Designed to enhance user interaction and control, this advanced sensor device empowers developers to create innovative products with touch-sensitive capabilities and accurate magnetic angle detection

A

A

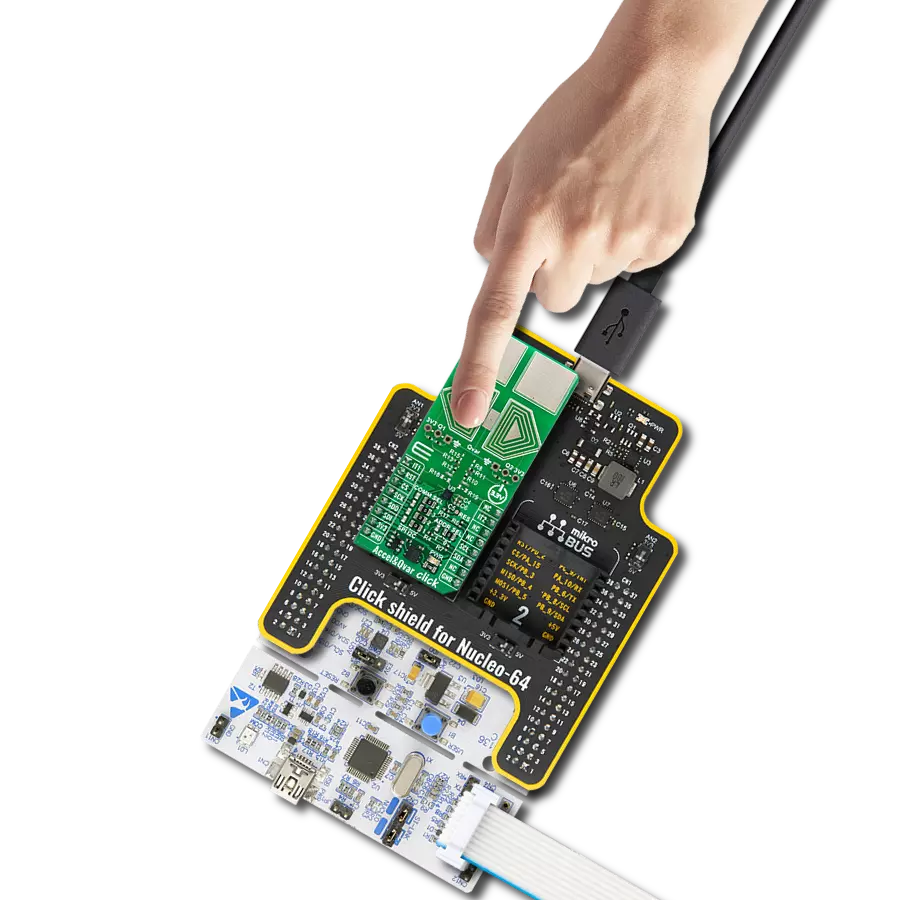

Hardware Overview

How does it work?

