Trigger actions in response to tilting, such as powering down devices when left inactive or activating alarms in security systems

A

A

Hardware Overview

How does it work?

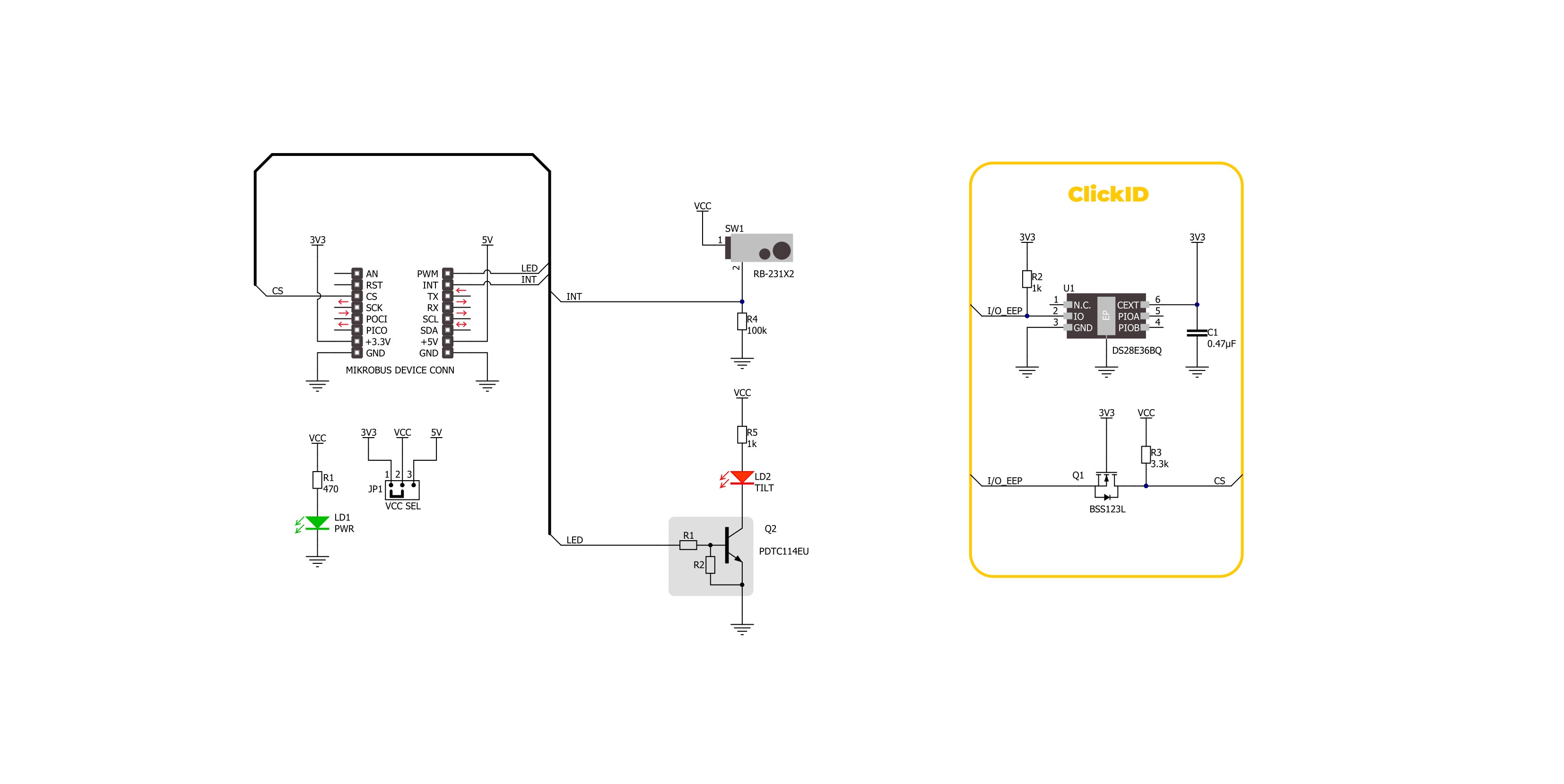

Tilt 4 Click is based on the RB-231X2, a rolling ball tilt switch from C&K Switches (Littelfuse) specially designed for safety control. This switch features a compact, shielded design that allows an angle of detection up to 10°. The conductive ball inside the tube moves to generate the signal and contact. The RB-231X2 offers an impressive operating life of 100,000 cycles, with key specifications including a single-pole single-throw (SPST) contact arrangement, a sensor angle range from 0˚ to 10˚, and dimensions of 9.7 mm in height, 16.6 mm in length, and 5.0 mm in width. It is ideal for movement detection, safety devices, white goods,

