Discover how our magnetometer solution empowers industries and scientists to navigate the complex world of magnetism with unparalleled accuracy

A

A

Hardware Overview

How does it work?

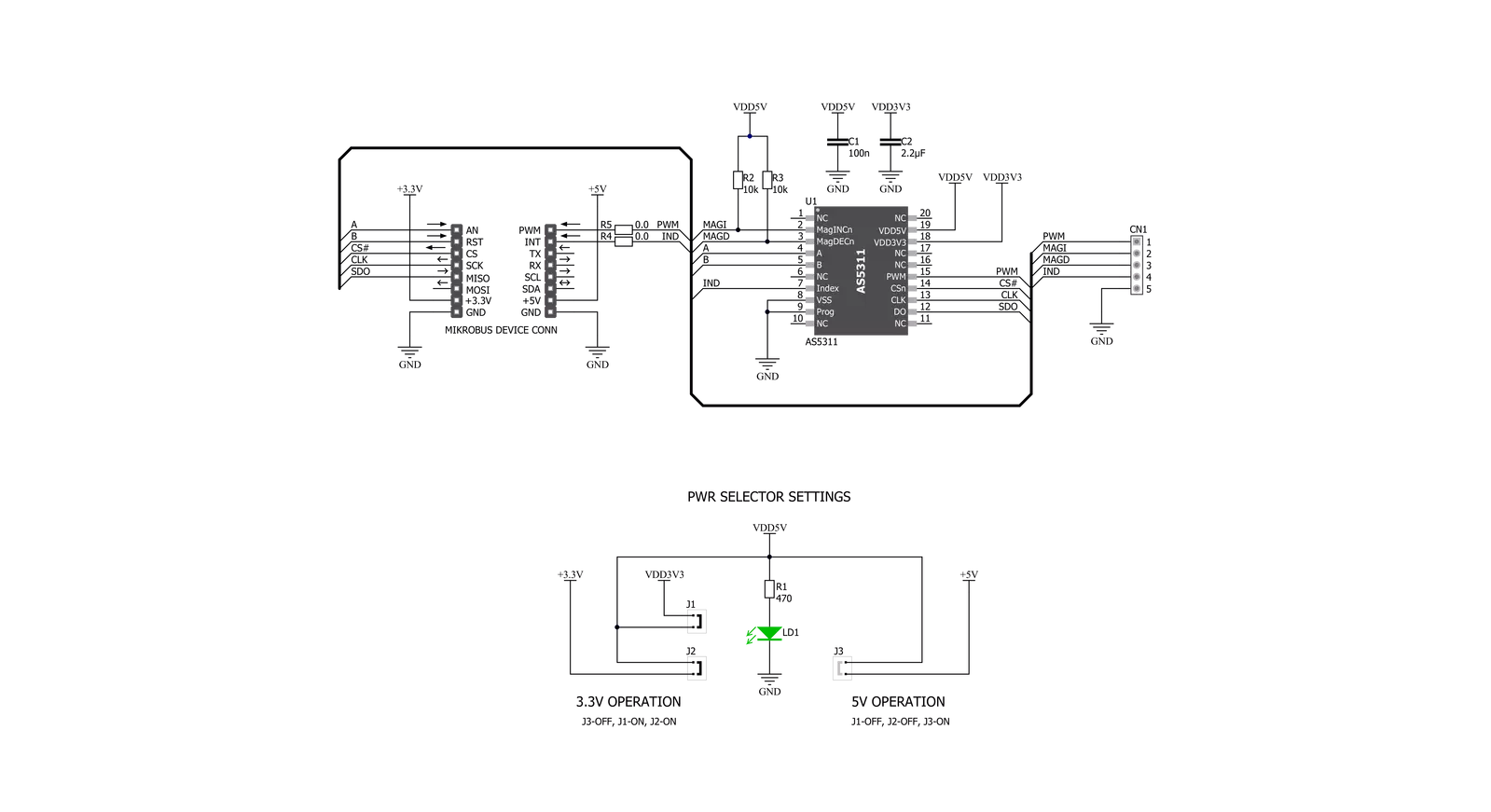

Magneto 4 Click is based on the AS5311, a high resolution magnetic linear encoder from ams OSRAM which integrates Hall elements, a low-noise analog front-end, and a digital signal processing (DSP), on the same die. It is a System-on-Chip used for performing highly accurate measurements. It is designed to be used along with a multi-pole magnetic strip or ring. A pole length should be 1.0mm, while the strip should be placed about 3mm above the IC surface. The magnetic strip movement is translated into a 12-bit word on the output. In other words, the output is cycled from 0 to 4095 for each 2mm the strip moves. Also, this means that the movement resolution goes down to 488nm per LSB. The AS5311 can output the movement data in several different formats: it can either output the bit-string over the serial interface, or by using the 12-bit pulse-width modulated signal (PWM). The pulse width of the PWM signal starts with 1µs and is increased for every 0.488μm. The maximum pulse width is 4095µs, which corresponds to a magnet movement of 2mm. The incremental outputs allow this Click board™ to be used in place of a mechanical or optical quadrature encoder. These two outputs are phase-shifted for 90 degrees: the output A leads output B when the magnet is moving from right to left and vice-versa:

output B leads output A when the magnet is moving from left to right. The resolution of the incremental outputs is 10 bits per pole pair (1024 steps), which results in a step length of 1.95μm. An additional index pin is triggered for each pulse pair. These pins can be disabled by using the Chip Select (CS) pin: whenever the CS pin is at a HIGH logic level, all the incremental output pins (A, B, Index) are disabled (fixed at a HIGH logic state). To prevent flickering in border-conditions, there is a hysteresis of 2 LSBs implemented. The serial