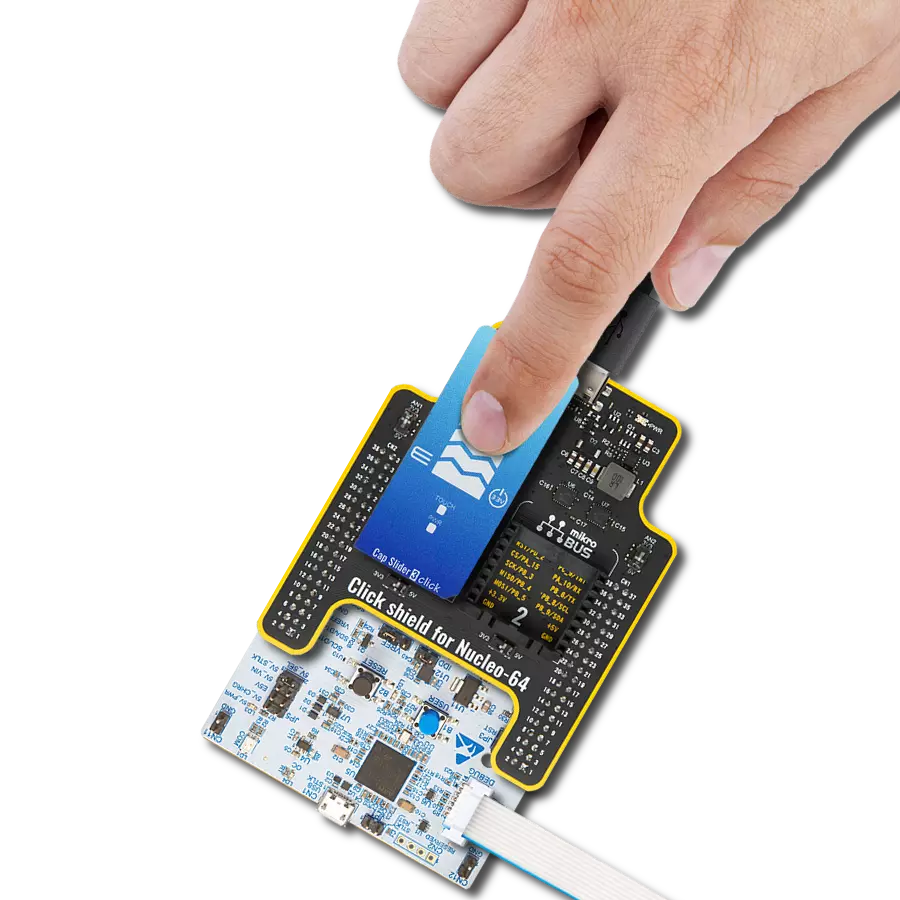

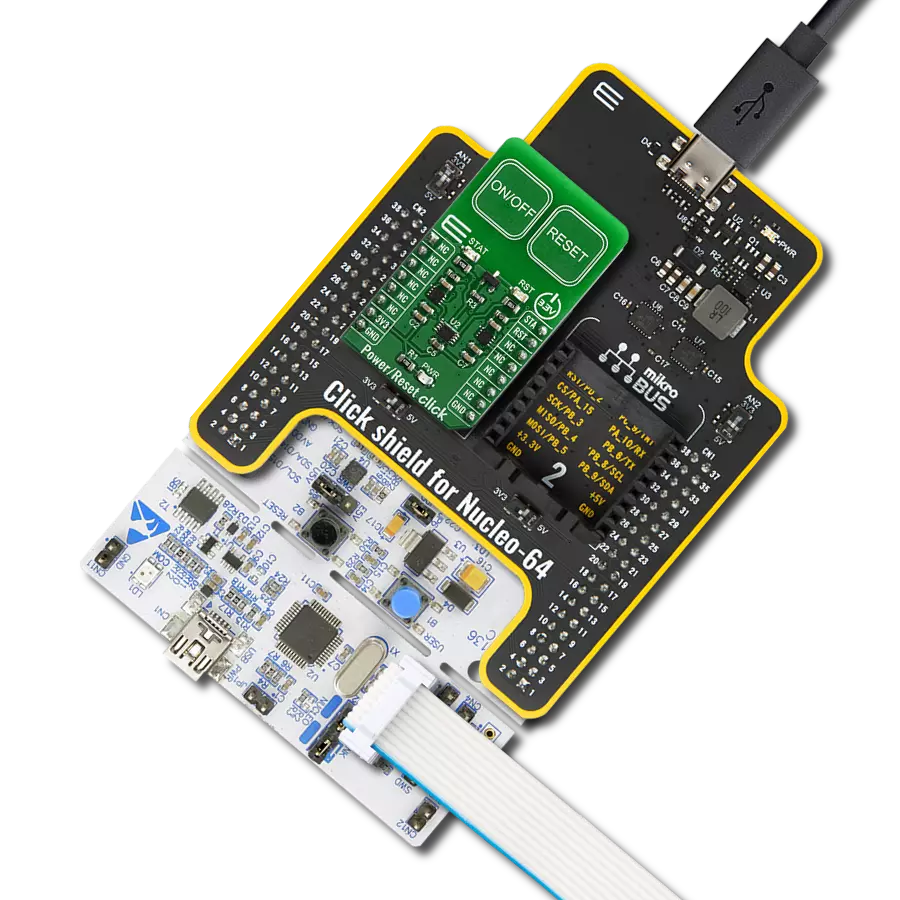

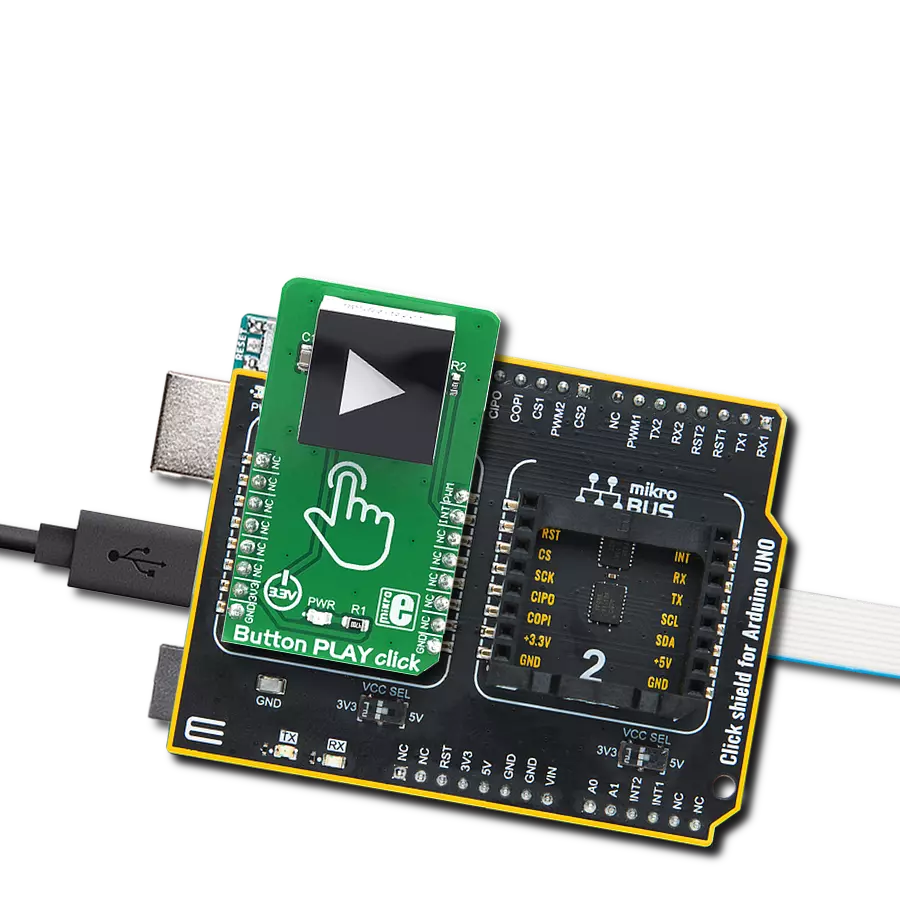

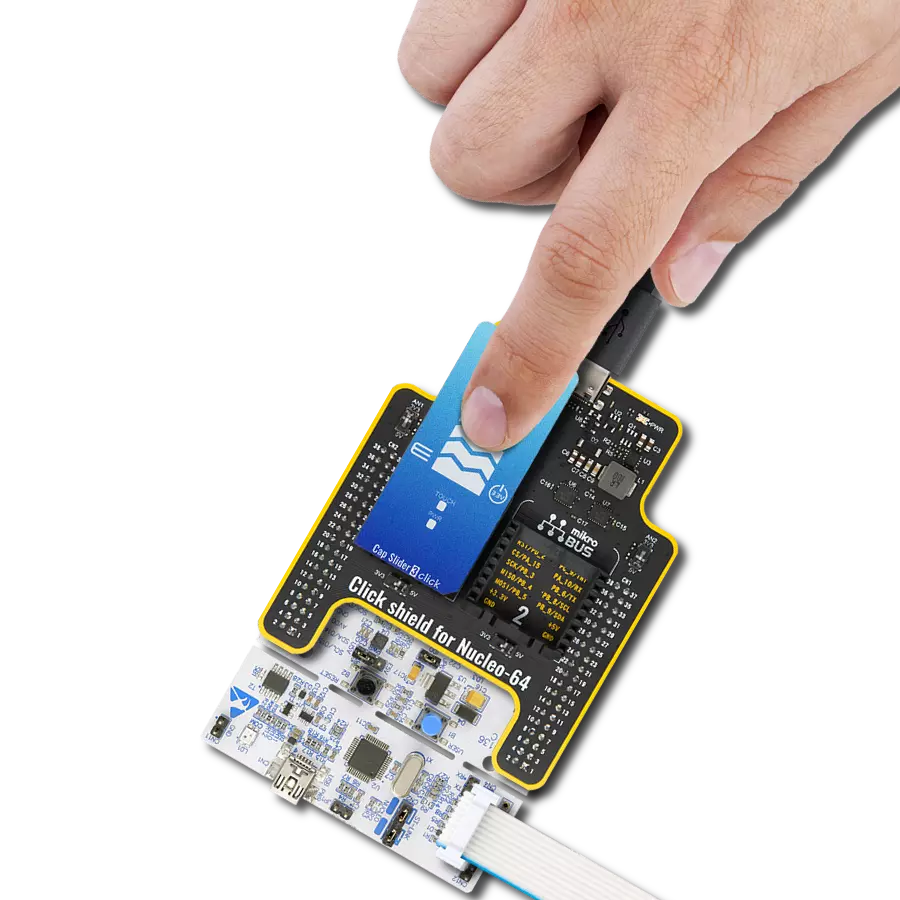

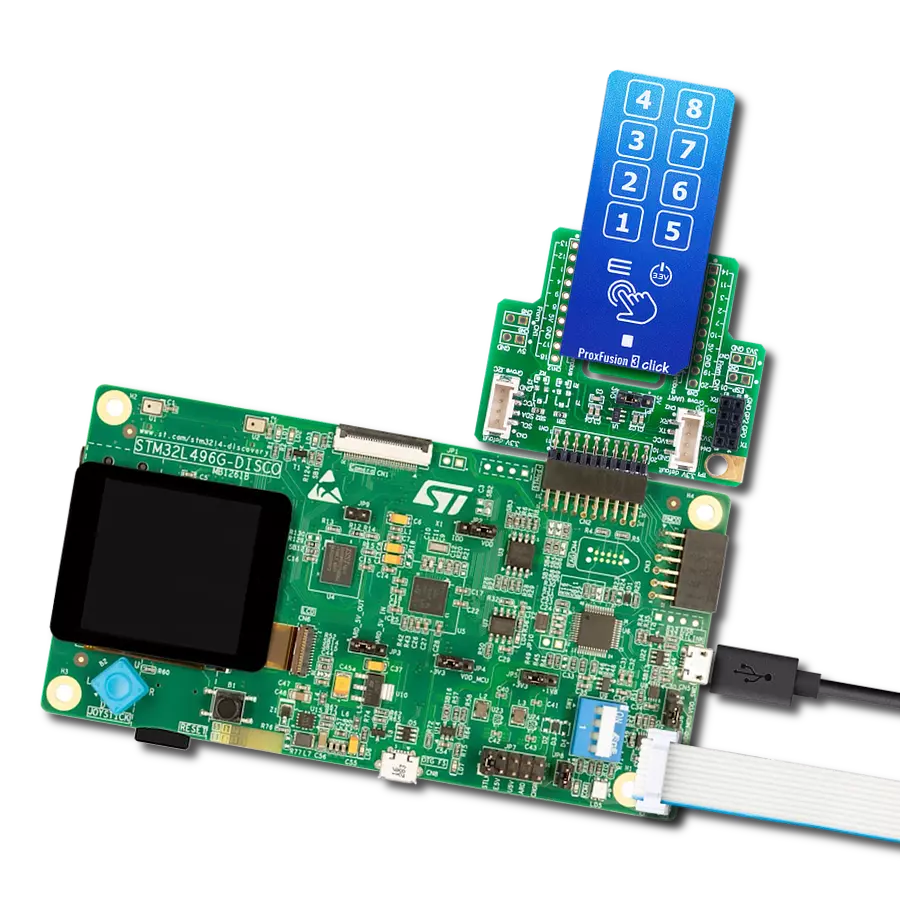

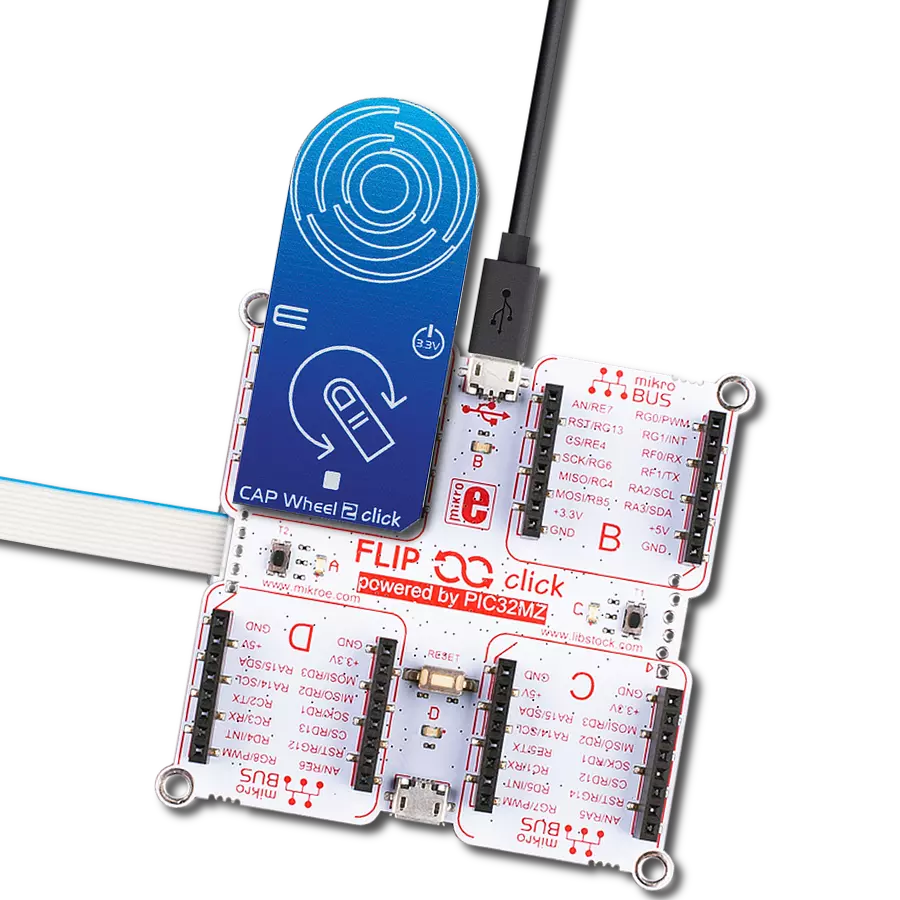

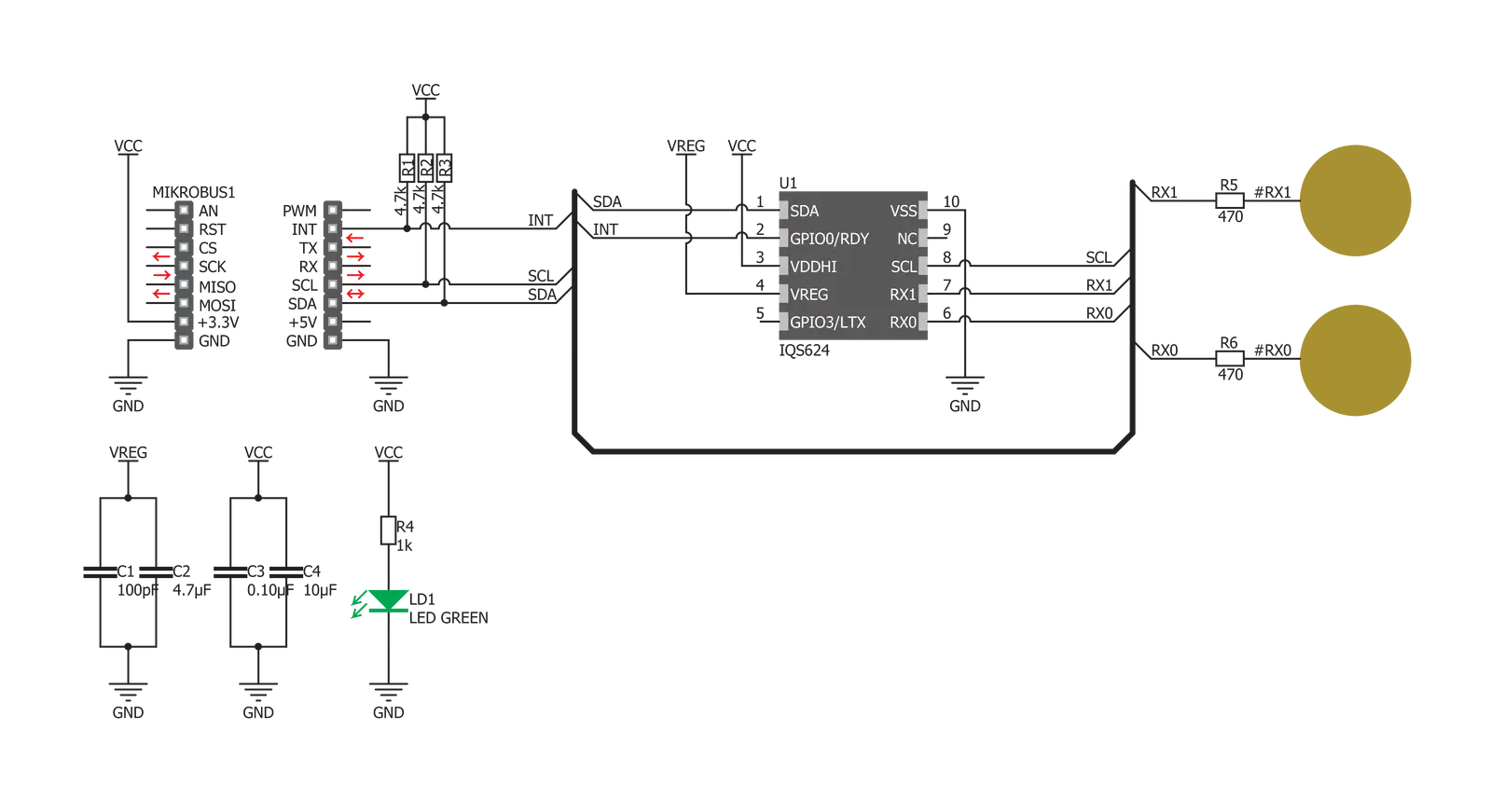

ProxFusion Click is based on the IQS624, a combined multi-sensor IC from Azoteq, including Hall-effect rotation sensing, dual-channel capacitive proximity or touch sensing, or single-channel inductive sensing. This IC features the proven ProxSense® engine, and it has many on-chip features that are used to process the sensor data, such as calculated angle rotation with 1° precision, Automatic