Detect the distance of an object, regardless of its color and reflectance

A

A

Hardware Overview

How does it work?

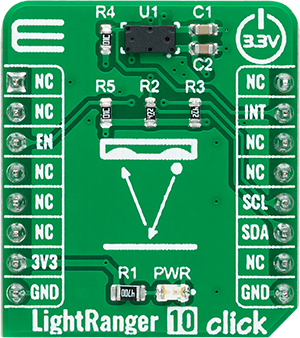

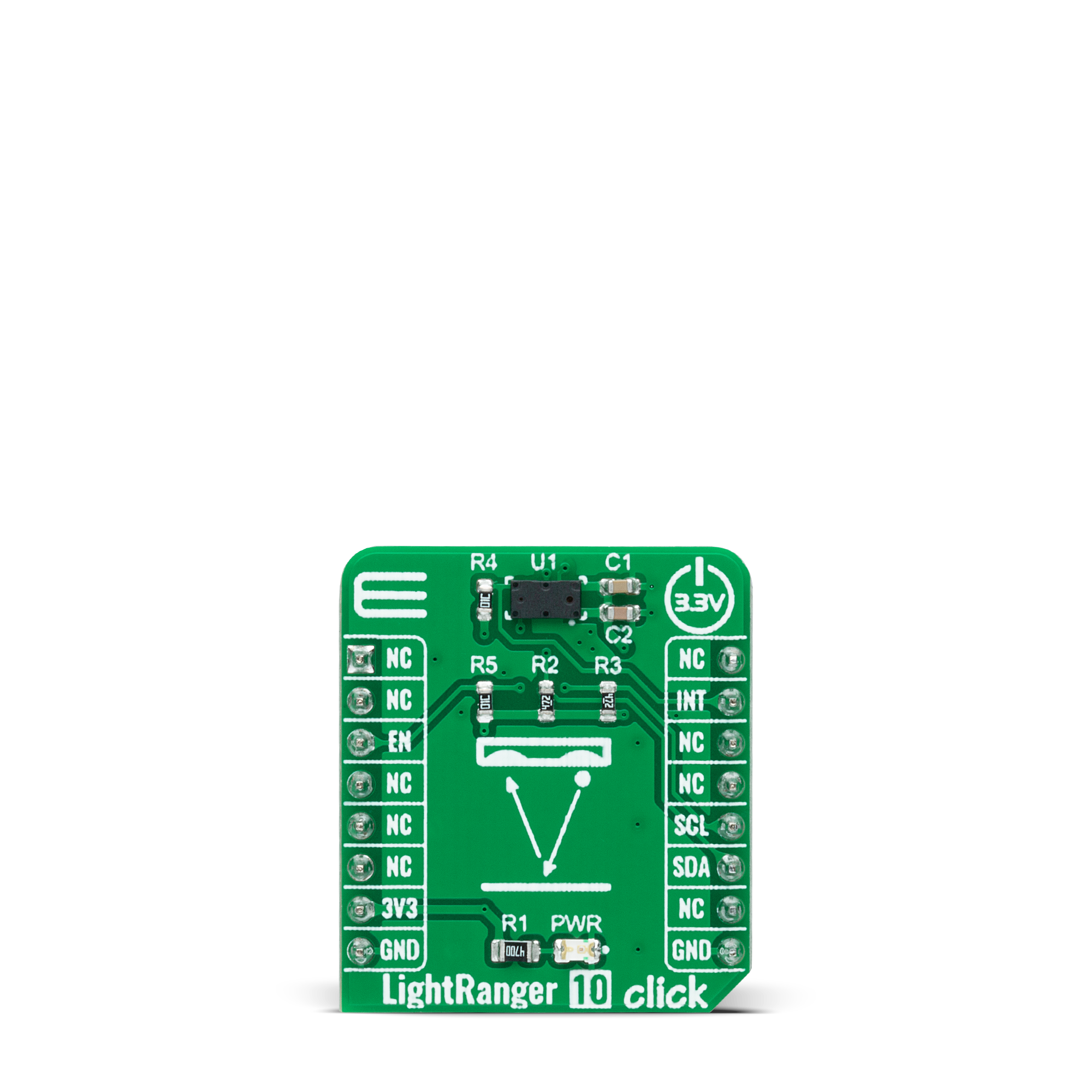

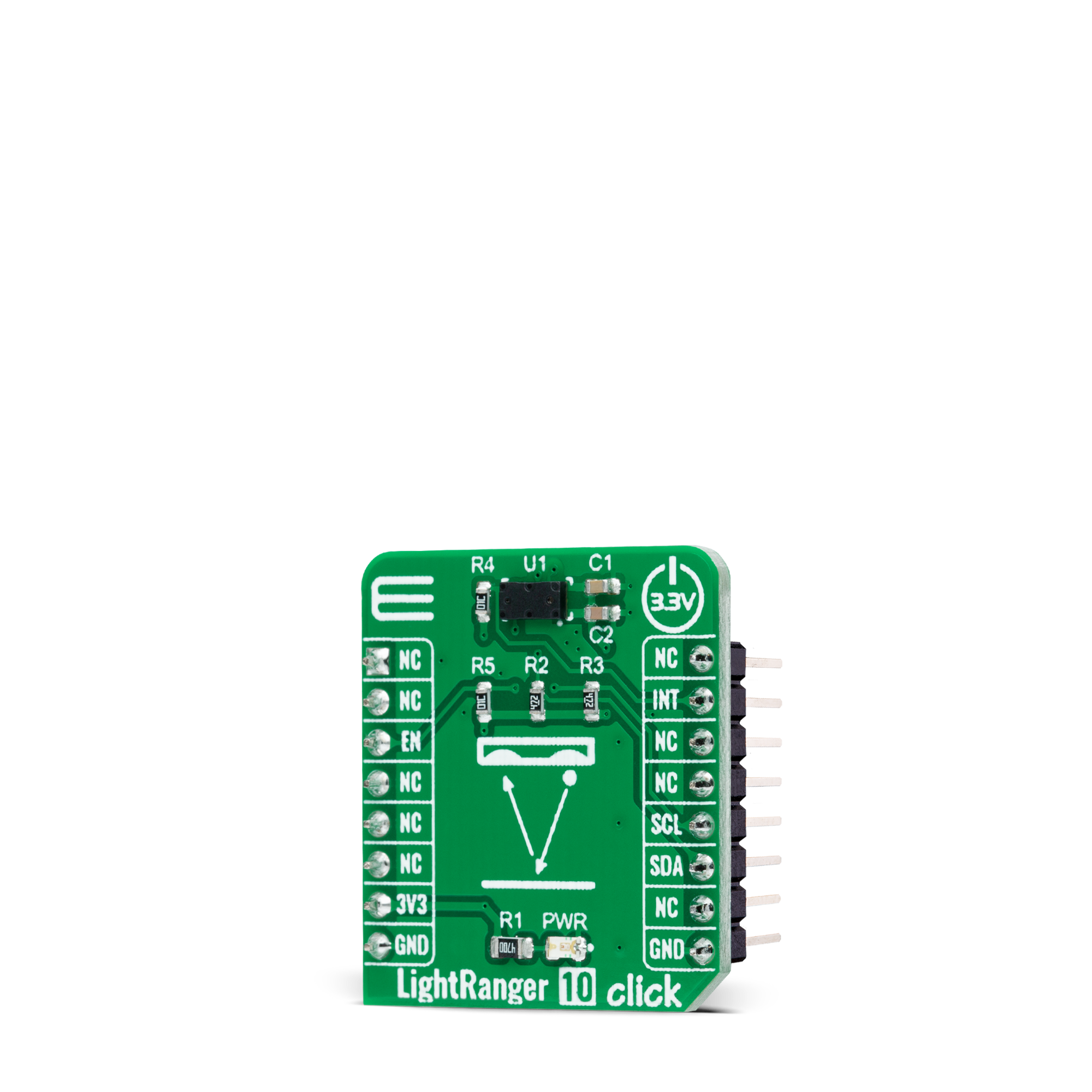

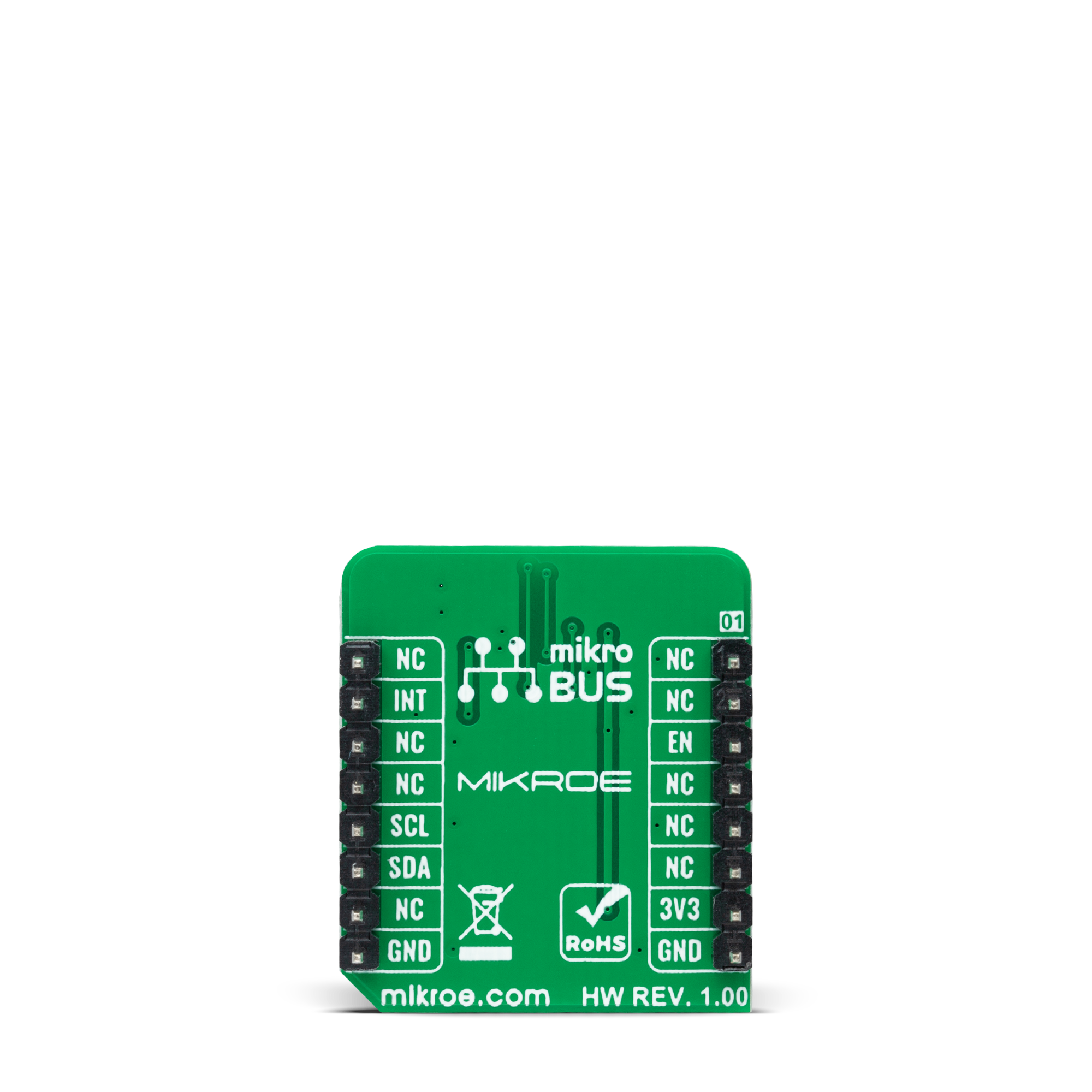

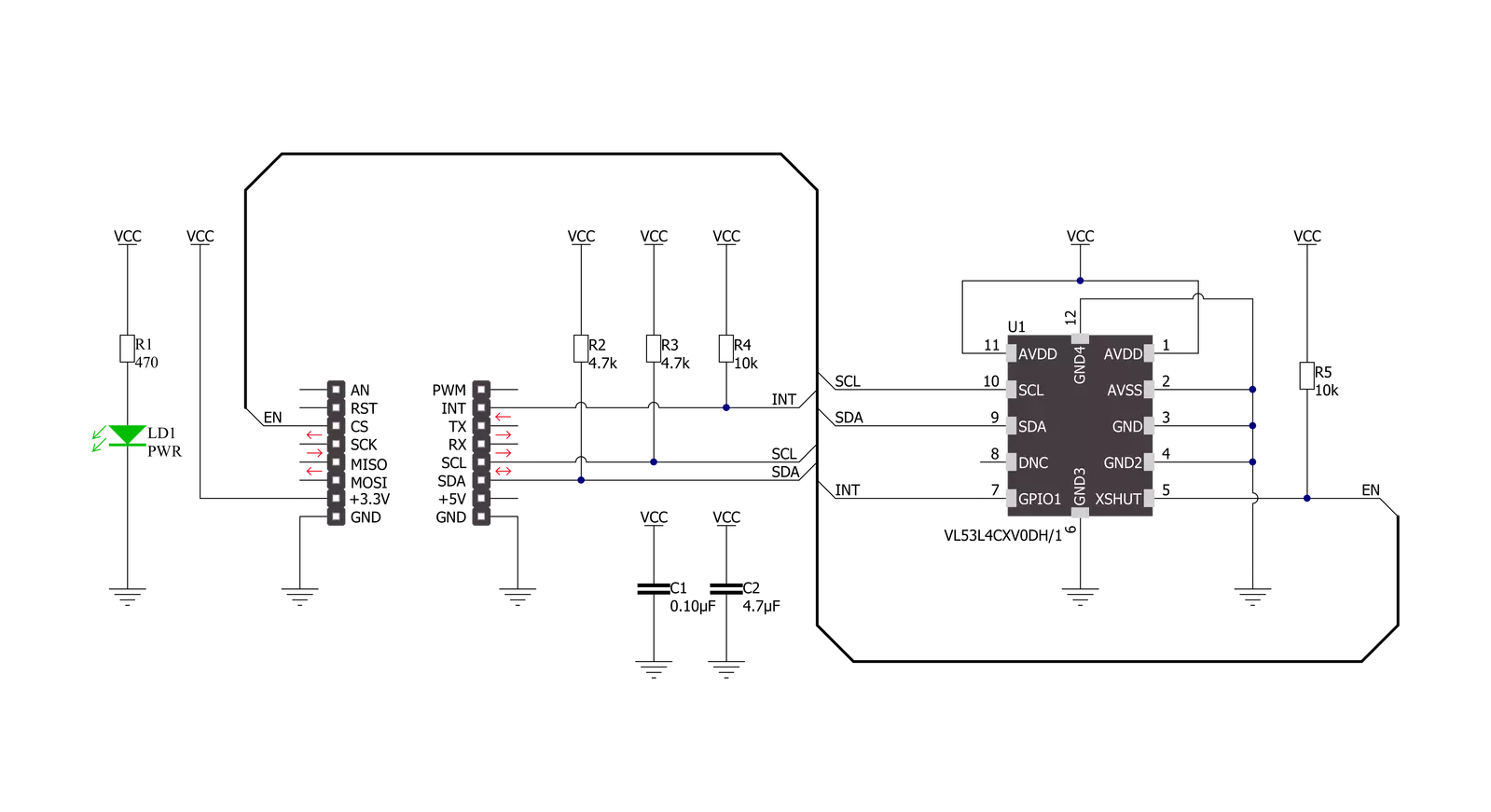

LightRanger 10 Click is based on the VL53L4CX, a ToF (Time-of-Flight) optical distance sensor with an extended target detection range from STMicroelectronics. This ToF sensor integrates a VCSEL (vertical-cavity surface-emitting laser), emitting an entirely invisible 940nm IR light, which is totally safe for eyes (Class 1 certification). Also, there is a SPAD (single-photon avalanche diode) array which helps the VL53L4CX to achieve the best-ranging performance