interface is very similar to SPI. However, depending on the correlation between the Chip Select pin and the clock signal logic state, two data modes are available: if the CS pin is pulled to a HIGH logic state (or floating) during the clock HIGH pulse, the AS5311 will report the magnitude (strength) of the magnetic field. Else, it will output the absolute linear position data. The output data contains both the magnetic/positional data bits (11 bits) and status bits (5 bits). The status report includes offset compensation status, "CORDIC" overflow status, linearity alarm status, and two magnetic field strength status bits. The AS5311 can use either two hardware pins (MagINCn, MagENCn) routed to the additional header, or two status bits within the status report. These two bits/pins are used to describe the magnitude of

the magnetic field. The datasheet refers to three different magnetic field magnitudes: green, yellow, and red. The green status represents the optimal strength of the magnetic field. The yellow status indicated that the obtained data may not be accurate, while the red status indicates that the magnetic field generated by the multi-pole strip or ring is weak and it is not recommended to use it. For proper operation of the Click board™, a multi-pole magnetic strip should be properly placed above the IC so that it can move along x-axis only. To support correct placing, the Click board™ comes with four holes, which can be used to accurately position the strip in place. Please refer to the datasheet for more details about the magnetic strip positioning. The Click board™ can work with MCUs that use with both 3.3V and 5V supply voltages. The power supply selection on this click is a bit specific: to select 3.3V, both SMD jumpers grouped under the 3.3V label should be populated, while the SMD jumper under the 5V label should not be populated. Selecting 5V is done by removing two SMD jumpers under the 3.3V label and populating one SMD jumper under the 5V label. Please note that populating all the SMD jumpers at once may lead to malfunction.