Tuning Implementation (ATI), relative rotation angle, and more. All these functions process the sensor data before the final result is sent to the output in a human-understandable format. Besides these processed values, IQS624 can also send raw values on the output so that external processing can be applied. The board's design is reasonably simple since the IC encompasses all the required components on the chip. The I2C bus lines are pulled up to 3.3V with the resistors and the RDY pin from the IC, routed to the INT pin of the mikroBUS™. This pin can report an event when the device is set to work in the event mode via I2C. Otherwise, this pin is

used to indicate a communication window. After the host MCU initializes the communication by sending the valid I2C address of the IQS624 IC, it will respond with the ACK signal, and the RDY pin will be pulled to a LOW logic state to indicate an open communication window. I2C features a time-out that will reset the communication bus and the RDY pin, allowing MCU to use interrupts and break the I2C ACK signal polling loop. The capacitive touch sensing is accomplished by two onboard pads routed to two internal channels of the IQS624 sensor IC. All the calibration can be automatically done by writing to the corresponding ATI registers. This group of registers also contains settings for the capacitive touch threshold and the proximity threshold, as well as some additional general configuration settings for these sensors. Both of these channels can be configured independently. The other four channels of the IQS624 sensor are routed to the outputs of two on-chip Hall plates, which are used to detect a magnetic field rotation. The Hall-effect magnetic field measurement is a

measurement of the current through the Hall-effect sensor plates, generated by the magnetic field penetrating through each plate perpendicularly. Channels 2 and 4 are used to measure positive direction, while channels 3 and 5 are used to measure negative direction. The IC can use the differential data to provide the Hall-effect rotation UI element angle - or a magnet rotation angle, parallel to the click board™ surface. The raw input from the sensors is processed so it outputs comprehensible information at the output. Corresponding registers can be set to configure and receive the data from Hall-effect sensors. The working frequency of the device is 16MHz, and the maximum I2C clock speed is 400kHz. ProxFusion click can work in several different power-saving modes, depending on the design requirements. As explained above, the event mode can be set within the configuration registers. Otherwise, a streaming mode is active by default, and the information can be obtained whenever the RDY is triggered.

