This solution, which employs the Doppler effect with microwaves, provides the ability to detect and track motion with precision, opening doors to a wide range of applications

A

A

Hardware Overview

How does it work?

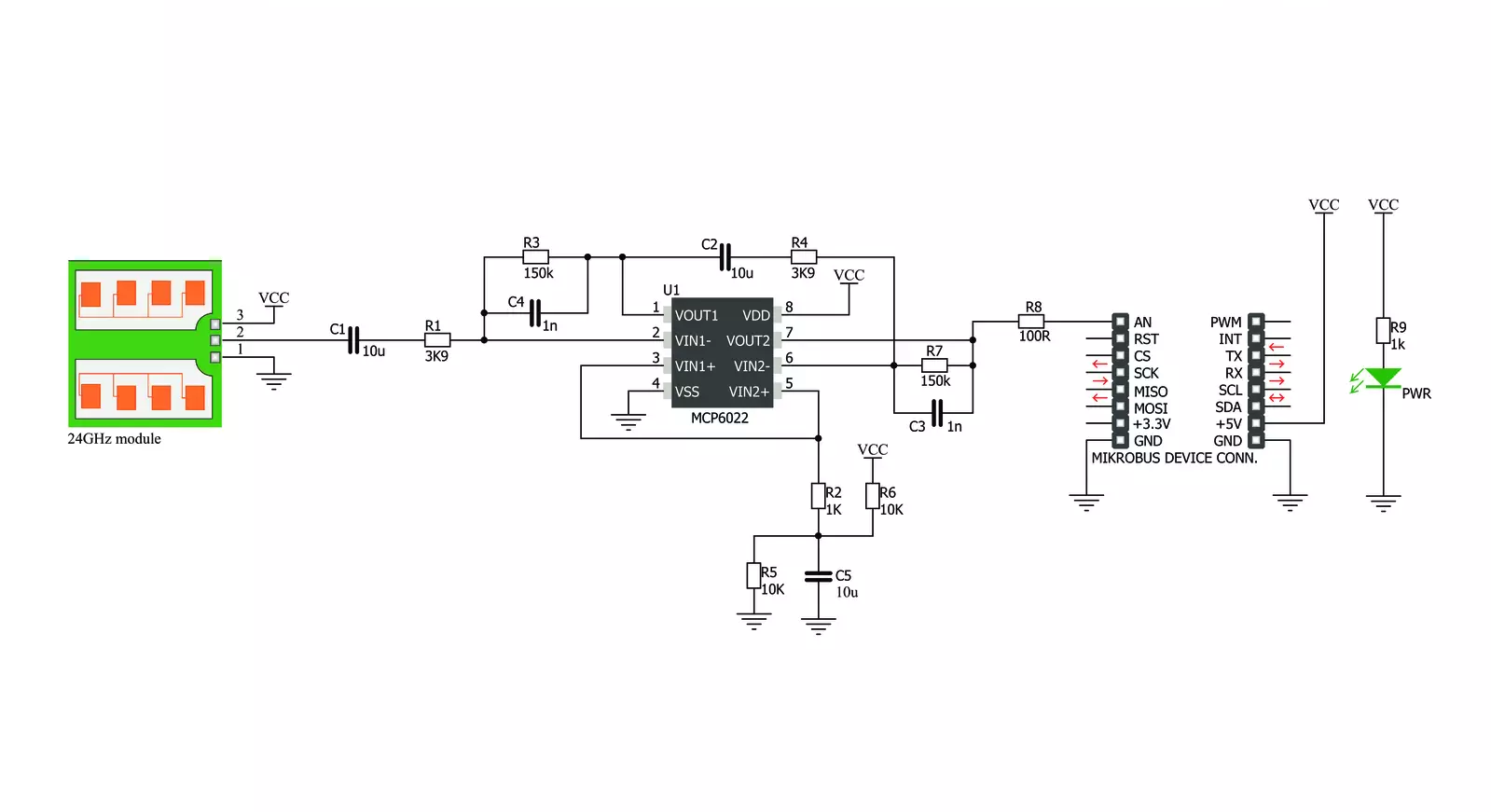

Microwave Click is based on the PD-V11, a 24GHz microwave motion sensor from Pdlux. The typical use for Microwave click is a proximity or motion detector in various applications and devices. The Microwave click can detect movement or proximity by using the Doppler effect. The onboard microwave motions sensor transmits waves, and picks them back as they hit an object, with their frequency changed. Microwave click does not need optical visibility to work, and the waves can penetrate many kinds of barriers and obstacles. Microwave click detects movement of objects utilizing Doppler effect. When the PD-V11 microwave sensor is powered on, it starts transmitting radio waves of fixed frequency. As the waves hit a moving object they are reflected back toward PD-V11 microwave motion sensor, with their frequency changed, depending on speed

and direction of object's movement. The Doppler effect - a change in frequency of a wave for the observer and object move closer or further apart from one another. A typical example of the Doppler effect is when a vehicle with siren passes and you hear the pitch drop of the siren. The PD-V11 microwave motion sensor low power consumption, low noise, and a low wireless power output. See the datasheet to learn more. The PD-V11 microwave motion sensor picks up reflected waves and converts them to a voltage signal. This signal has the magnitude of several hundred microvolts, so it's sent to the MCP6022 which amplifies the signal, in order to make it readable over the Analog pin on the mikroBUS™. This signal is amplified up to 3.3V. Once amplified, the signal is routed to the Analog pin (OUT) on the mikroBUS™ line. The proximity of the object can

be determined by measuring the amplitude of this signal, and speed/direction by determining its frequency. The PD-V11 microwave motion sensor low power consumption, low noise, and a low wireless power output. See the datasheet to learn more. The PD-V11 microwave motion sensor picks up reflected waves and converts them to a voltage signal. This signal has the magnitude of several hundred microvolts, so it's sent to the MCP6022 which amplifies the signal, in order to make it readable over the Analog pin on the mikroBUS™. This signal is amplified up to 3.3V. Once amplified, the signal is routed to the Analog pin (OUT) on the mikroBUS™ line. The proximity of the object can be determined by measuring the amplitude of this signal, and speed/direction by determining its frequency.

