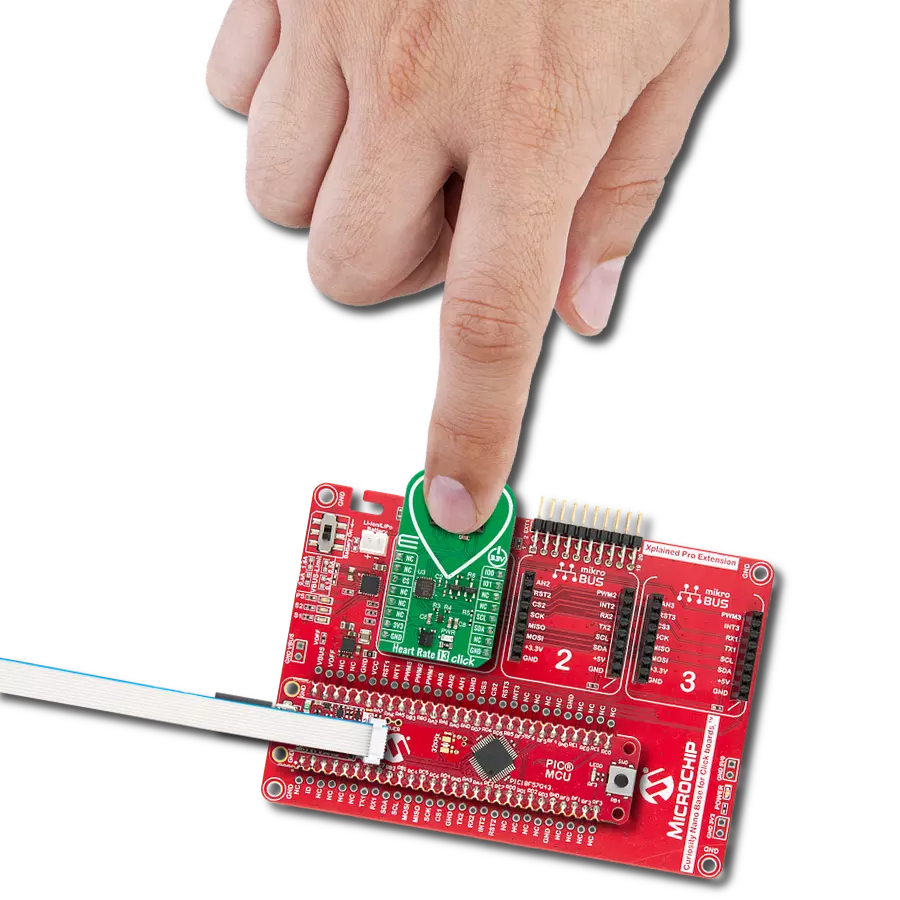

Perfect for use in wearables, providing continuous heart monitoring for fitness tracking or medical purposes without the need for additional equipment

A

A

Hardware Overview

How does it work?