Features overview

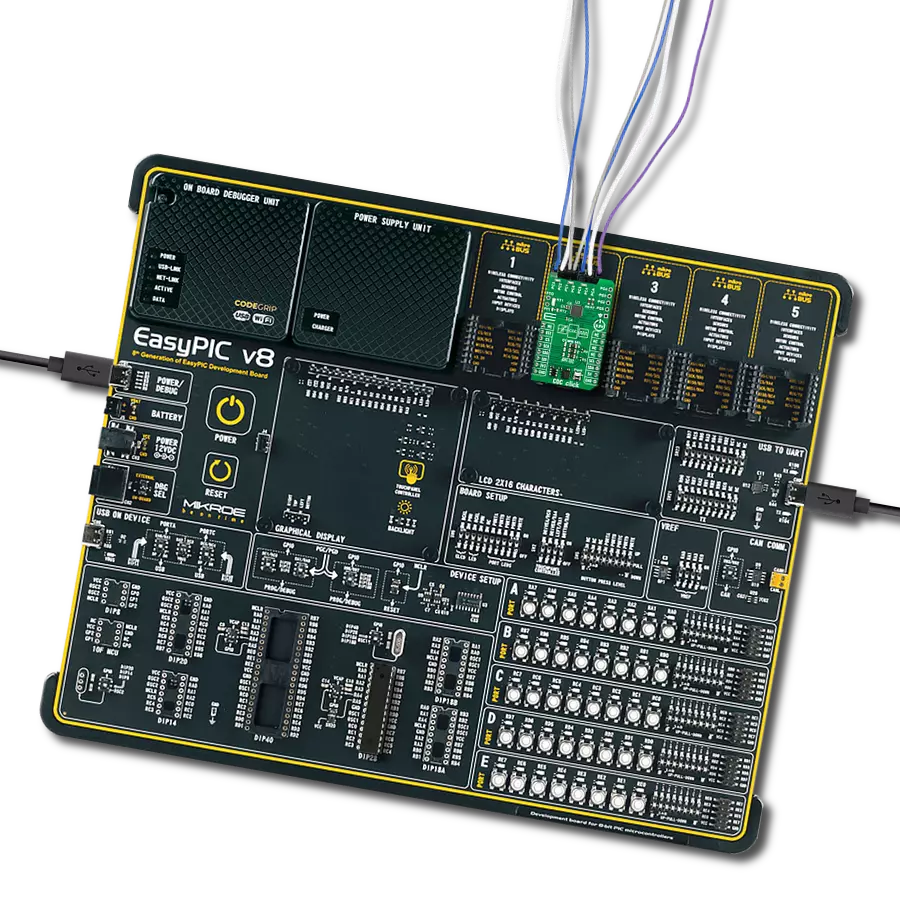

Development board

EasyAVR v7 is the seventh generation of AVR development boards specially designed for the needs of rapid development of embedded applications. It supports a wide range of 16-bit AVR microcontrollers from Microchip and has a broad set of unique functions, such as a powerful onboard mikroProg programmer and In-Circuit debugger over USB. The development board is well organized and designed so that the end-user has all the necessary elements in one place, such as switches, buttons, indicators, connectors, and others. With four different connectors for each port, EasyAVR v7 allows you to connect accessory boards, sensors, and custom electronics more

efficiently than ever. Each part of the EasyAVR v7 development board contains the components necessary for the most efficient operation of the same board. An integrated mikroProg, a fast USB 2.0 programmer with mikroICD hardware In-Circuit Debugger, offers many valuable programming/debugging options and seamless integration with the Mikroe software environment. Besides it also includes a clean and regulated power supply block for the development board. It can use a wide range of external power sources, including an external 12V power supply, 7-12V AC or 9-15V DC via DC connector/screw terminals, and a power source via the USB Type-B (USB-B)

connector. Communication options such as USB-UART and RS-232 are also included, alongside the well-established mikroBUS™ standard, three display options (7-segment, graphical, and character-based LCD), and several different DIP sockets which cover a wide range of 16-bit AVR MCUs. EasyAVR v7 is an integral part of the Mikroe ecosystem for rapid development. Natively supported by Mikroe software tools, it covers many aspects of prototyping and development thanks to a considerable number of different Click boards™ (over a thousand boards), the number of which is growing every day.