even when a Click board™ is hidden behind a wide range of cover glass materials. Specifically designed for long-range and multi-target measurements, the VL53L4CX provides accurate distance measurements up to 6m with excellent results over short distances and 18° FoV (Field

of View), improving performances under ambient light. Thanks to ST's patented algorithms, the VL53L4CX can detect multiple objects within the FoV with depth understanding. ST histogram algorithms ensure cover glass crosstalk immunity beyond 80cm and dynamic smudge compensation for targets below 80cm. Like all Time-of-Flight sensors based on ST's FlightSense technology, the VL53L4CX records an absolute distance measurement regardless of the target color and reflectance. LightRanger 10 Click communicates with MCU using the standard I2C 2-Wire interface to read data and configure settings with a maximum clock frequency of 1MHz. This Click board™ can be enabled or disabled using the EN pin of the mikroBUS™ socket, hence, offering a switch

operation to turn ON the initial boot sequence of the VL53L4CX. It also possesses an additional interrupt pin, routed to the INT pin on the mikroBUS™ socket, indicating when a ranging measurement is available. This Click board™ can only be operated from a 3.3V logic voltage level. Therefore, the board must perform appropriate logic voltage conversion before using MCUs with different logic levels. However, the Click board™ comes equipped with a library containing functions and an example code that can be used as a reference for further development.

