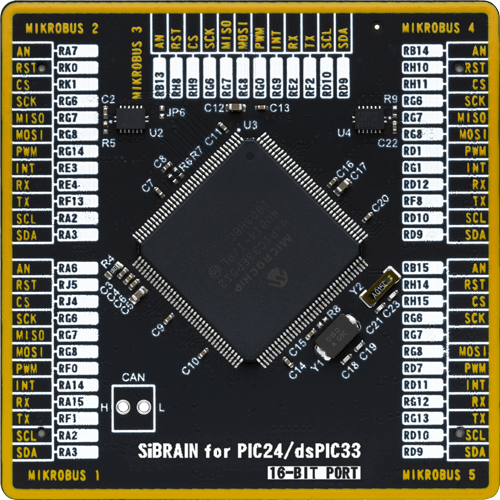

Development board

UNI-DS v8 is a development board specially designed for the needs of rapid development of embedded applications. It supports a wide range of microcontrollers, such as different STM32, Kinetis, TIVA, CEC, MSP, PIC, dsPIC, PIC32, and AVR MCUs regardless of their number of pins, and a broad set of unique functions, such as the first-ever embedded debugger/programmer over WiFi. The development board is well organized and designed so that the end-user has all the necessary elements, such as switches, buttons, indicators, connectors, and others, in one place. Thanks to innovative manufacturing technology, UNI-DS v8 provides a fluid and immersive working experience, allowing access anywhere and under any

circumstances at any time. Each part of the UNI-DS v8 development board contains the components necessary for the most efficient operation of the same board. An advanced integrated CODEGRIP programmer/debugger module offers many valuable programming/debugging options, including support for JTAG, SWD, and SWO Trace (Single Wire Output)), and seamless integration with the Mikroe software environment. Besides, it also includes a clean and regulated power supply module for the development board. It can use a wide range of external power sources, including a battery, an external 12V power supply, and a power source via the USB Type-C (USB-C) connector. Communication options such as USB-UART, USB

HOST/DEVICE, CAN (on the MCU card, if supported), and Ethernet is also included. In addition, it also has the well-established mikroBUS™ standard, a standardized socket for the MCU card (SiBRAIN standard), and two display options for the TFT board line of products and character-based LCD. UNI-DS v8 is an integral part of the Mikroe ecosystem for rapid development. Natively supported by Mikroe software tools, it covers many aspects of prototyping and development thanks to a considerable number of different Click boards™ (over a thousand boards), the number of which is growing every day.

Microcontroller Overview

MCU Card / MCU

Type

8th Generation

Architecture

dsPIC

MCU Memory (KB)

512

Silicon Vendor

Microchip

Pin count

144

RAM (Bytes)

53248

Used MCU Pins

mikroBUS™ mapper

Take a closer look

Click board™ Schematic

Step by step

Project assembly

Software Support

Library Description

This library contains API for Color 7 Click driver.

Key functions:

color7_get_color- Functions for detect colorscolor7_get_interrupt_state- Get interrut pin statecolor7_read_color_ratio- Functions for read color ratio

Open Source

Code example

The complete application code and a ready-to-use project are available through the NECTO Studio Package Manager for direct installation in the NECTO Studio. The application code can also be found on the MIKROE GitHub account.

/*!

* \file

* \brief Color7 Click example

*

* # Description

* Demo application reads and detects colors - detected color logs on USBUART.

*

* The demo application is composed of two sections :

*

* ## Application Init

* Configuring Clicks and log objects.

* Settings the Click in the default configuration.

*

* ## Application Task

* Reads light color and checks which color of light is detected by the sensor

* If the light color is detected, the detected color message is logged on the USBUART.

*

* *note:*

* Light source must be pointed towards sensor in order for sensor to

* detect light source color correctly.

* We used the HSL color palette on the monitor as an example.

*

* \author Katarina Perendic

*

*/

// ------------------------------------------------------------------- INCLUDES

#include "board.h"

#include "log.h"

#include "color7.h"

// ------------------------------------------------------------------ VARIABLES

static color7_t color7;

static log_t logger;

// ------------------------------------------------------ APPLICATION FUNCTIONS

void application_init ( void )

{

log_cfg_t log_cfg;

color7_cfg_t cfg;

/**

* Logger initialization.

* Default baud rate: 115200

* Default log level: LOG_LEVEL_DEBUG

* @note If USB_UART_RX and USB_UART_TX

* are defined as HAL_PIN_NC, you will

* need to define them manually for log to work.

* See @b LOG_MAP_USB_UART macro definition for detailed explanation.

*/

LOG_MAP_USB_UART( log_cfg );

log_init( &logger, &log_cfg );

log_info( &logger, "---- Application Init ----" );

// Click initialization.

color7_cfg_setup( &cfg );

COLOR7_MAP_MIKROBUS( cfg, MIKROBUS_1 );

color7_init( &color7, &cfg );

color7_default_cfg( &color7 );

log_info( &logger, "---- Start measurement ----" );

}

void application_task ( void )

{

uint8_t color;

// Task implementation.

color = color7_get_color( &color7 );

switch( color )

{

case 1:

{

log_printf( &logger, "--- Color: ORANGE \r\n" );

break;

}

case 2:

{

log_printf( &logger, "--- Color: RED \r\n" );

break;

}

case 3:

{

log_printf( &logger, "--- Color: PINK \r\n" );

break;

}

case 4:

{

log_printf( &logger, "--- Color: PURPLE \r\n" );

break;

}

case 5:

{

log_printf( &logger, "--- Color: BLUE \r\n" );

break;

}

case 6:

{

log_printf( &logger, "--- Color: CYAN \r\n" );

break;

}

case 7:

{

log_printf( &logger, "--- Color: GREEN \r\n" );

break;

}

case 8:

{

log_printf( &logger, "--- Color: YELLOW \r\n" );

break;

}

default:

{

// log_printf( &logger, "--- Color: UNRECOGNIZABLE \r\n" );

break;

}

}

Delay_100ms();

}

int main ( void )

{

/* Do not remove this line or clock might not be set correctly. */

#ifdef PREINIT_SUPPORTED

preinit();

#endif

application_init( );

for ( ; ; )

{

application_task( );

}

return 0;

}

// ------------------------------------------------------------------------ END