Features overview

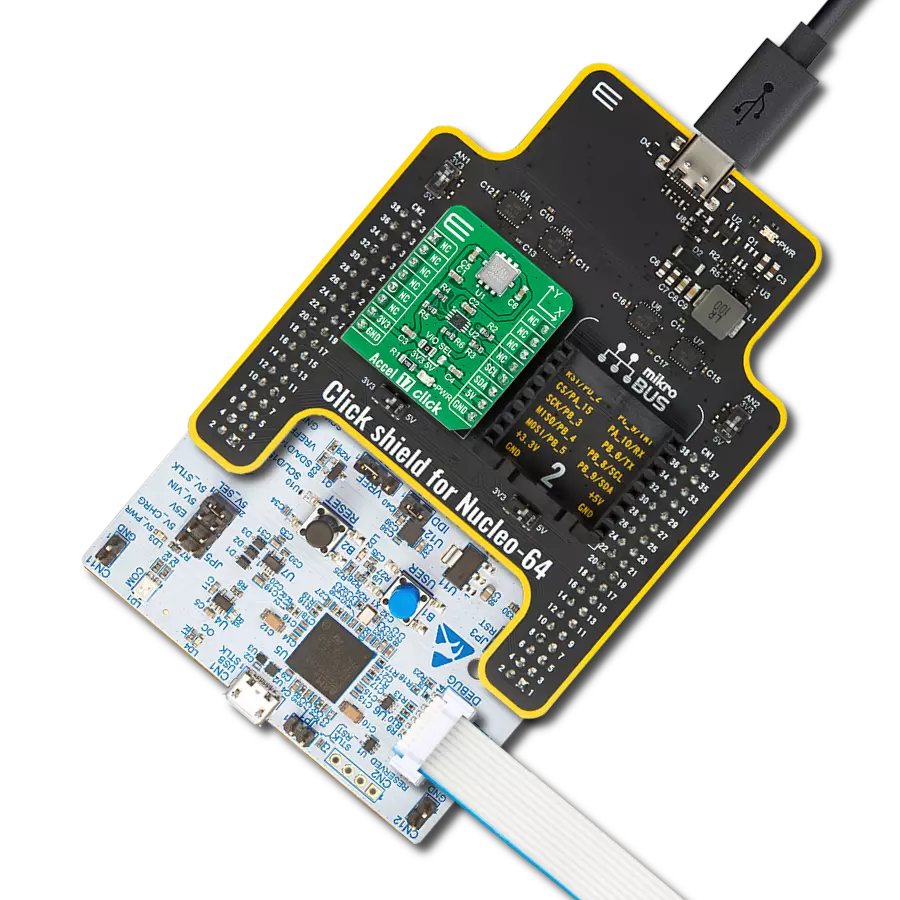

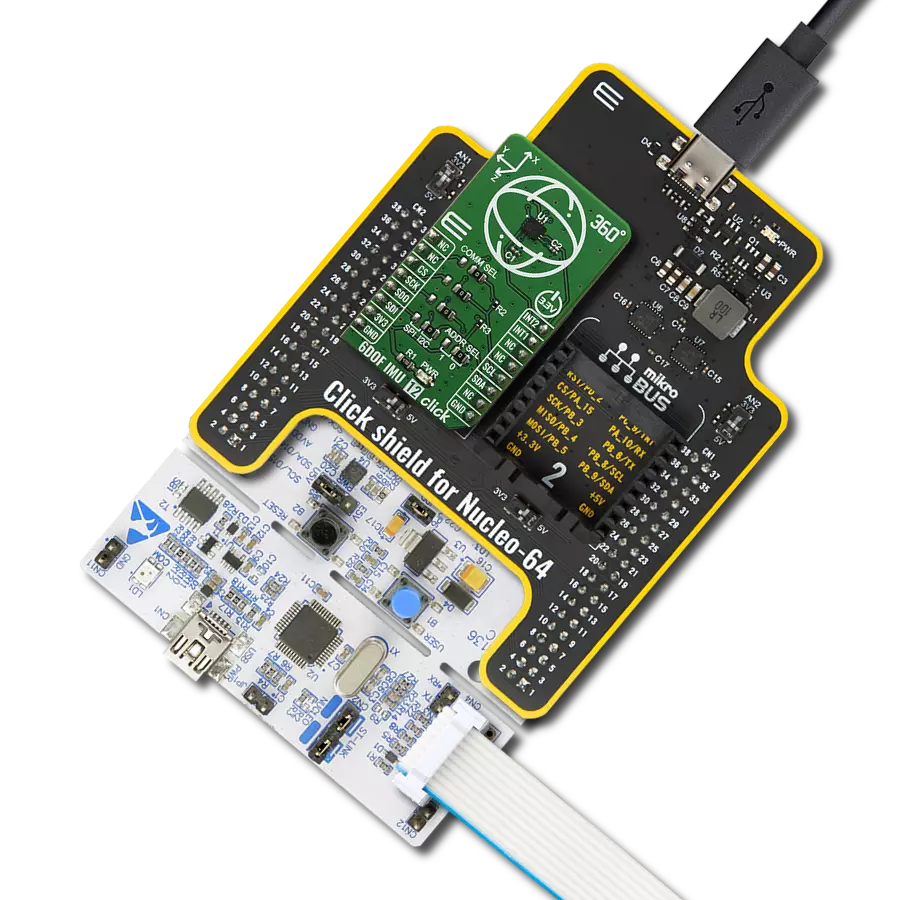

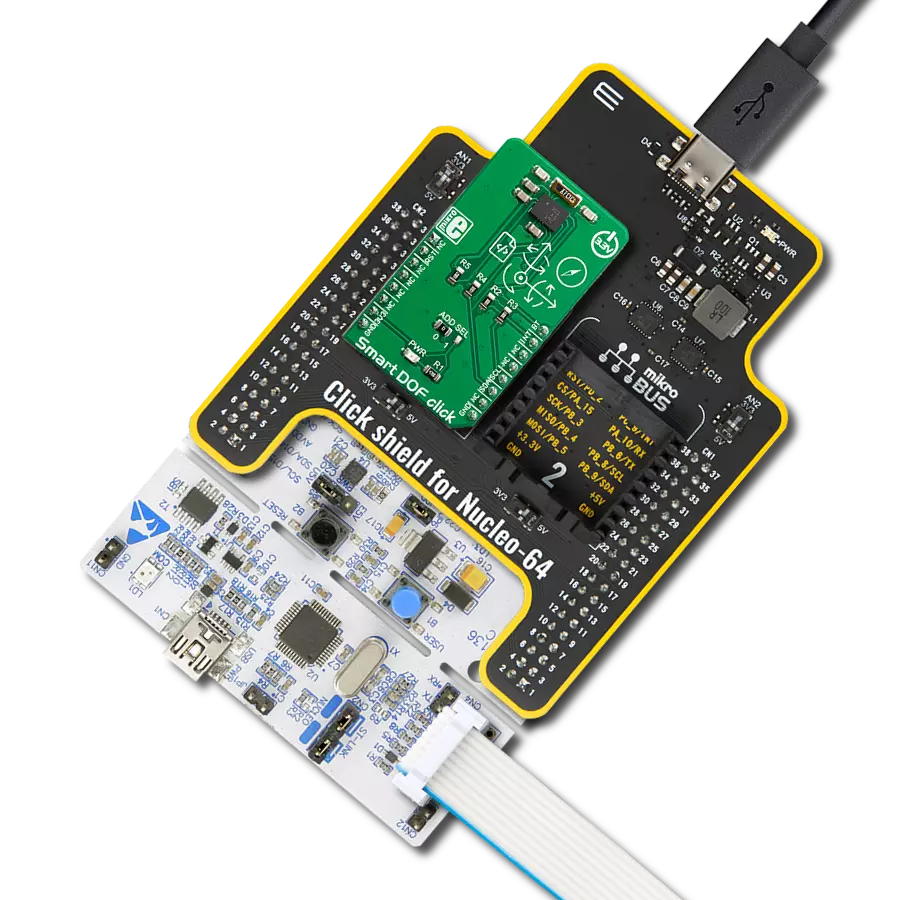

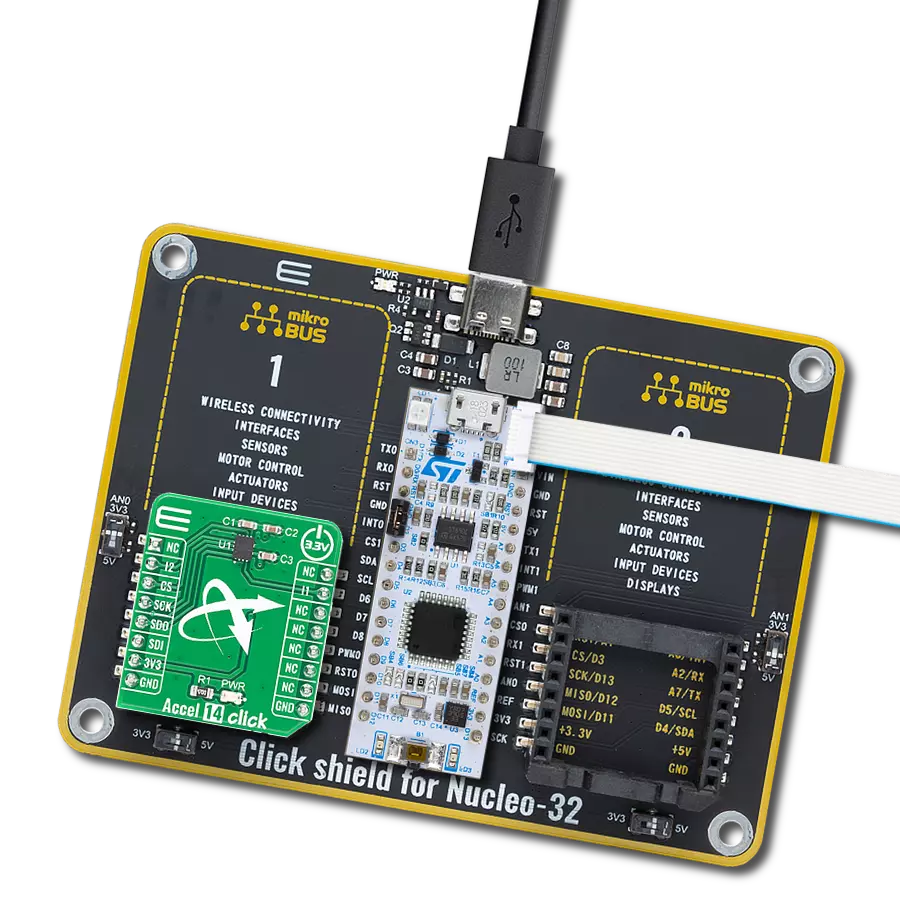

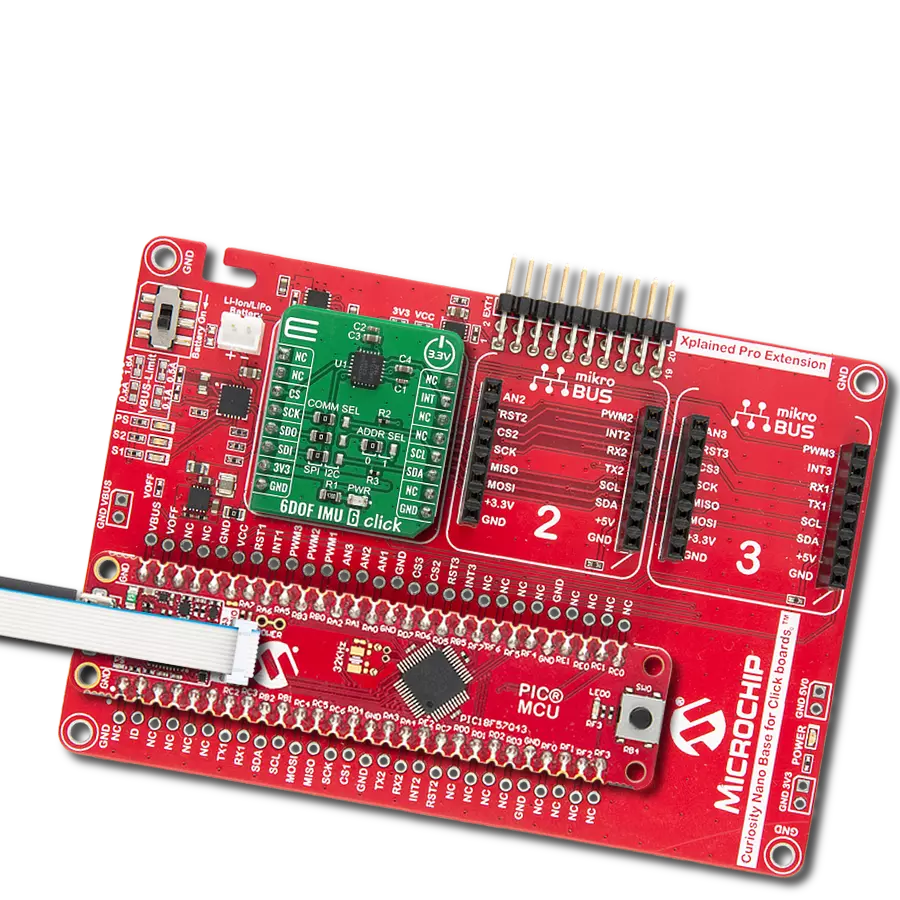

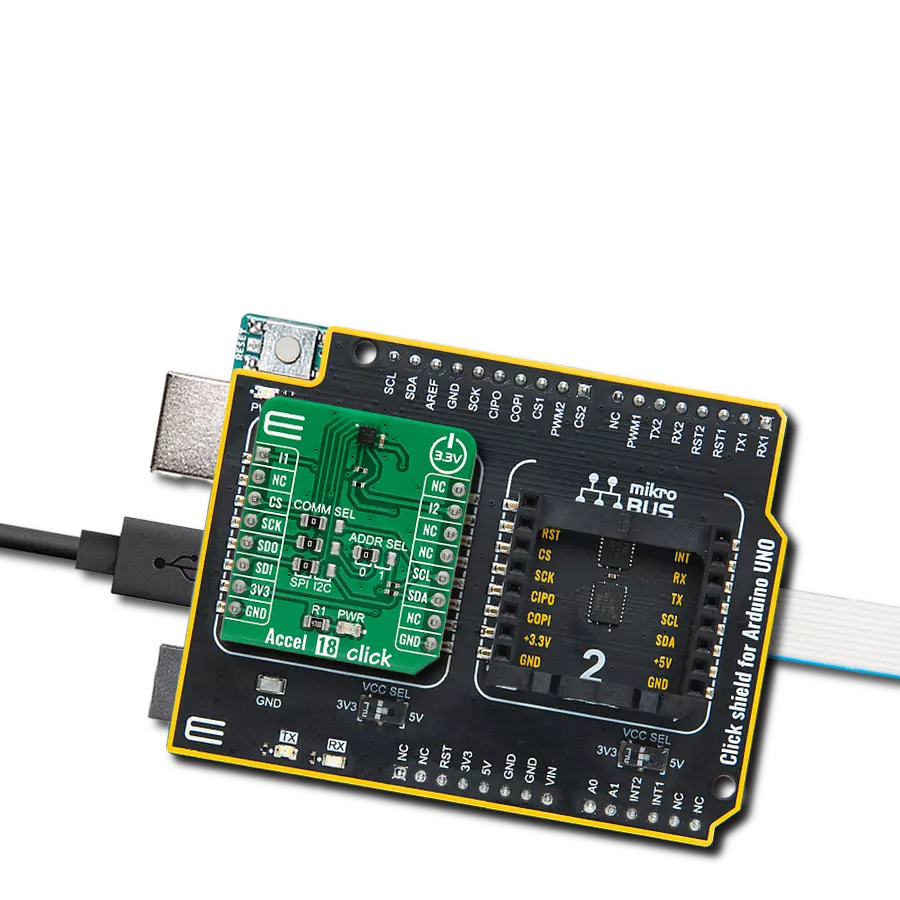

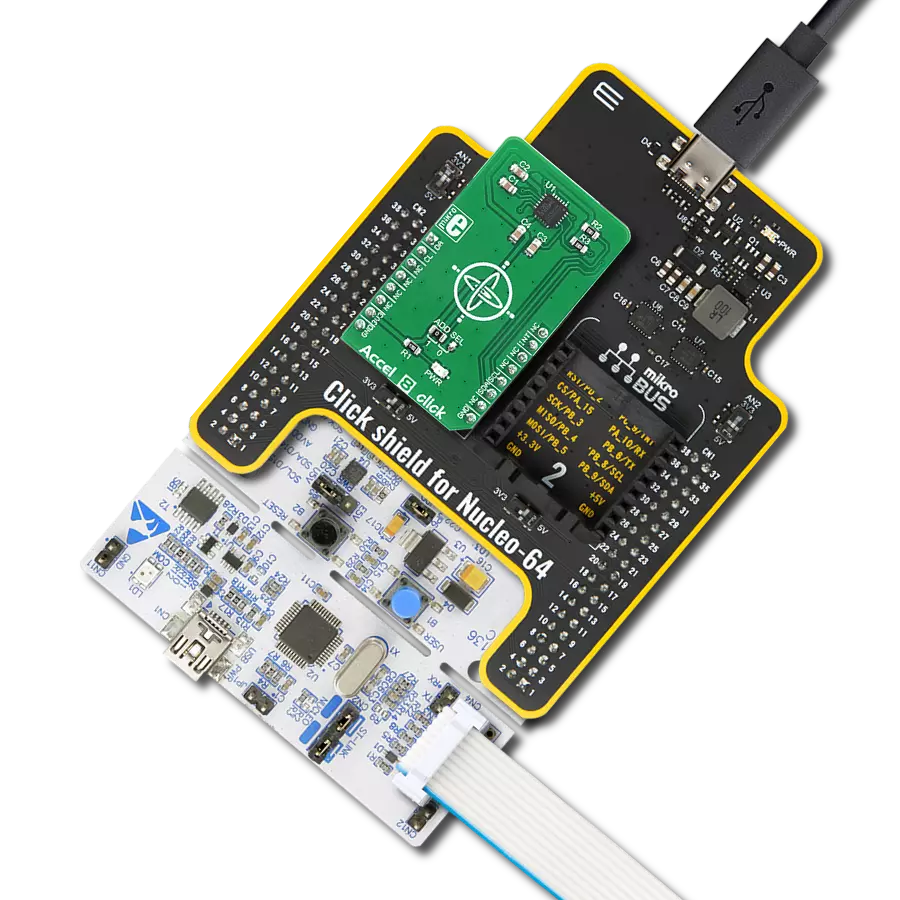

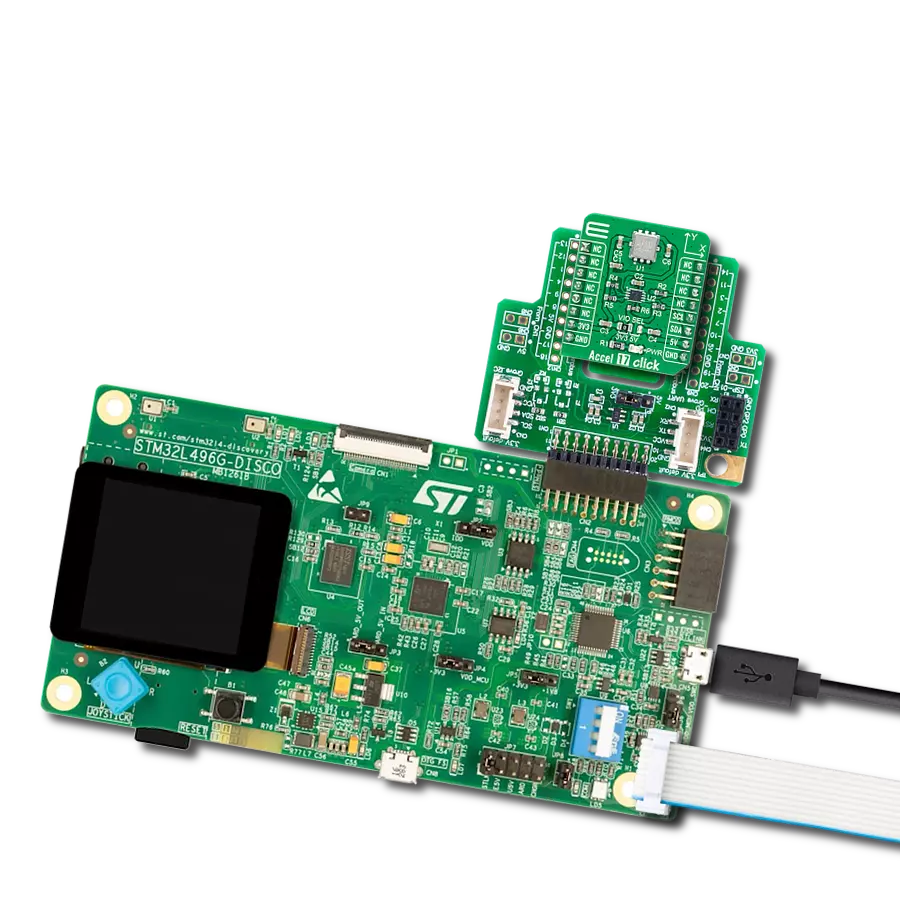

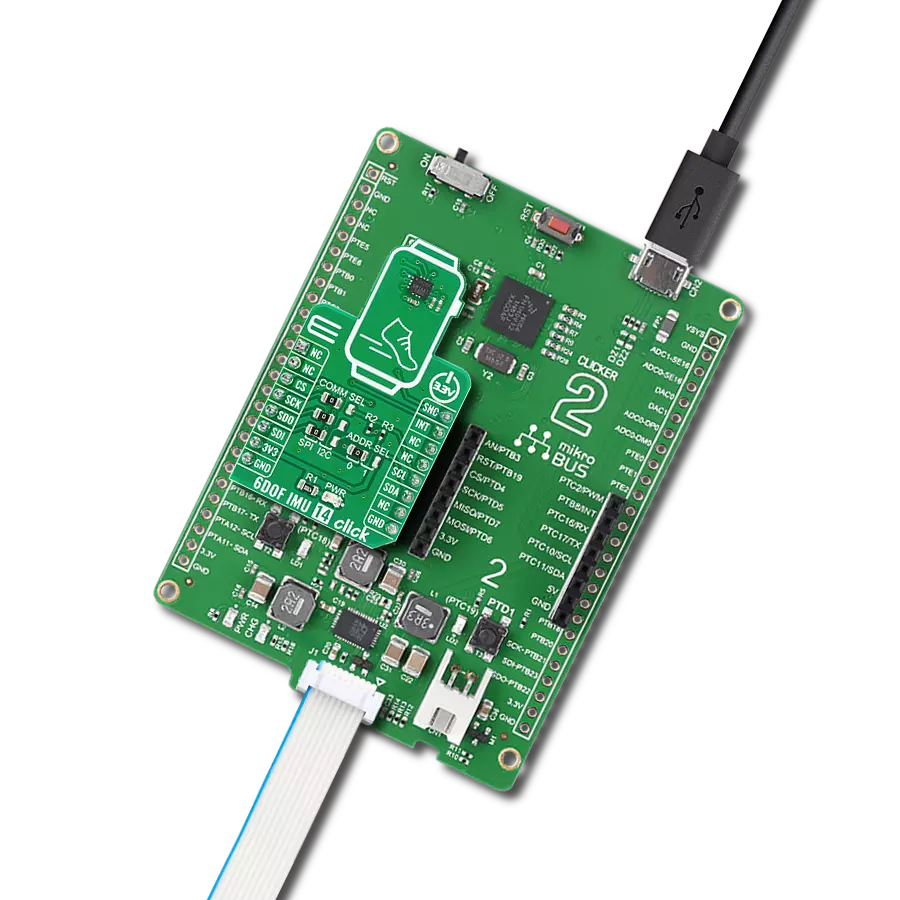

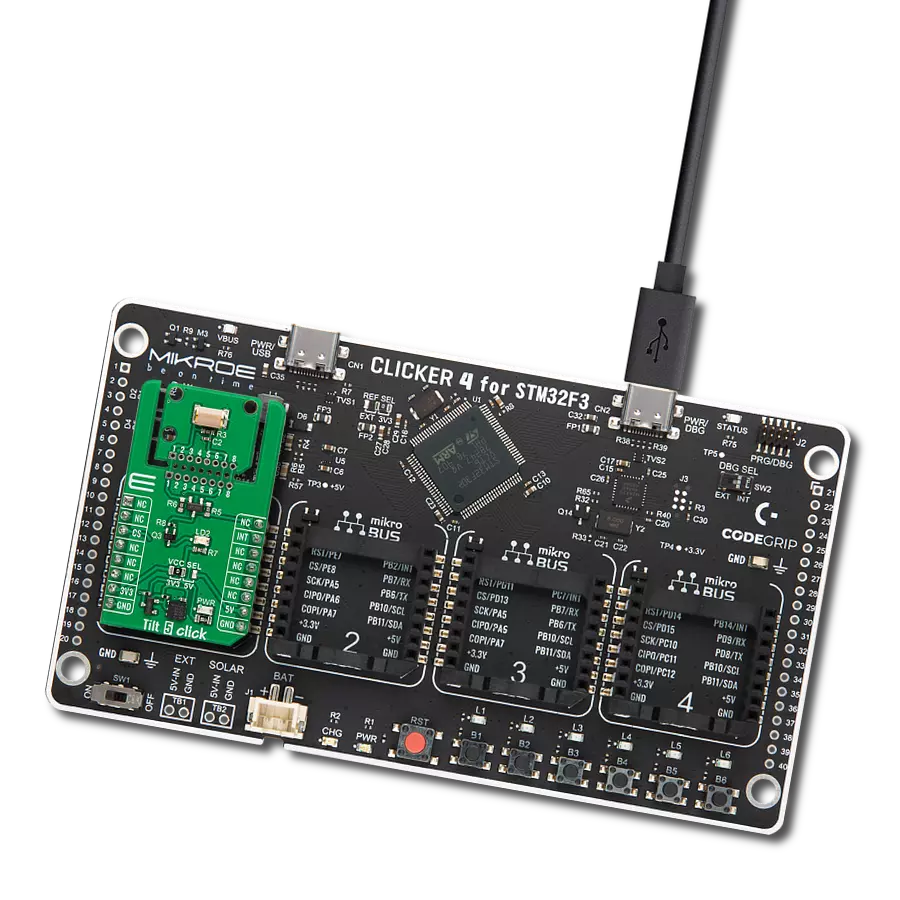