Features overview

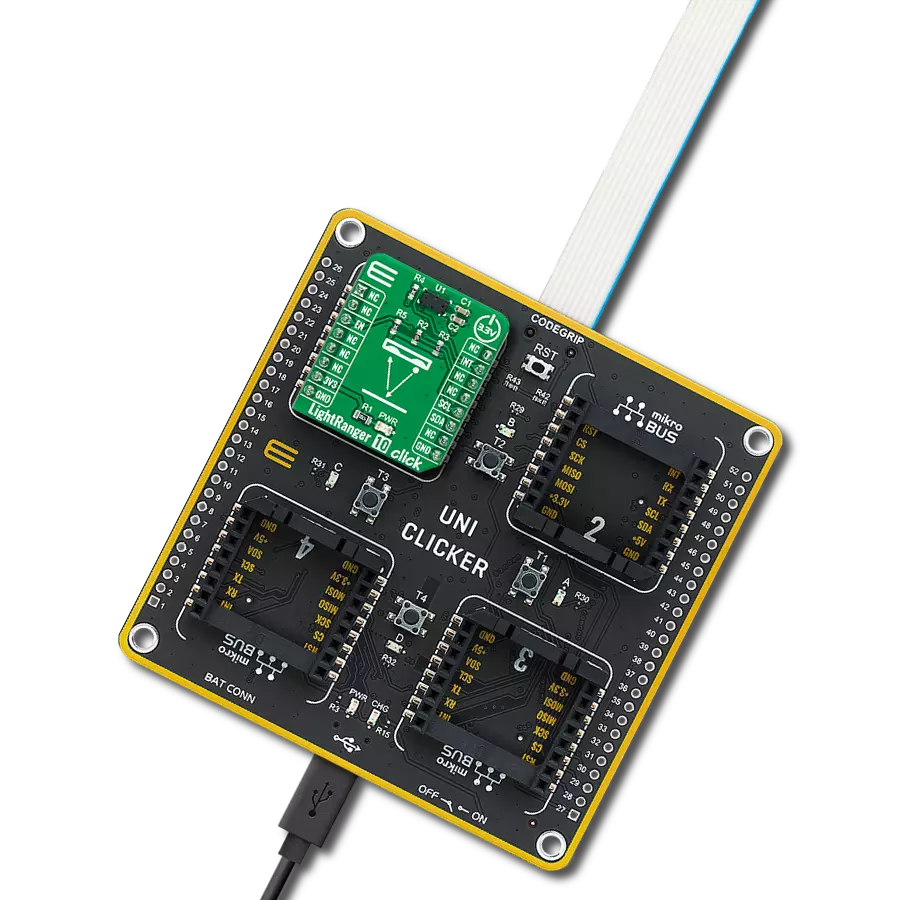

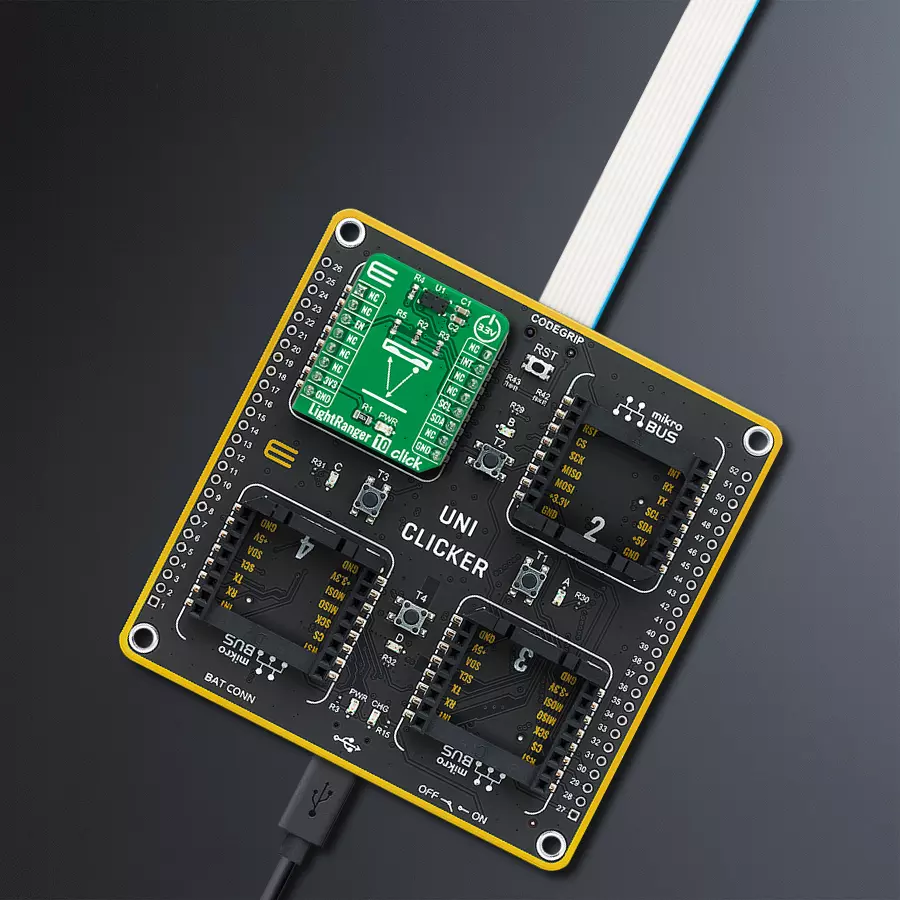

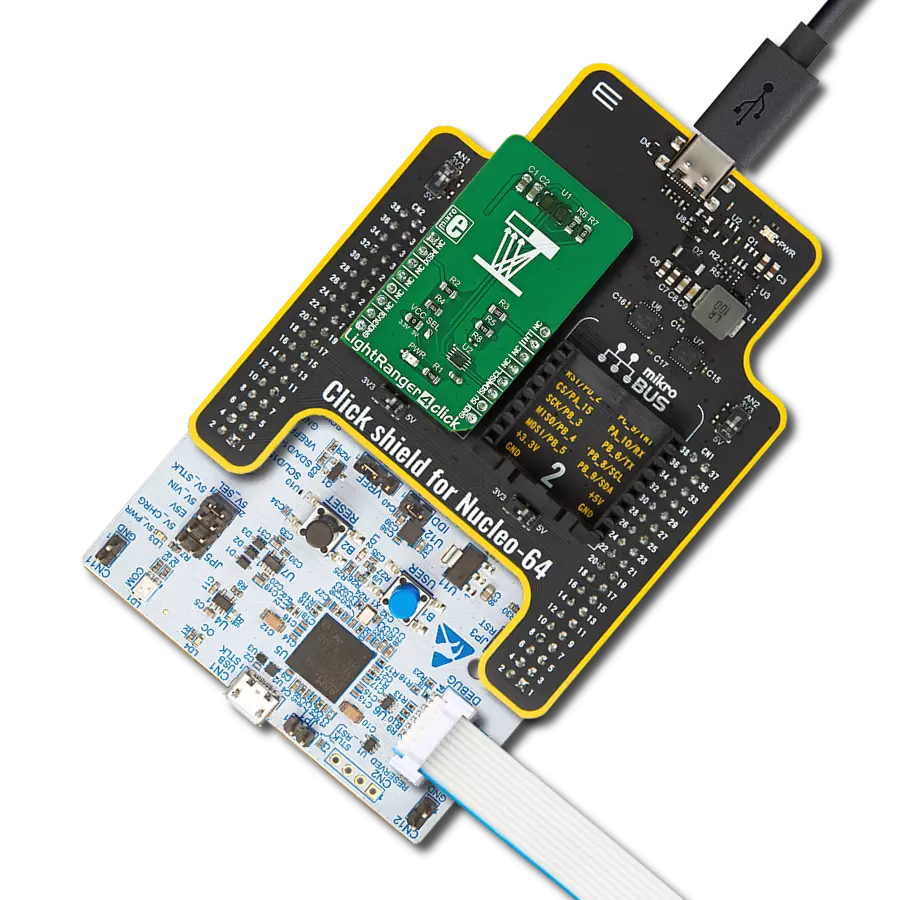

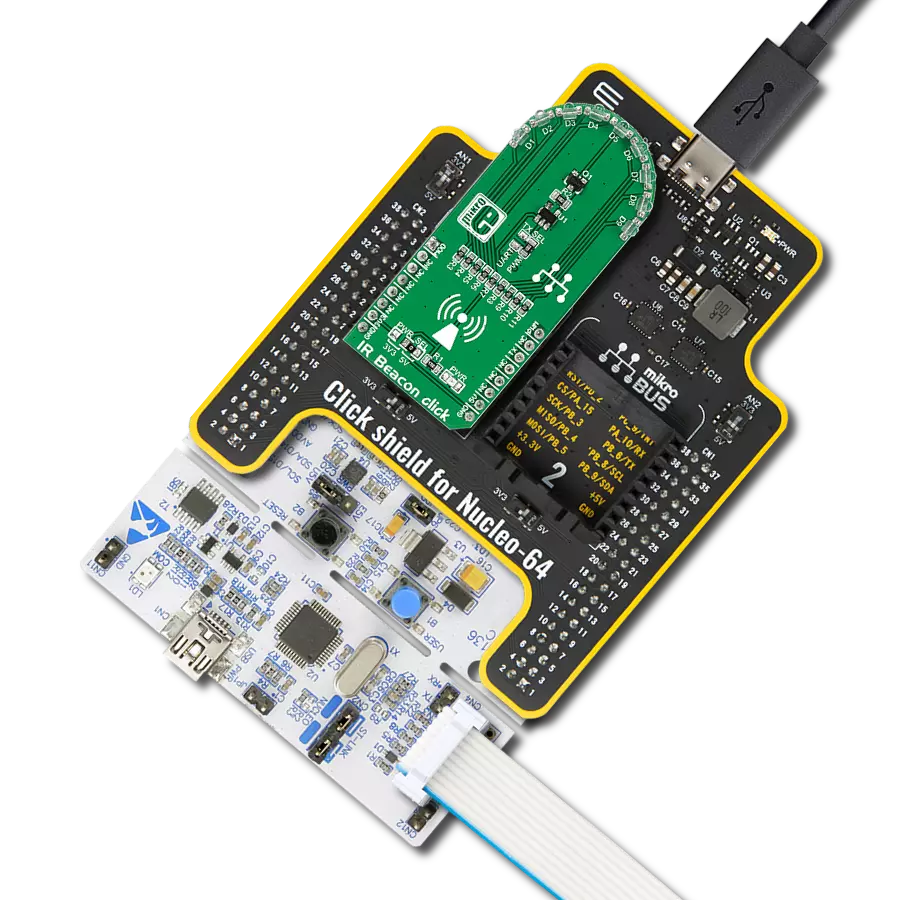

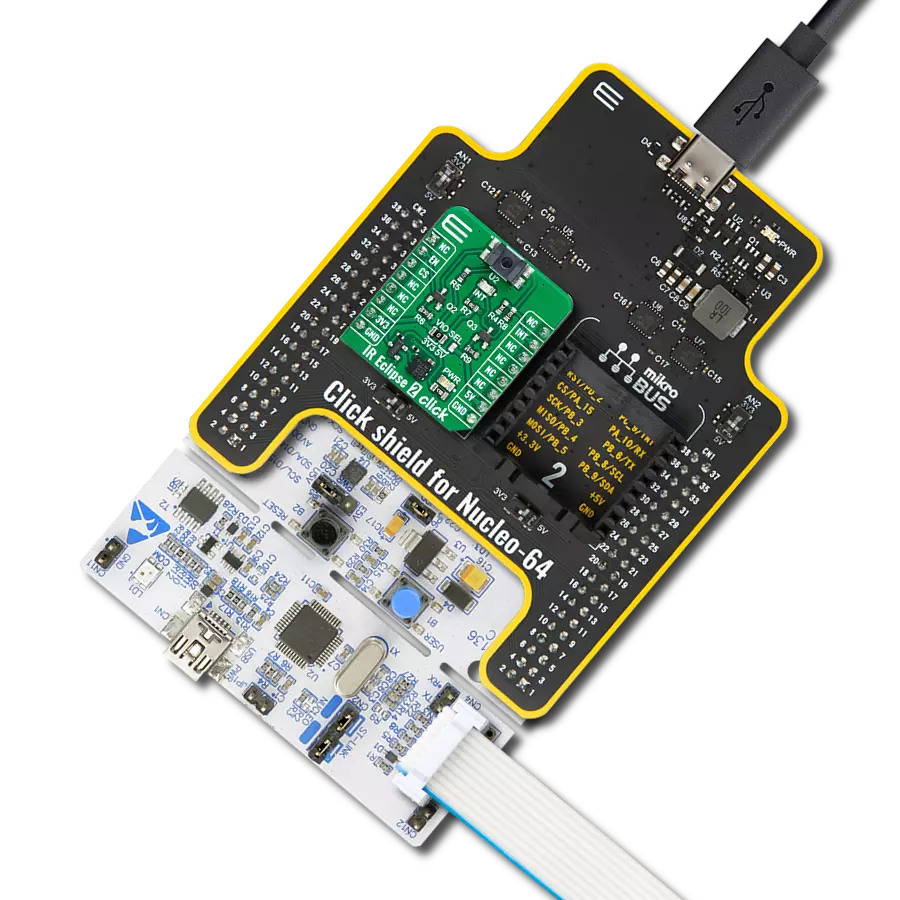

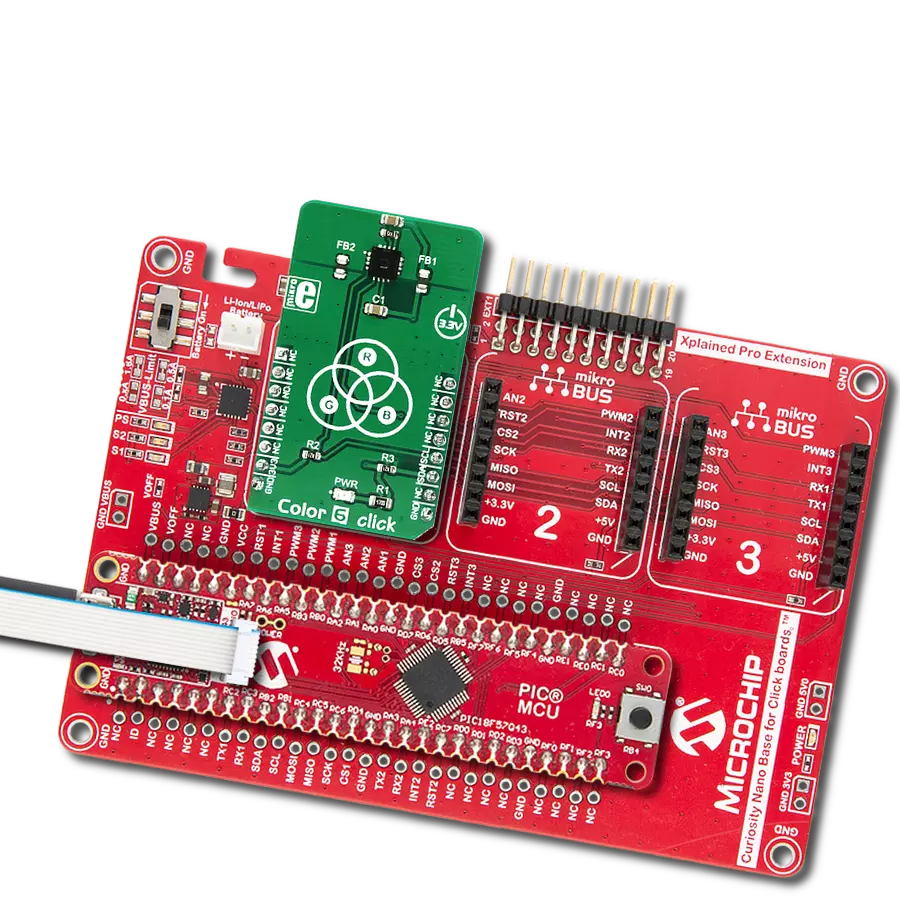

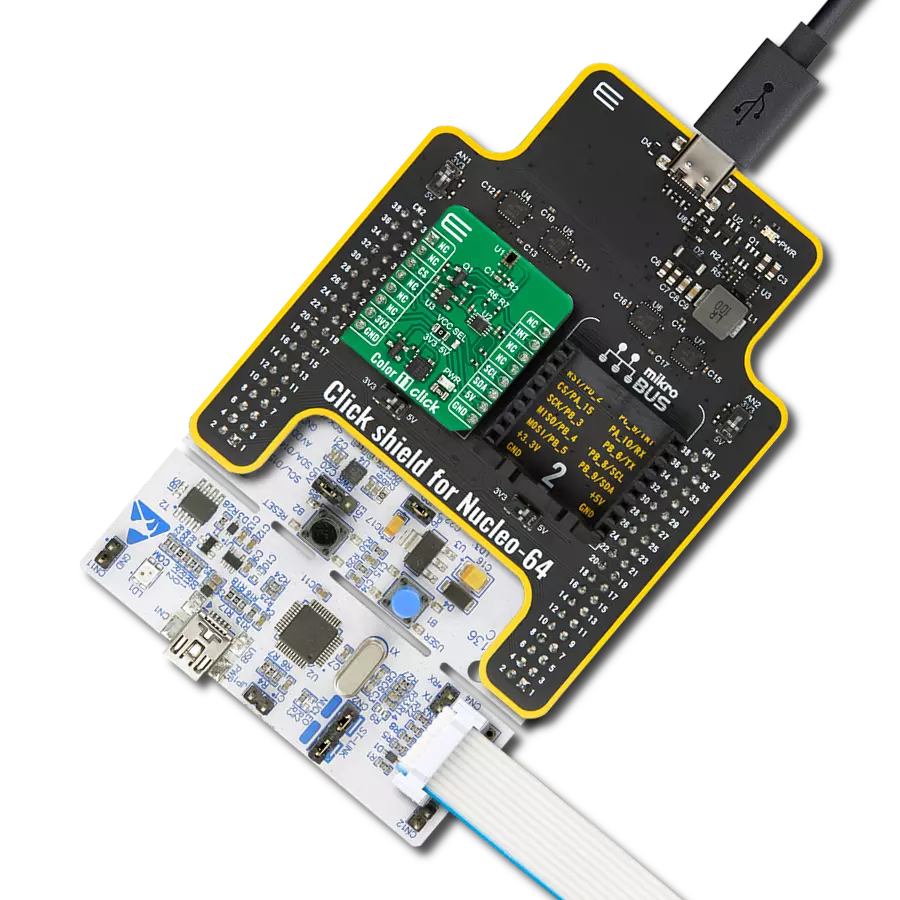

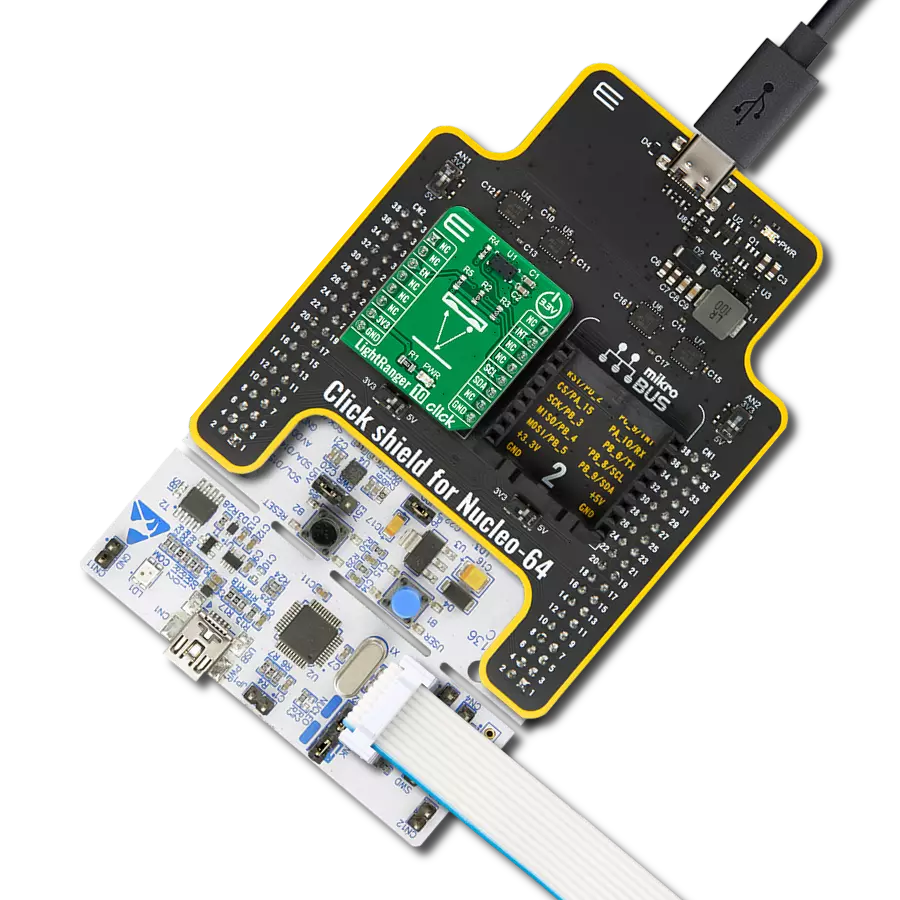

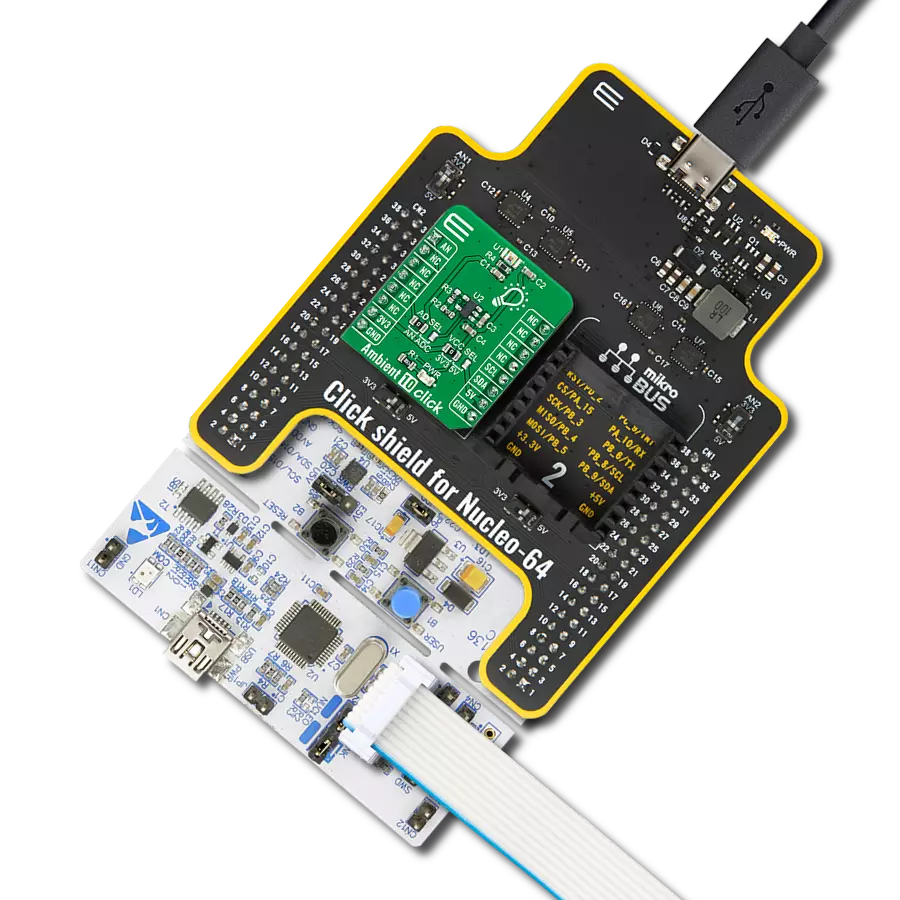

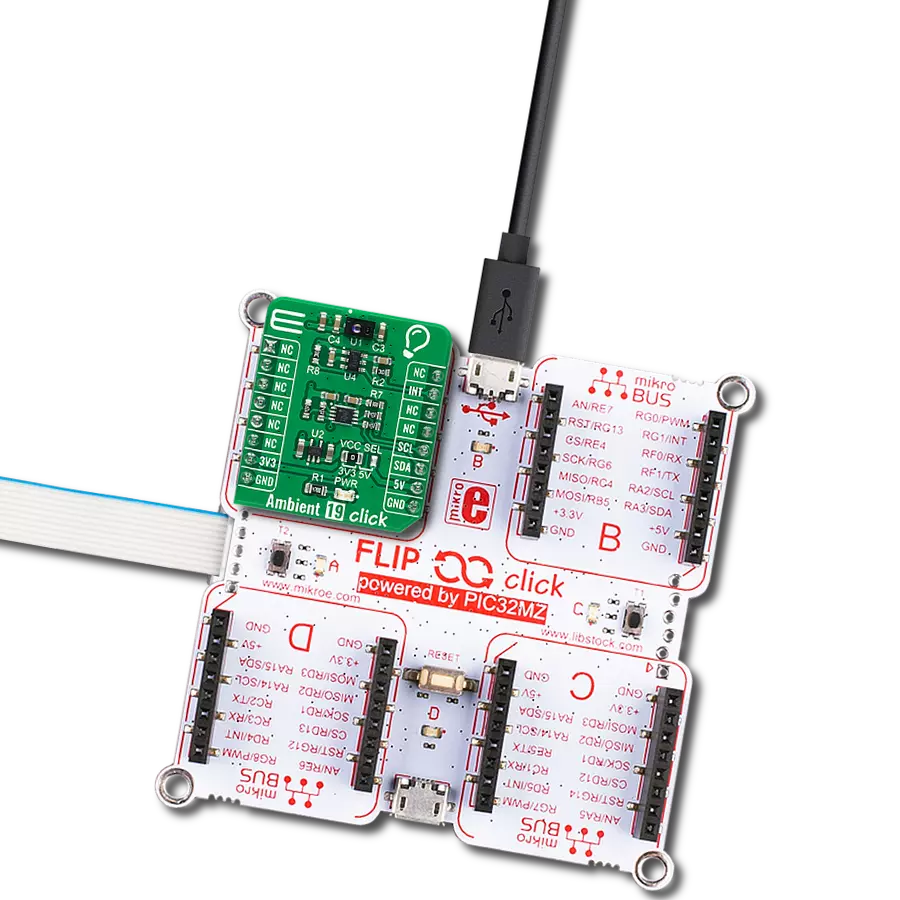

Development board

UNI Clicker is a compact development board designed as a complete solution that brings the flexibility of add-on Click boards™ to your favorite microcontroller, making it a perfect starter kit for implementing your ideas. It supports a wide range of microcontrollers, such as different ARM, PIC32, dsPIC, PIC, and AVR from various vendors like Microchip, ST, NXP, and TI (regardless of their number of pins), four mikroBUS™ sockets for Click board™ connectivity, a USB connector, LED indicators, buttons, a debugger/programmer connector, and two 26-pin headers for interfacing with external electronics. Thanks to innovative manufacturing technology, it allows you to build

gadgets with unique functionalities and features quickly. Each part of the UNI Clicker development kit contains the components necessary for the most efficient operation of the same board. In addition to the possibility of choosing the UNI Clicker programming method, using a third-party programmer or CODEGRIP/mikroProg connected to onboard JTAG/SWD header, the UNI Clicker board also includes a clean and regulated power supply module for the development kit. It provides two ways of board-powering; through the USB Type-C (USB-C) connector, where onboard voltage regulators provide the appropriate voltage levels to each component on the board, or using a Li-Po/Li