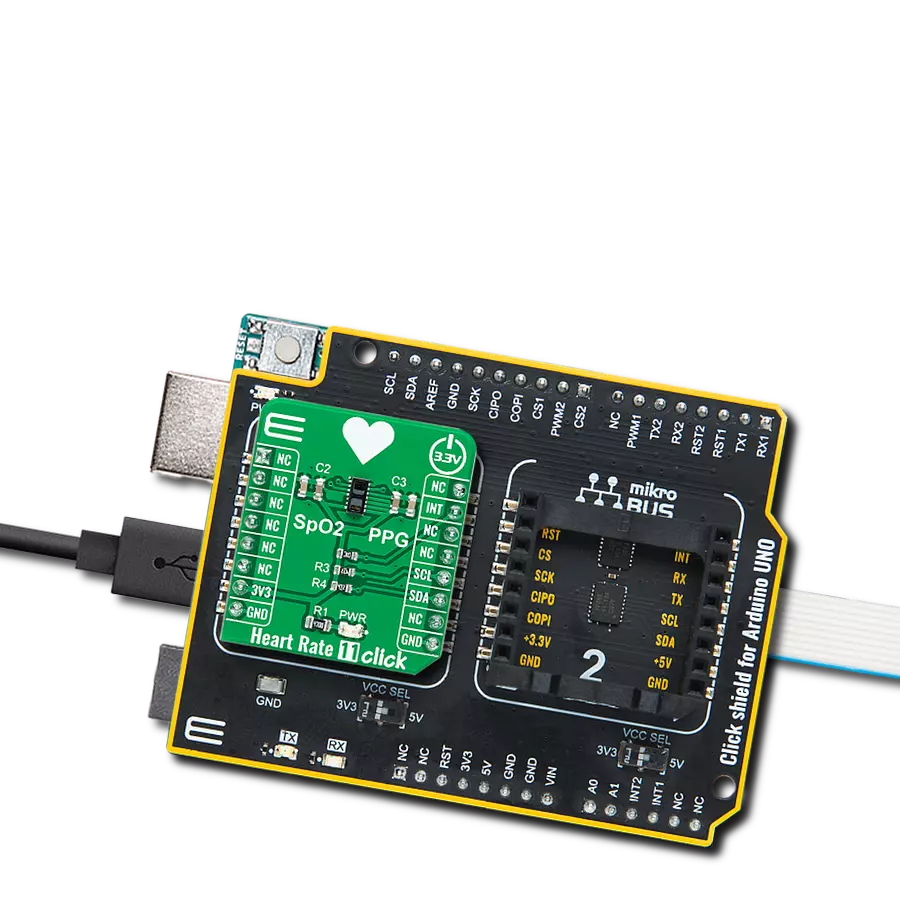

ECG 6 Click is based on the MAX86150, a complete electrocardiogram (ECG) from Analog Devices. It is designed for mobile health. The Click board™ has many features to provide health measurements: electrocardiogram, pulse oximetry, and heart rate. All these features allow ECG 6 click to be used in a range of health-related ECG, SpO2 subsystem, and HR applications, including fitness and activity heart rate monitors, portable ECG, wearable and remote health monitors, and similar. The MAX86150 contains an integrated SpO2 subsystem. The SpO2 subsystem is peripheral capillary oxygen saturation. It is measured by a device called a pulse oximeter. A clip is placed on the user's finger or foot, and light is sent through the finger and measured on the other side.

The MAX86150 integrates red and infrared LED drivers to modulate LED pulses for SpO2 and HR measurements. The LED current can be programmed from 0mA to 100mA with proper VLED supply voltage. The LED pulse width can be programmed from 50μs to 400μs to optimize the accuracy of results and power consumption based on use cases. ECG 6 Click allows several types of electrodes to be used. It supports both stainless-steel and silver-chloride electrode types. The electrodes are used to perform differential measurements of the voltage generated by the heart. Therefore, the heart can be monitored from a single plane only - the coronal plane. However, this is quite enough for fitness, heart rate monitoring, and similar applications. The extensive

interrupt engine can trigger the host MCU from various sources, including interrupt events due to lead detection, R-R detection, fast-recovery event, FIFO buffer states, and many more. These interrupt sources can trigger a state change on the interrupt pin (INT) of the MAX86150 IC. This pin is active-low. This Click board™ can operate with either 3.3V or 5V logic voltage levels selected via the VCC SEL jumper. This way, both 3.3V and 5V capable MCUs can use the communication lines properly. However, the Click board™ comes equipped with a library containing easy-to-use functions and an example code that can be used, as a reference, for further development.