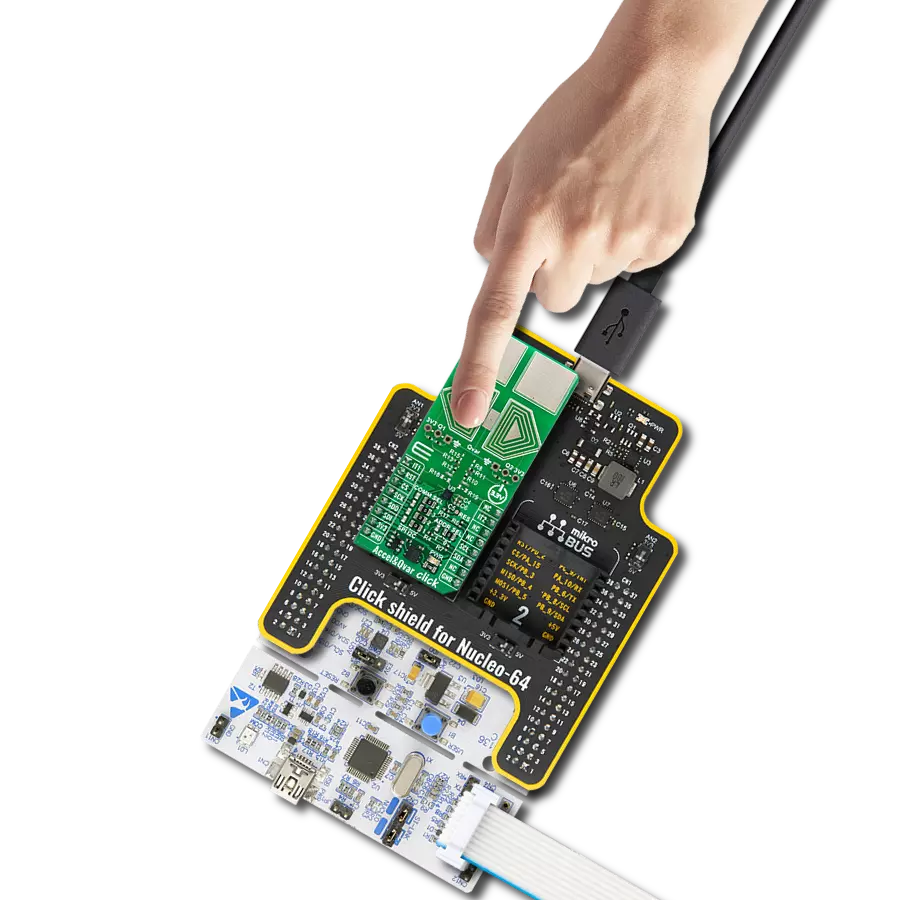

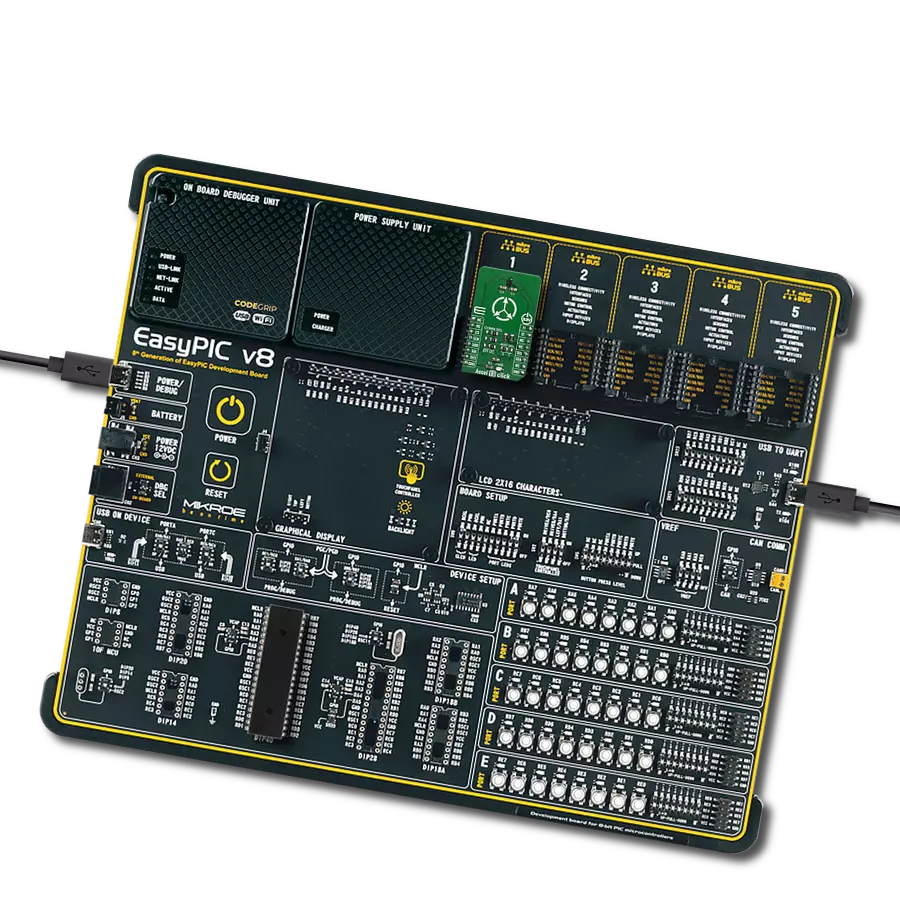

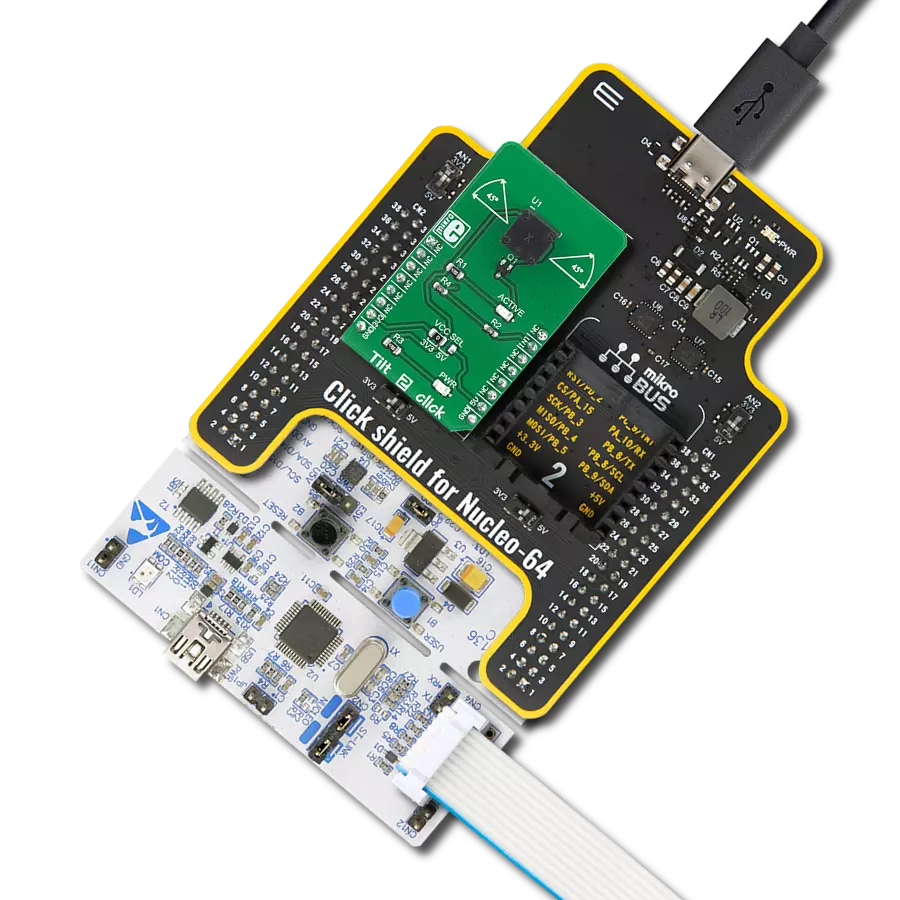

Development board

EasyAVR PRO v8 is a development board specially designed for the needs of rapid development of embedded applications. It supports a wide range of microcontrollers, such as different 8/16-bit AVR® MCUs from Microchip, regardless of their number of pins, and