Ion battery via an onboard battery connector. All communication methods that mikroBUS™ itself supports are on this board (plus USB HOST/DEVICE), including the well-established mikroBUS™ socket, a standardized socket for the MCU card (SiBRAIN standard), and several user-configurable buttons and LED indicators. UNI Clicker is an integral part of the Mikroe ecosystem, allowing you to create a new application in minutes. Natively supported by Mikroe software tools, it covers many aspects of prototyping thanks to a considerable number of different Click boards™ (over a thousand boards), the number of which is growing every day.

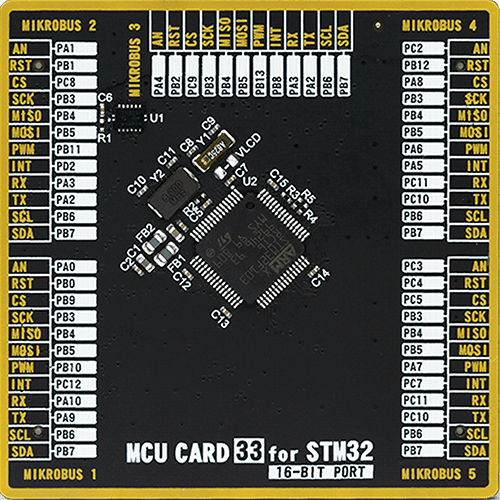

Microcontroller Overview

MCU Card / MCU

Type

8th Generation

Architecture

ARM Cortex-M3

MCU Memory (KB)

256

Silicon Vendor

STMicroelectronics

Pin count

64

RAM (Bytes)

49152

Used MCU Pins

mikroBUS™ mapper

Take a closer look

Click board™ Schematic

Step by step

Project assembly

Software Support

Library Description

This library contains API for LightRanger 10 Click driver.

Key functions:

lightranger10_get_int_pinThis function returns the INT pin logic state.lightranger10_clear_interruptsThis function clears the interrupts.lightranger10_get_distanceThis function reads the target object distance in millimeters.

Open Source

Code example

The complete application code and a ready-to-use project are available through the NECTO Studio Package Manager for direct installation in the NECTO Studio. The application code can also be found on the MIKROE GitHub account.

/*!

* @file main.c

* @brief LightRanger10 Click example

*

* # Description

* This example demonstrates the use of LightRanger 10 Click board by reading

* and displaying the target object distance in millimeters.

*

* The demo application is composed of two sections :

*

* ## Application Init

* Initializes the driver, performs the Click default configuration, and then calibrates

* the sensor to the object positioned at 200mm distance from the sensor.

*

* ## Application Task

* Waits for the data ready interrupt, then clears the interrupt and reads the target distance

* in millimeters and displays the results on the USB UART every 200ms approximately.

*

* @author Stefan Filipovic

*

*/

#include "board.h"

#include "log.h"

#include "lightranger10.h"

static lightranger10_t lightranger10;

static log_t logger;

void application_init ( void )

{

log_cfg_t log_cfg; /**< Logger config object. */

lightranger10_cfg_t lightranger10_cfg; /**< Click config object. */

/**

* Logger initialization.

* Default baud rate: 115200

* Default log level: LOG_LEVEL_DEBUG

* @note If USB_UART_RX and USB_UART_TX

* are defined as HAL_PIN_NC, you will

* need to define them manually for log to work.

* See @b LOG_MAP_USB_UART macro definition for detailed explanation.

*/

LOG_MAP_USB_UART( log_cfg );

log_init( &logger, &log_cfg );

log_info( &logger, " Application Init " );

// Click initialization.

lightranger10_cfg_setup( &lightranger10_cfg );

LIGHTRANGER10_MAP_MIKROBUS( lightranger10_cfg, MIKROBUS_1 );

if ( I2C_MASTER_ERROR == lightranger10_init( &lightranger10, &lightranger10_cfg ) )

{

log_error( &logger, " Communication init." );

for ( ; ; );

}

if ( LIGHTRANGER10_ERROR == lightranger10_default_cfg ( &lightranger10 ) )

{

log_error( &logger, " Default configuration." );

for ( ; ; );

}

log_printf( &logger, " --- Sensor calibration --- \r\n" );

log_printf( &logger, " Place an object at 200mm distance from sensor in the next 5 seconds.\r\n" );

Delay_ms ( 1000 );

Delay_ms ( 1000 );

Delay_ms ( 1000 );

Delay_ms ( 1000 );

Delay_ms ( 1000 );

log_printf( &logger, " Sensor calibration is in progress...\r\n" );

if ( LIGHTRANGER10_ERROR == lightranger10_calibrate_distance ( &lightranger10, 200 ) )

{

log_error( &logger, " Sensor calibration." );

for ( ; ; );

}

log_info( &logger, " Application Task " );

}

void application_task ( void )

{

while ( lightranger10_get_int_pin ( &lightranger10 ) );

uint16_t distance_mm;

if ( ( LIGHTRANGER10_OK == lightranger10_clear_interrupts ( &lightranger10 ) ) &&

( LIGHTRANGER10_OK == lightranger10_get_distance ( &lightranger10, &distance_mm ) ) )

{

log_printf ( &logger, " Distance: %u mm \r\n\n", distance_mm );

}

}

int main ( void )

{

/* Do not remove this line or clock might not be set correctly. */

#ifdef PREINIT_SUPPORTED

preinit();

#endif

application_init( );

for ( ; ; )

{

application_task( );

}

return 0;

}

// ------------------------------------------------------------------------ END