Features overview

Development board

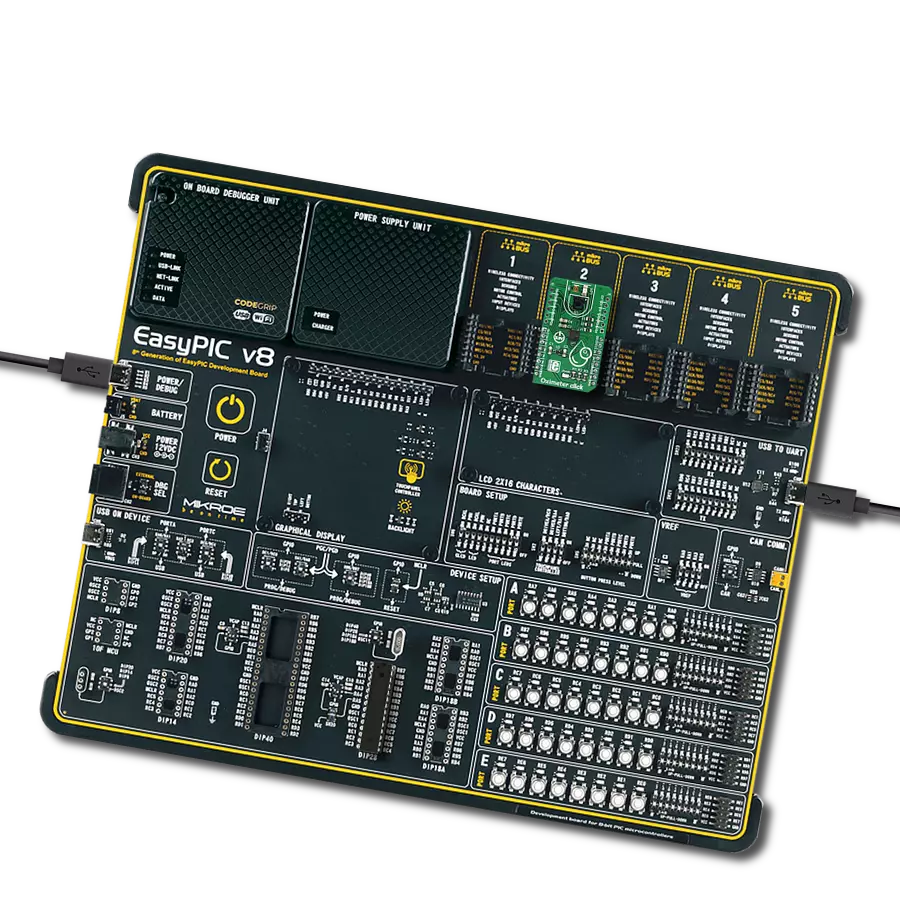

EasyAVR v7 is the seventh generation of AVR development boards specially designed for the needs of rapid development of embedded applications. It supports a wide range of 16-bit AVR microcontrollers from Microchip and has a broad set of unique functions, such as a powerful onboard mikroProg programmer and In-Circuit debugger over USB. The development board is well organized and designed so that the end-user has all the necessary elements in one place, such as switches, buttons, indicators, connectors, and others. With four different connectors for each port, EasyAVR v7 allows you to connect accessory boards, sensors, and custom electronics more

efficiently than ever. Each part of the EasyAVR v7 development board contains the components necessary for the most efficient operation of the same board. An integrated mikroProg, a fast USB 2.0 programmer with mikroICD hardware In-Circuit Debugger, offers many valuable programming/debugging options and seamless integration with the Mikroe software environment. Besides it also includes a clean and regulated power supply block for the development board. It can use a wide range of external power sources, including an external 12V power supply, 7-12V AC or 9-15V DC via DC connector/screw terminals, and a power source via the USB Type-B (USB-B)

connector. Communication options such as USB-UART and RS-232 are also included, alongside the well-established mikroBUS™ standard, three display options (7-segment, graphical, and character-based LCD), and several different DIP sockets which cover a wide range of 16-bit AVR MCUs. EasyAVR v7 is an integral part of the Mikroe ecosystem for rapid development. Natively supported by Mikroe software tools, it covers many aspects of prototyping and development thanks to a considerable number of different Click boards™ (over a thousand boards), the number of which is growing every day.

Microcontroller Overview

MCU Card / MCU

Architecture

AVR

MCU Memory (KB)

32

Silicon Vendor

Microchip

Pin count

40

RAM (Bytes)

2048

You complete me!