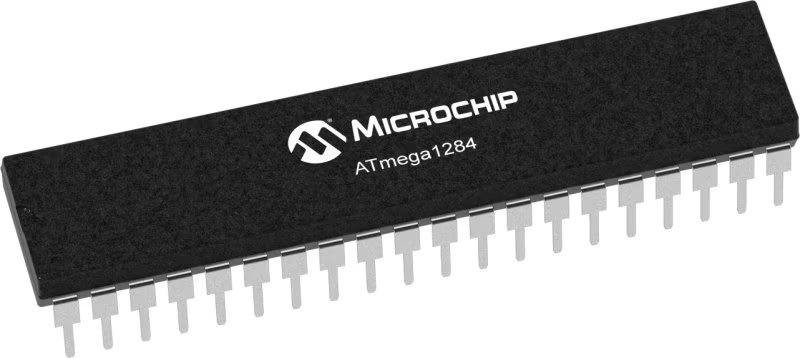

Microcontroller Overview

MCU Card / MCU

Architecture

AVR

MCU Memory (KB)

128

Silicon Vendor

Microchip

Pin count

40

RAM (Bytes)

16384

Used MCU Pins

mikroBUS™ mapper

Take a closer look

Click board™ Schematic

Step by step

Project assembly

Software Support

Library Description

This library contains API for ProxFusion Click driver.

Key functions:

proxfusion_get_touch- This function detects touch eventproxfusion_set_system_reg- This function sets system registerproxfusion_set_event_reg- This function select events

Open Source

Code example

The complete application code and a ready-to-use project are available through the NECTO Studio Package Manager for direct installation in the NECTO Studio. The application code can also be found on the MIKROE GitHub account.

/*!

* \file

* \brief ProxFusion Click example

*

* # Description

* This demo-app reads and displays touch events using ProxFusion Click.

*

* The demo application is composed of two sections :

*

* ## Application Init

* Configuring Clicks and log objects.

* Settings the Click in the default configuration.

*

* ## Application Task

* Checks if a new touch event occurred and prints(logs) event message on usbuart.

*

* \author Katarina Perendic

*

*/

// ------------------------------------------------------------------- INCLUDES

#include "board.h"

#include "log.h"

#include "proxfusion.h"

// ------------------------------------------------------------------ VARIABLES

static proxfusion_t proxfusion;

static log_t logger;

// ------------------------------------------------------ APPLICATION FUNCTIONS

void application_init ( void )

{

log_cfg_t log_cfg; /**< Logger config object. */

proxfusion_cfg_t proxfusion_cfg; /**< Click config object. */

/**

* Logger initialization.

* Default baud rate: 115200

* Default log level: LOG_LEVEL_DEBUG

* @note If USB_UART_RX and USB_UART_TX

* are defined as HAL_PIN_NC, you will

* need to define them manually for log to work.

* See @b LOG_MAP_USB_UART macro definition for detailed explanation.

*/

LOG_MAP_USB_UART( log_cfg );

log_init( &logger, &log_cfg );

log_info( &logger, " Application Init " );

// Click initialization.

proxfusion_cfg_setup( &proxfusion_cfg );

PROXFUSION_MAP_MIKROBUS( proxfusion_cfg, MIKROBUS_1 );

if ( I2C_MASTER_ERROR == proxfusion_init( &proxfusion, &proxfusion_cfg ) )

{

log_error( &logger, " Communication init." );

for ( ; ; );

}

if ( PROXFUSION_ERROR == proxfusion_default_cfg ( &proxfusion ) )

{

log_error( &logger, " Default configuration." );

for ( ; ; );

}

log_info( &logger, " Application Task " );

}

void application_task ( void )

{

uint8_t touch = proxfusion_get_touch( &proxfusion );

if ( 1 == touch )

{

log_printf( &logger, " Touch button 1 is pressed\r\n" );

}

else if ( 2 == touch )

{

log_printf( &logger, " Touch button 2 is pressed\r\n" );

}

else if ( 3 == touch )

{

log_printf( &logger, " Both touch buttons are pressed\r\n" );

}

Delay_ms ( 100 );

}

int main ( void )

{

/* Do not remove this line or clock might not be set correctly. */

#ifdef PREINIT_SUPPORTED

preinit();

#endif

application_init( );

for ( ; ; )

{

application_task( );

}

return 0;

}

// ------------------------------------------------------------------------ END