Features overview

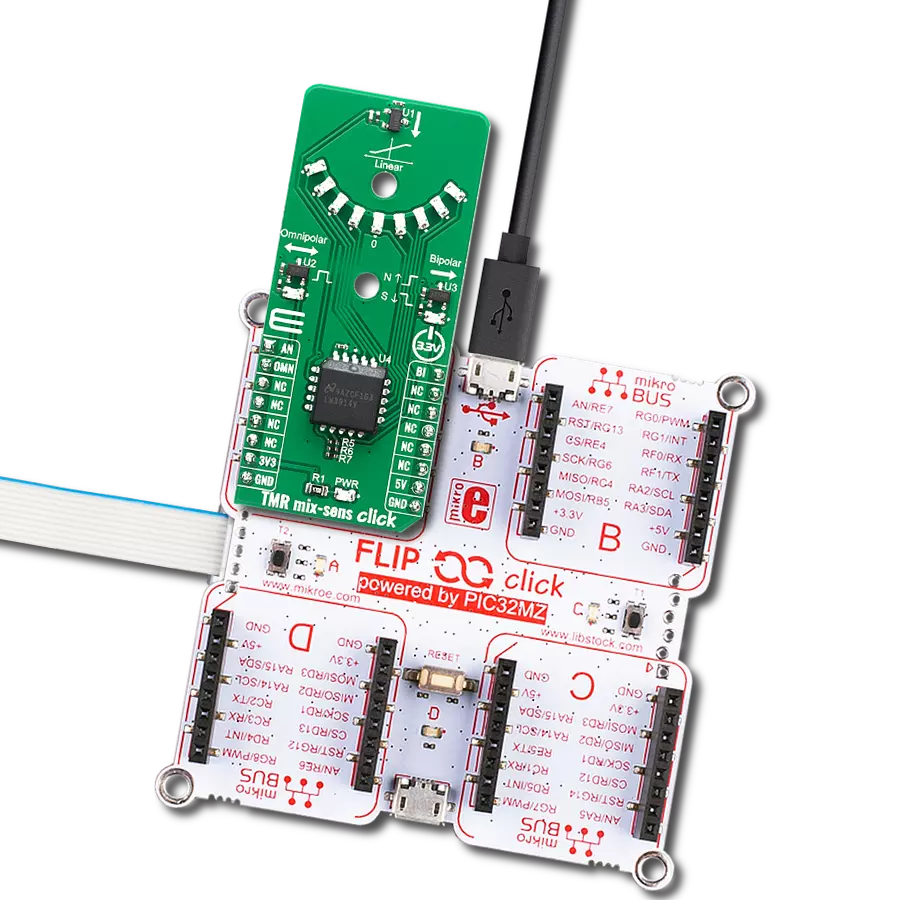

Development board

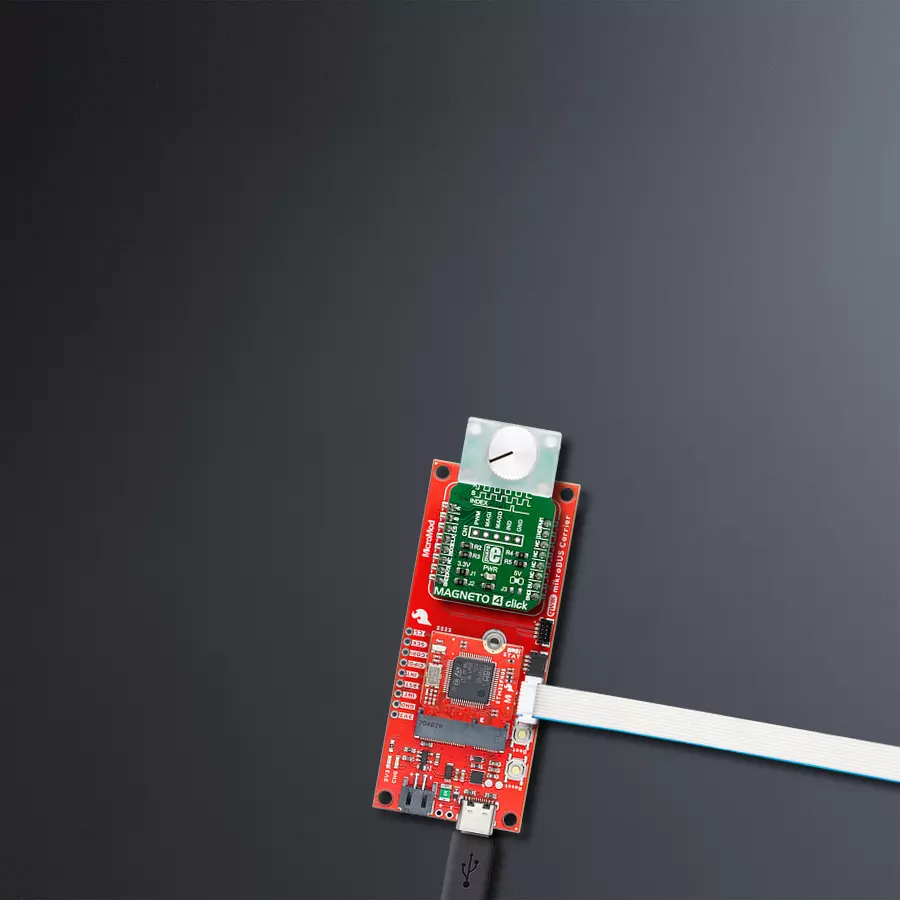

SparkFun MicroMod mikroBUS Carrier board takes advantage of the MicroMod, Qwiic, and mikroBUS™ ecosystems making it easy to prototype with each combined rapidly. The MicroMod M.2 socket and mikroBUS™ 8-pin header allow users to experiment with any processor board in the MicroMod ecosystem and any Click board™ in the mikroBUS™ ecosystem,

respectively. This board also features two Qwiic connectors to seamlessly integrate hundreds of Qwiic sensors and accessories into your project. The mikroBUS™ socket comprises a pair of 8-pin female headers with a standardized pin configuration. The pins consist of three groups of communications pins (SPI, UART, and I2C), six additional pins (PWM, Interrupt, Analog input,

Reset, and Chip select), and two power groups (3.3V and 5V). While a modern USB-C connector makes programming easy, the Carrier Board is also equipped with an MCP73831 single-cell Lithium-Ion/Lithium-Polymer charge IC so you can charge an attached single-cell Li-Po battery. The charge IC receives power from the USB connection and can source up to 450mA to charge an attached battery.

Microcontroller Overview

MCU Card / MCU

Architecture

ARM Cortex-M4

MCU Memory (KB)

1024

Silicon Vendor

STMicroelectronics

Pin count

64

RAM (Bytes)

196608

You complete me!

Accessories

Rotary Magnetic Holder is an addition designed for use alongside a magnetic rotary position sensor. It comes with a plastic stand measuring 22x16x10 millimeters (L x W x H), as well as an adjustable shaft with a 6mm diameter magnet. The plastic frame has four round feet that fit into holes in the board near the magnetic rotary position sensor, with a 6mm diameter hole on top to match the adjustable shaft that carries the magnet. This shaft has a height adjustment screw on it, allowing the user to adjust it between 18 and 22 millimeters. This way, fast prototyping and quick measurements of the magnet characteristics are allowed during development.

Used MCU Pins

mikroBUS™ mapper

Take a closer look

Click board™ Schematic

Step by step

Project assembly

Track your results in real time

Application Output

1. Application Output - In Debug mode, the 'Application Output' window enables real-time data monitoring, offering direct insight into execution results. Ensure proper data display by configuring the environment correctly using the provided tutorial.

2. UART Terminal - Use the UART Terminal to monitor data transmission via a USB to UART converter, allowing direct communication between the Click board™ and your development system. Configure the baud rate and other serial settings according to your project's requirements to ensure proper functionality. For step-by-step setup instructions, refer to the provided tutorial.