Accessories

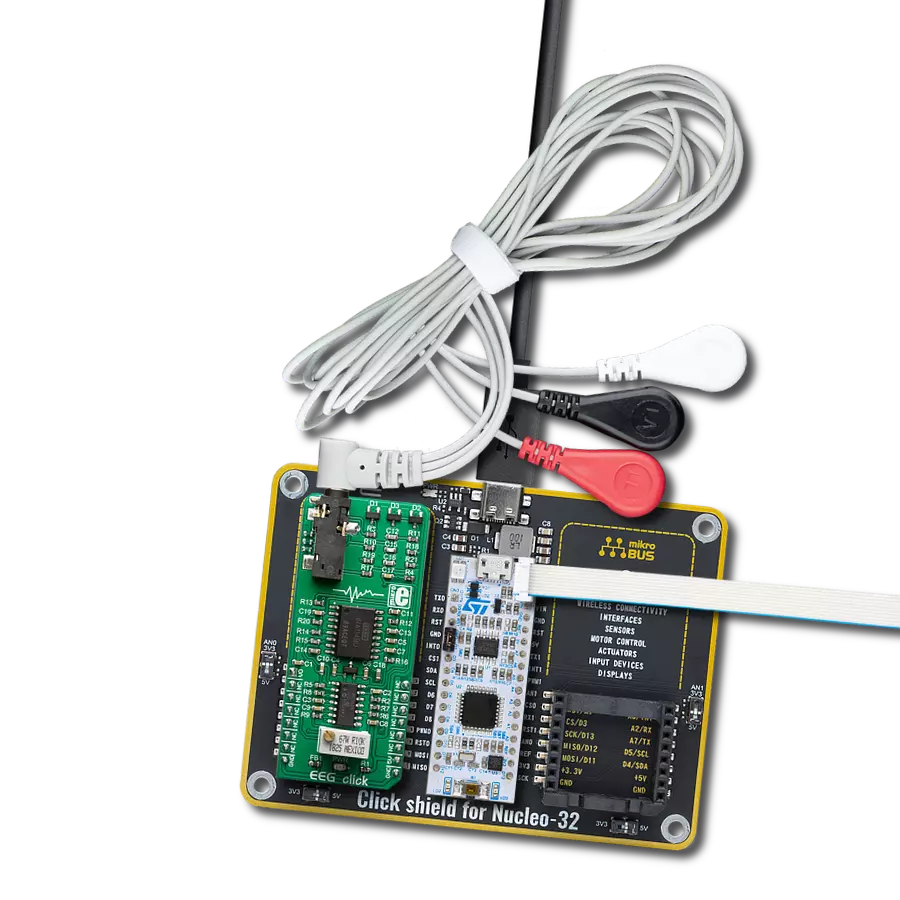

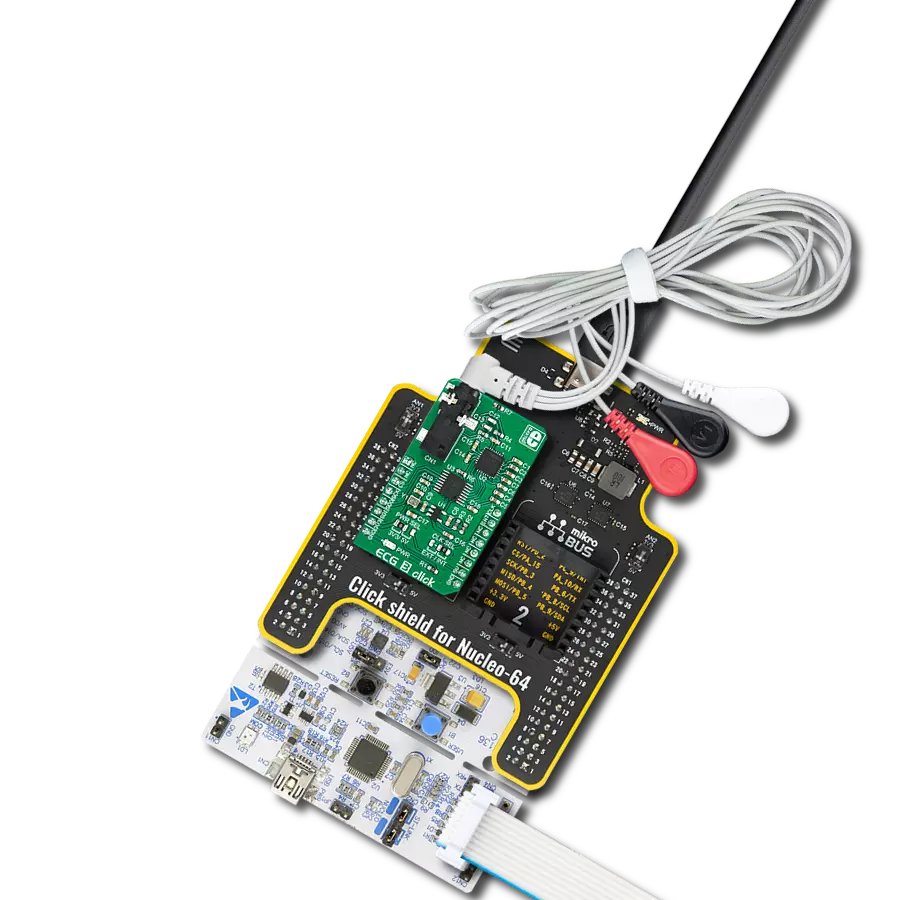

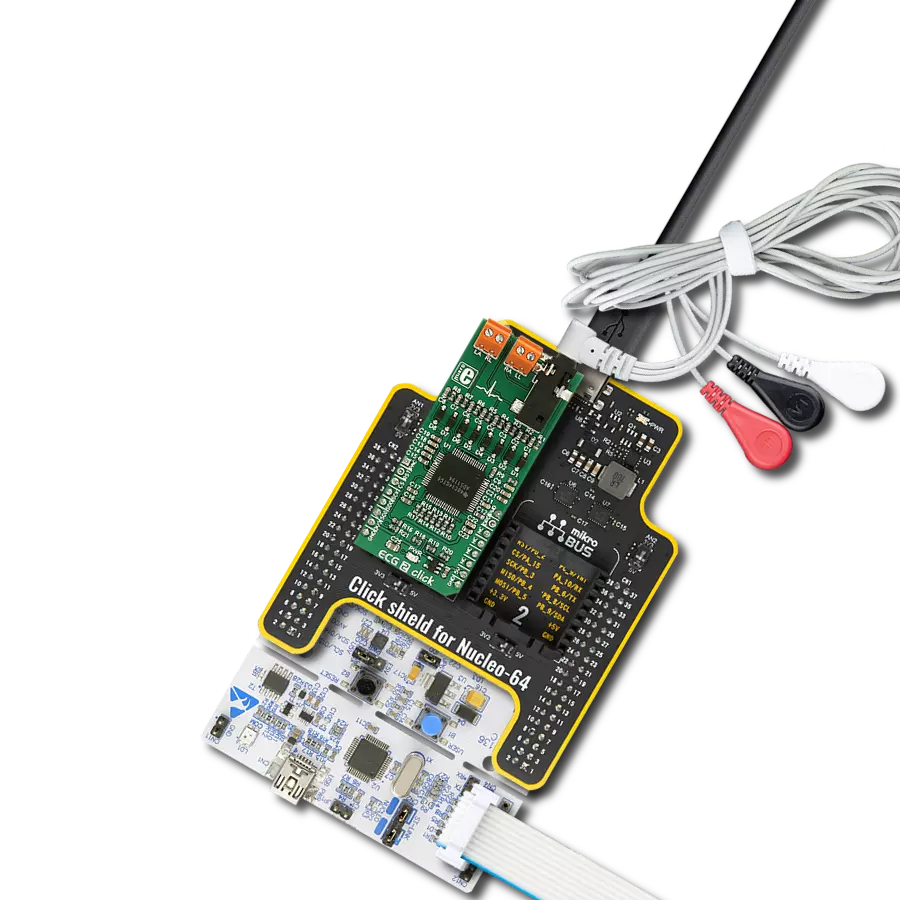

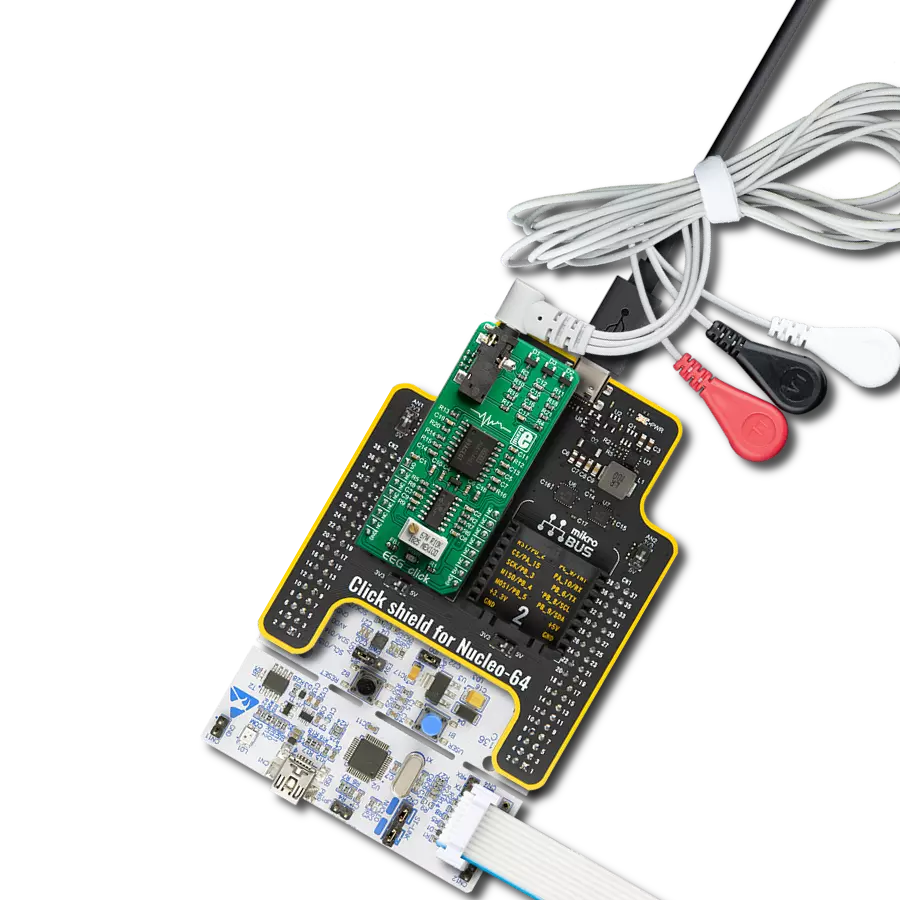

3-wire ECG/EMG cable comes with a convenient 3.5mm phone jack, and it is designed for electrocardiogram recording. This 1m cable is a practical companion for medical professionals and enthusiasts. To complement this cable, you can also use single-use adhesive ECG/EMG electrodes measuring 48x34mm, each equipped with an ECG/EMG cable stud adapter. These electrodes ensure a seamless experience when paired with our ECG/EMG cable and guarantee reliable ECG/EMG signal transmission for comprehensive cardiac monitoring. Trust in the accuracy and convenience of this setup to effortlessly record electrocardiograms and electromyograms with confidence.

Used MCU Pins

mikroBUS™ mapper

Take a closer look

Click board™ Schematic

Step by step

Project assembly

Software Support

Library Description

This library contains API for ECG 6 Click driver.

Key functions:

ecg6_get_sample_data- This function gets one sample from FIFOplot_ecg_data- Sends ECG sensor data to SerialPlotplot_ppg_data- Sends PPG sensor data to SerialPlot

Open Source

Code example

The complete application code and a ready-to-use project are available through the NECTO Studio Package Manager for direct installation in the NECTO Studio. The application code can also be found on the MIKROE GitHub account.

/*!

* \file

* \brief Ecg6 Click example

*

* # Description

* ECG 6 Click contain integrated electrocardiogram, pulse oximeter,

* heart rate monitor sensor module.

*

* The demo application is composed of two sections :

*

* ## Application Init

* Initialize I2C module and all necessary pins. Checking communication accuracy

* and running default configuration for measurement.