a broad set of unique functions, such as the first-ever embedded debugger/programmer over a WiFi network. The development board is well organized and designed so that the end-user has all the necessary elements, such as switches, buttons, indicators, connectors, and others, in one place. Thanks to innovative manufacturing technology, EasyAVR PRO v8 provides a fluid and immersive working experience, allowing access

anywhere and under any circumstances at any time. Each part of the EasyAVR PRO v8 development board contains the components necessary for the most efficient operation of the same board. An advanced integrated CODEGRIP programmer/debugger module offers many valuable programming/debugging options, including support for JTAG, SWD, and SWO Trace (Single Wire Output)), and seamless integration with the Mikroe software environment. Besides, it also includes a clean and regulated power supply module for the development board. It can use a wide range of external power sources, including a battery, an external 12V power supply, and a power source via

the USB Type-C (USB-C) connector. Communication options such as USB-UART and USB DEVICE are also included, alongside the well-established mikroBUS™ standard, a standardized socket for the MCU card (SiBRAIN standard), and two display options for the TFT board line of products and character-based LCD. EasyAVR PRO v8 is an integral part of the Mikroe ecosystem for rapid development. Natively supported by Mikroe software tools, it covers many aspects of prototyping and development thanks to a considerable number of different Click boards™ (over a thousand boards), the number of which is growing every day.