3. Plot Output - The Plot feature offers a powerful way to visualize real-time sensor data, enabling trend analysis, debugging, and comparison of multiple data points. To set it up correctly, follow the provided tutorial, which includes a step-by-step example of using the Plot feature to display Click board™ readings. To use the Plot feature in your code, use the function: plot(*insert_graph_name*, variable_name);. This is a general format, and it is up to the user to replace 'insert_graph_name' with the actual graph name and 'variable_name' with the parameter to be displayed.

Software Support

Library Description

This library contains API for Magneto 4 Click driver.

Key functions:

magneto4_get_magnetic_status- Get Magnetic measurement statusmagneto4_get_encoder_position- Encoder positionmagneto4_get_encoder_direction- Encoder direction

Open Source

Code example

The complete application code and a ready-to-use project are available through the NECTO Studio Package Manager for direct installation in the NECTO Studio. The application code can also be found on the MIKROE GitHub account.

/*!

* \file

* \brief Magneto4 Click example

*

* # Description

* Reads and logs magnetic field strength values

* if magnetic field strength values bigger than 3000,

* start magnetic linear position mode,

* when moving the sensor from left to right the position for 1 step is reduced.

*

* The demo application is composed of two sections :

*

* ## Application Init

* Initializes Driver init and sets start encoder position on the zero.

* Reads and logs magnetic field strength values.

* For starting an encoder, it is necessary that the magnetic field strength

* is greater than 3000.

*

* ## Application Task

* When moving the sensor from left to right, one step is added

* and when moving from right to left, the position for 1 step is reduced.

*

* \author Luka Filipovic

*

*/

// ------------------------------------------------------------------- INCLUDES

#include "board.h"

#include "log.h"

#include "magneto4.h"

// ------------------------------------------------------------------ VARIABLES

static magneto4_t magneto4;

static log_t logger;

static int32_t enc_position;

static int32_t old_position = 255;

static int16_t magnetic_field = 0;

// ------------------------------------------------------ APPLICATION FUNCTIONS

void application_init ( void )

{

log_cfg_t log_cfg;

magneto4_cfg_t cfg;

/**

* Logger initialization.

* Default baud rate: 115200

* Default log level: LOG_LEVEL_DEBUG

* @note If USB_UART_RX and USB_UART_TX

* are defined as HAL_PIN_NC, you will

* need to define them manually for log to work.

* See @b LOG_MAP_USB_UART macro definition for detailed explanation.

*/

LOG_MAP_USB_UART( log_cfg );

log_init( &logger, &log_cfg );

log_info( &logger, "---- Application Init ----" );

// Click initialization.

magneto4_cfg_setup( &cfg );

MAGNETO4_MAP_MIKROBUS( cfg, MIKROBUS_1 );

magneto4_init( &magneto4, &cfg );

magneto4_default_cfg ( &magneto4 );

log_printf( &logger, " --- Please, bring the magnet close ---\r\n" );

while ( magnetic_field < MAGNETO4_MAX_MAGNETIC_FIELD_VALUE )

{

magnetic_field = magneto4_get_magnetic_field( &magneto4 );

log_printf( &logger, " Magnetic field strength : %d\r\n", magnetic_field );

Delay_ms ( 1000 );

}

Delay_ms ( 1000 );

Delay_ms ( 500 );

log_printf( &logger, " --- Magnetic Linear Position ---\r\n" );

}

void application_task ( void )

{

// Task implementation.

magneto4_get_encoder_position( &magneto4 );

enc_position = magneto4.encoder_position;

if ( old_position != enc_position )

{

log_printf( &logger, " Encoder position : %d\r\n", enc_position );

log_printf( &logger, " ------------------------\r\n" );

}

old_position = enc_position;

}

int main ( void )

{

/* Do not remove this line or clock might not be set correctly. */

#ifdef PREINIT_SUPPORTED

preinit();

#endif

application_init( );

for ( ; ; )

{

application_task( );

}

return 0;

}

// ------------------------------------------------------------------------ END

Additional Support

Resources

Category:Magnetic