*

* ## Application Task

* Measures an ECG signal or PPG sensor and draws a graph on a SerialPlot

*

* ##Additional Functions :

* - plot_ecg_data ( ) - Sends ECG sensor data to SerialPlot

* - plot_ppg_data ( ) - Sends PPG sensor data to SerialPlot

*

*

* *note:*

* When using ECG measurement - PPG measurement must be switched off ...

* Drawing speeds vary for PPG and ECG sensor.

*

* \author MikroE Team

*

*/

// ------------------------------------------------------------------- INCLUDES

#include "board.h"

#include "log.h"

#include "ecg6.h"

// ------------------------------------------------------------------ VARIABLES

static ecg6_t ecg6;

static log_t logger;

static ecg6_int_status_t int_status;

static uint8_t ECG_EXAMPLE = 1;

static uint8_t PPG_EXAMPLE = 0;

static uint8_t DEMO_EXAMPLE;

static uint32_t time_cnt = 0;

static uint8_t device_check;

// ------------------------------------------------------ APPLICATION FUNCTIONS

static void plot_ecg_data ( uint32_t ecg_data )

{

uint32_t tmp;

uint32_t timer;

tmp = ecg_data & 0x3FFFFF;

timer = time_cnt++;

if ( tmp != 0 ) {

log_printf( &logger, "%lu,%lu\r\n", tmp, timer );

Delay_ms ( 5 );

}

}

static void plot_ppg_data ( uint32_t ir_data, uint32_t red_data )

{

uint32_t tmp;

uint32_t tmf;

uint32_t tmd;

tmp = ir_data & 0x0007FFFF;

tmf = red_data & 0x0007FFFF;

tmd = time_cnt++;

if ( ( tmp != 0 ) && ( tmf != 0 ) ) {

log_printf( &logger,"%lu,%lu,%lu\r\n", tmp, tmf, tmd );

Delay_ms ( 20 );

}

}

void application_init ( void )

{

log_cfg_t log_cfg;

ecg6_cfg_t cfg;

/**

* Logger initialization.

* Default baud rate: 115200

* Default log level: LOG_LEVEL_DEBUG

* @note If USB_UART_RX and USB_UART_TX

* are defined as HAL_PIN_NC, you will

* need to define them manually for log to work.

* See @b LOG_MAP_USB_UART macro definition for detailed explanation.

*/

LOG_MAP_USB_UART( log_cfg );

log_init( &logger, &log_cfg );

log_info( &logger, "---- Application Init ----" );

// Click initialization.

ecg6_cfg_setup( &cfg );

ECG6_MAP_MIKROBUS( cfg, MIKROBUS_1 );

ecg6_init( &ecg6, &cfg );

Delay_ms ( 1000 );

DEMO_EXAMPLE = PPG_EXAMPLE;

// Dummy read

ecg6_check_path_id( &ecg6 );

Delay_ms ( 100 );

device_check = ecg6_check_path_id( &ecg6 );

if ( device_check != 0 )

{

log_printf( &logger, " -- > Device ERROR!!! \r\n" );

for ( ; ; );

}

log_printf( &logger, " -- > Device OK!!! \r\n" );

if ( DEMO_EXAMPLE == ECG_EXAMPLE )

{

ecg6_default_cfg( &ecg6 );

}

else

{

ecg6_ppg_default_config( &ecg6 );

}

log_printf( &logger, " ---- Configuration done ----- \r\n" );

Delay_ms ( 1000 );

time_cnt = 0;

}

void application_task ( void )

{

ecg6_element_t sample;

if ( ecg6_int_pin_state(&ecg6) == 0 ) {

ecg6_get_sample_data( &ecg6, &sample, 0x00 );

if ( DEMO_EXAMPLE == ECG_EXAMPLE )

{

plot_ecg_data( sample.element_1 );

}

else

{

plot_ppg_data( sample.element_1, sample.element_2 );

}

}

}

int main ( void )

{

/* Do not remove this line or clock might not be set correctly. */

#ifdef PREINIT_SUPPORTED

preinit();

#endif

application_init( );

for ( ; ; )

{

application_task( );

}

return 0;

}

// ------------------------------------------------------------------------ END