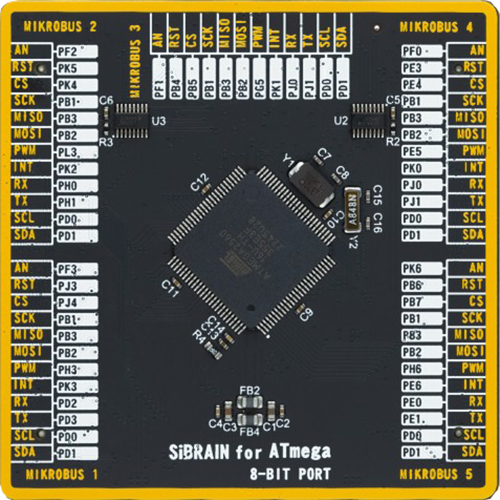

Microcontroller Overview

MCU Card / MCU

Type

8th Generation

Architecture

AVR

MCU Memory (KB)

256

Silicon Vendor

Microchip

Pin count

100

RAM (Bytes)

8192

Used MCU Pins

mikroBUS™ mapper

Take a closer look

Click board™ Schematic

Step by step

Project assembly

Software Support

Library Description

This library contains API for Microwave Click driver.

Key functions:

microwave_generic_read- Generic ADC Read function

Open Source

Code example

The complete application code and a ready-to-use project are available through the NECTO Studio Package Manager for direct installation in the NECTO Studio. The application code can also be found on the MIKROE GitHub account.

/*!

* \file main.c

* \brief Microwave Click example

*

* # Description

* This is an example which demonstrates the use of Microwave Click board.

* Microwave Click reads ADC results, takes exact amount of samples,

* calculation of difference between taken samples and reference ADC value, and

* reports movement if difference is greater/lower than selected threshold value.

*

* The demo application is composed of two sections :

*

* ## Application Init

* Initializes the ADC and uart console where the results will be displayed.

* Also calculates the reference ADC value for Microwave Click board.

*

* ## Application Task

* Reads the AD converted results and compares this results with the previously

* calculated reference value, taking into account the choosen threshold value

* which controls the sensor sensitivity. All data is being displayed on the

* USB UART where you can track their changes.

*

*

* \author Nemanja Medakovic

*

*/

// ------------------------------------------------------------------- INCLUDES

#include "board.h"

#include "log.h"

#include "microwave.h"

// ------------------------------------------------------------------ VARIABLES

static microwave_t microwave;

static log_t logger;

static uint16_t reference;

static uint32_t sum;

static uint16_t old_detector = 0;

// ------------------------------------------------------ APPLICATION FUNCTIONS

void application_init( void )

{

microwave_cfg_t cfg;

log_cfg_t log_cfg;

/**

* Logger initialization.

* Default baud rate: 115200

* Default log level: LOG_LEVEL_DEBUG

* @note If USB_UART_RX and USB_UART_TX

* are defined as HAL_PIN_NC, you will

* need to define them manually for log to work.

* See @b LOG_MAP_USB_UART macro definition for detailed explanation.

*/

LOG_MAP_USB_UART( log_cfg );

log_init( &logger, &log_cfg );

log_info( &logger, "---- Application Init ----" );

// Click initialization.

microwave_cfg_setup( &cfg );

MICROWAVE_MAP_MIKROBUS( cfg, MIKROBUS_1 );

microwave_init( µwave, &cfg );

Delay_ms ( 100 );

log_printf( &logger, " Calibrating the sensor...\r\n" );

log_printf( &logger, " There must be no movement near the sensor!\r\n" );

log_printf( &logger, "*********************************************\r\n" );

Delay_ms ( 1000 );

Delay_ms ( 1000 );

Delay_ms ( 1000 );

sum = 0;

for ( uint8_t cnt = 0; cnt < MICROWAVE_SAMPLES_COUNT_100; cnt++ )

{

sum += microwave_generic_read( µwave );

}

reference = sum / MICROWAVE_SAMPLES_COUNT_100;

log_printf( &logger, " The sensor has been calibrated!\r\n" );

log_printf( &logger, "** Reference value: %d\r\n", reference );

log_printf( &logger, "*********************************************\r\n" );

Delay_ms ( 1000 );

}

void application_task( void )

{

microwave_data_t adc_sample;

uint16_t detector;

uint8_t sampler;

uint8_t cnt = 0;

sum = 0;

for ( sampler = 0; sampler < MICROWAVE_SAMPLES_COUNT_100; sampler++ )

{

adc_sample = microwave_generic_read( µwave );

sum += adc_sample;

cnt++;

}

if ( cnt )

{

detector = sum / cnt;

if ( ( ( detector + MICROWAVE_THRESHOLD_10 ) < reference ||

( detector - MICROWAVE_THRESHOLD_10 ) > reference ) &&

old_detector != detector )

{

log_printf( &logger, "** MOVE DETECTED!\r\n" );

log_printf( &logger, "** Detector value : %d\r\n", detector );

log_printf( &logger, "**************************\r\n" );

old_detector = detector;

Delay_ms ( 100 );

}

}

}

int main ( void )

{

/* Do not remove this line or clock might not be set correctly. */

#ifdef PREINIT_SUPPORTED

preinit();

#endif

application_init( );

for ( ; ; )

{

application_task( );

}

return 0;

}

// ------------------------------------------------------------------------ END