and consumer electronic applications. Tilt 4 Click interfaces with the MCU using only two pins: INT and LED pins of the mikroBUS™ socket. The INT pin is an interrupt signal, immediately alerting the MCU upon detecting a tilt event, ensuring prompt response and processing. Meanwhile, the LED pin controls the TILT red LED, which provides a clear visual indication whenever a tilt is detected. This dual-pin configuration simplifies the connection process and enhances the efficiency and reliability of tilt detection and indication. The INT pin's role in delivering real-time interrupt signals is crucial for applications requiring immediate action, while the

LED pin's control over the TILT red LED ensures that the status of the tilt detection is always visible, making it easier to monitor and debug. This Click board™ can operate with either 3.3V or 5V logic voltage levels selected via the VCC SEL jumper. This way, both 3.3V and 5V capable MCUs can use the communication lines properly. Also, this Click board™ comes equipped with a library containing easy-to-use functions and an example code that can be used as a reference for further development.

Features overview

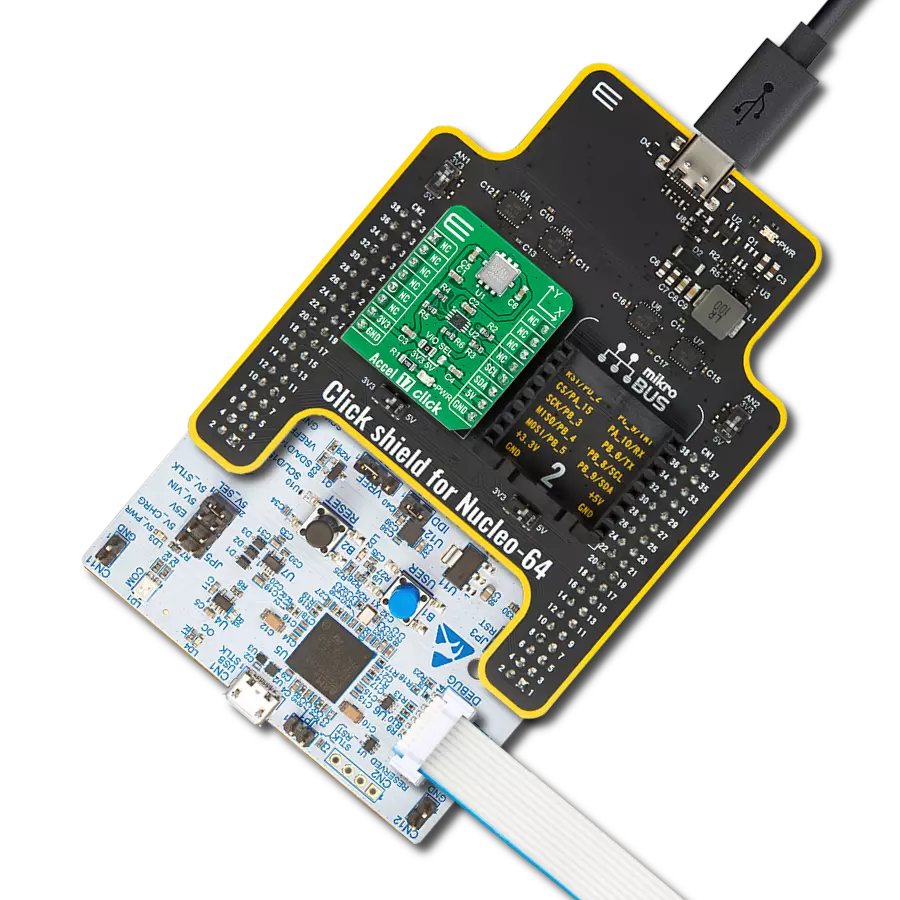

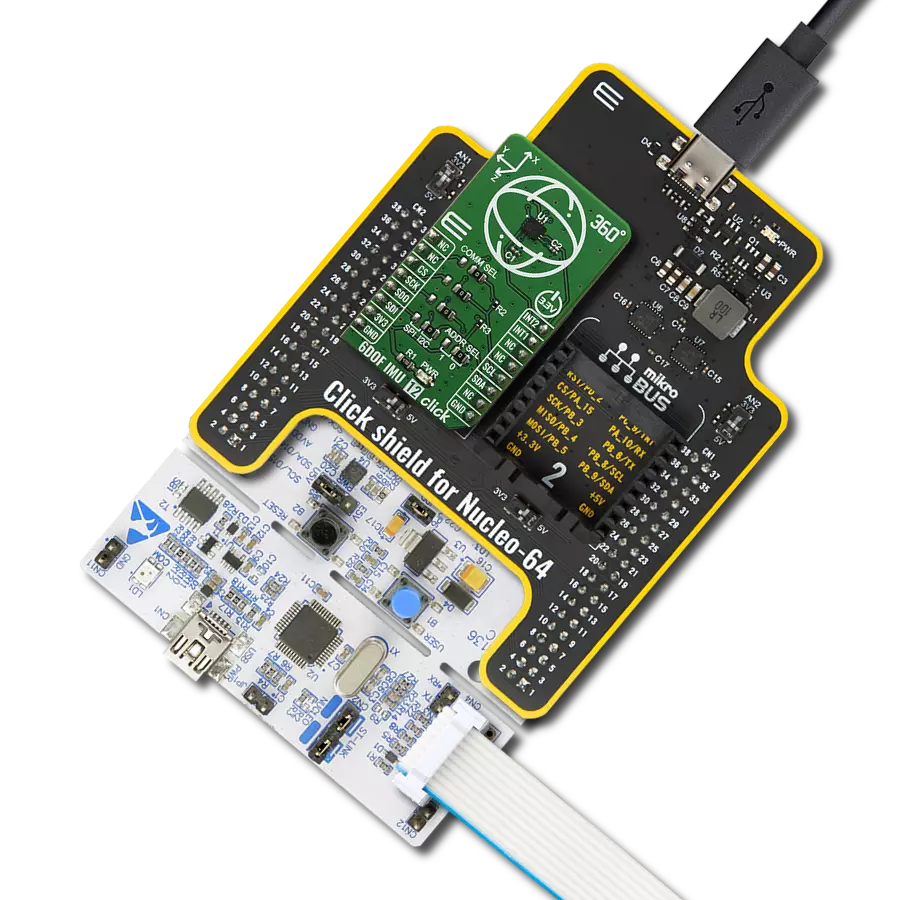

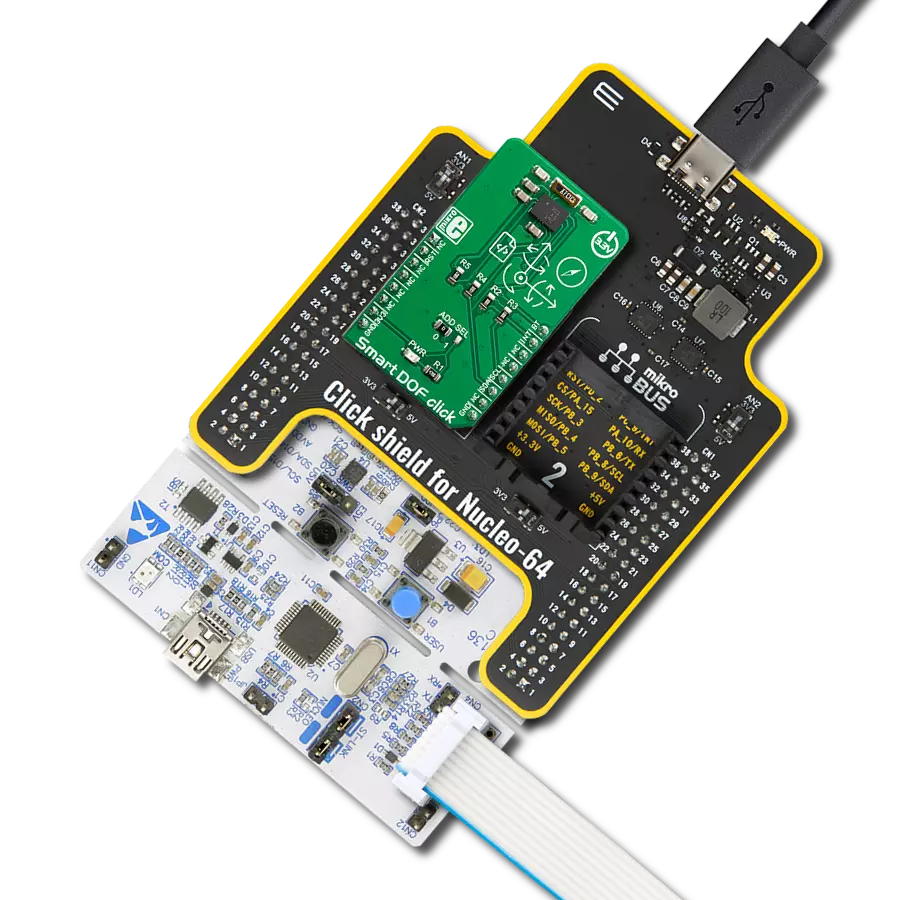

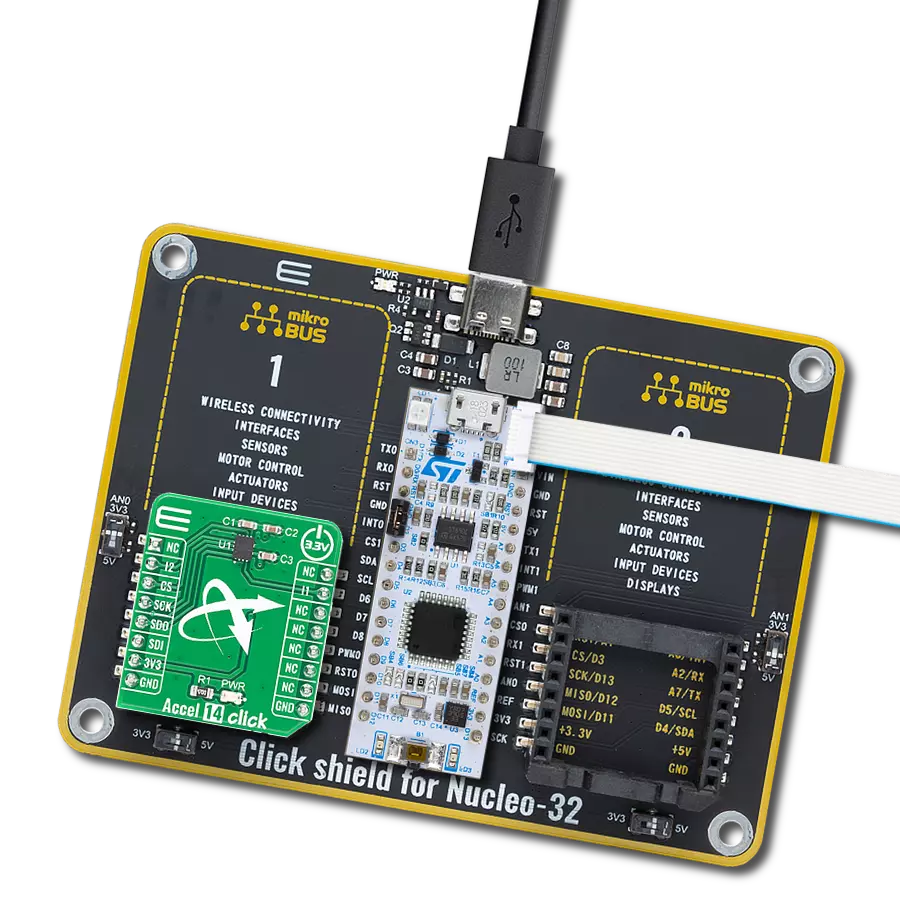

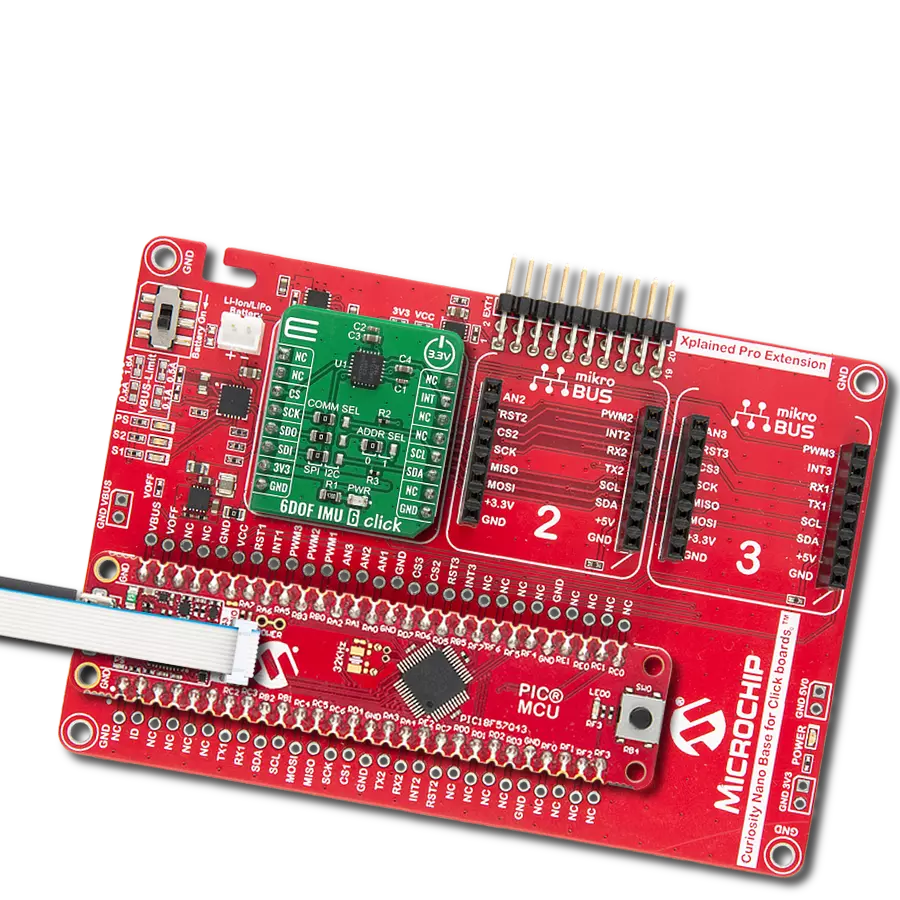

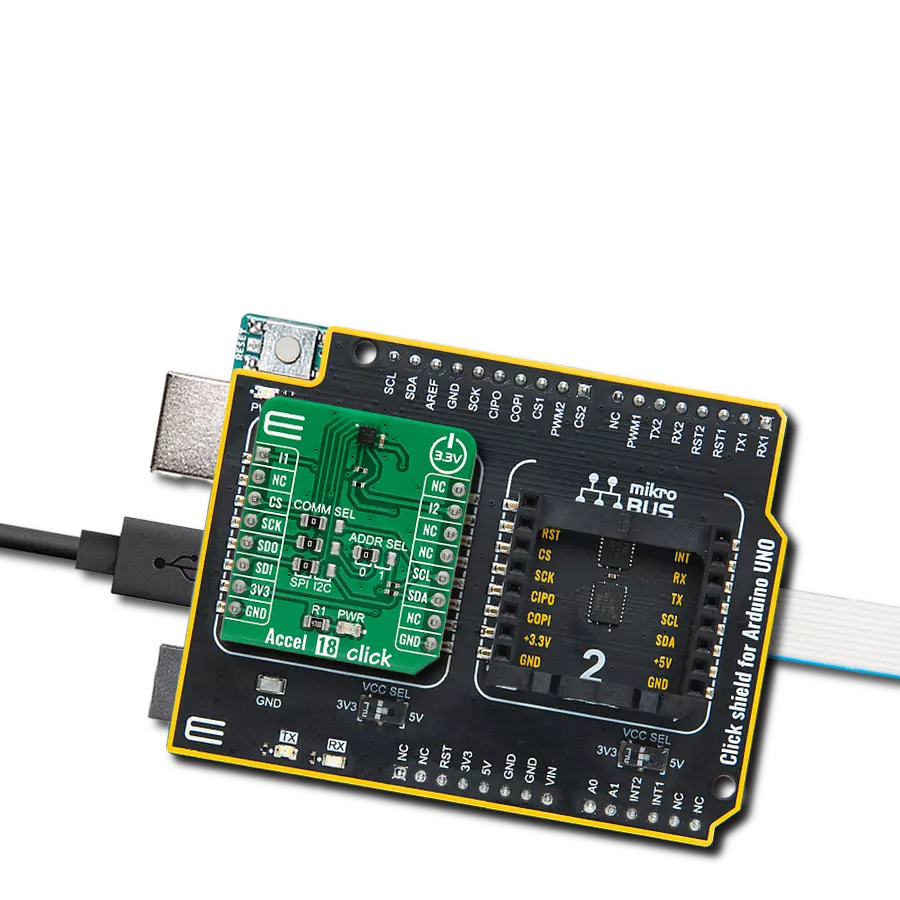

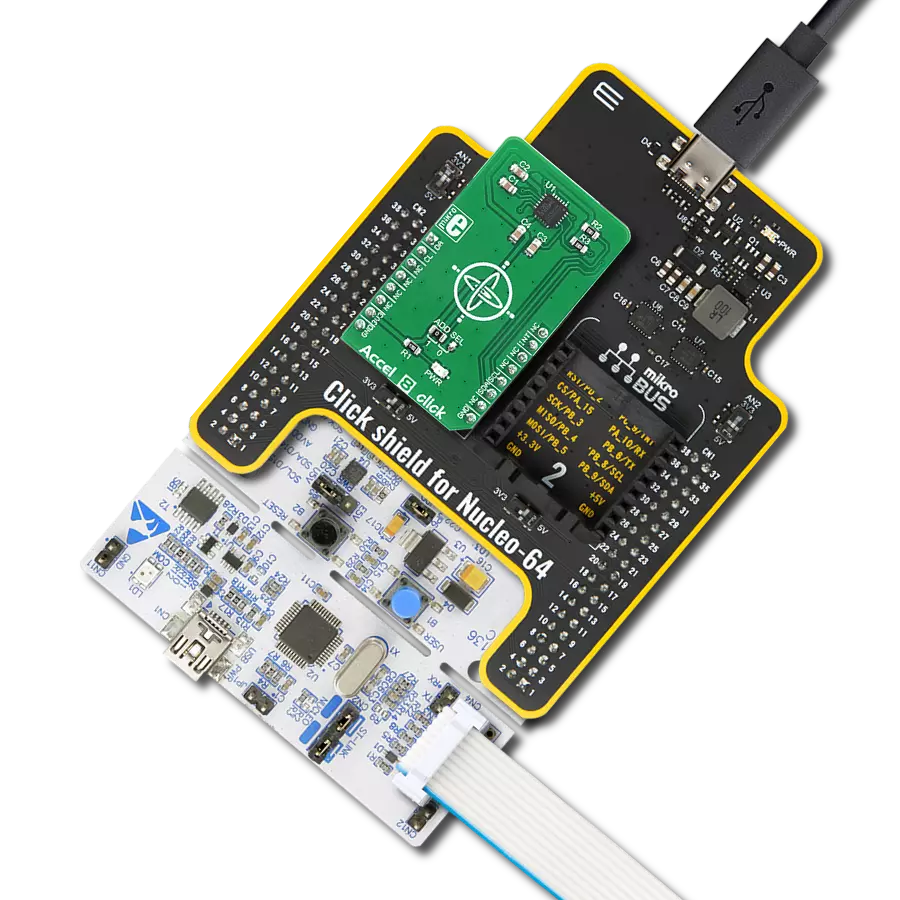

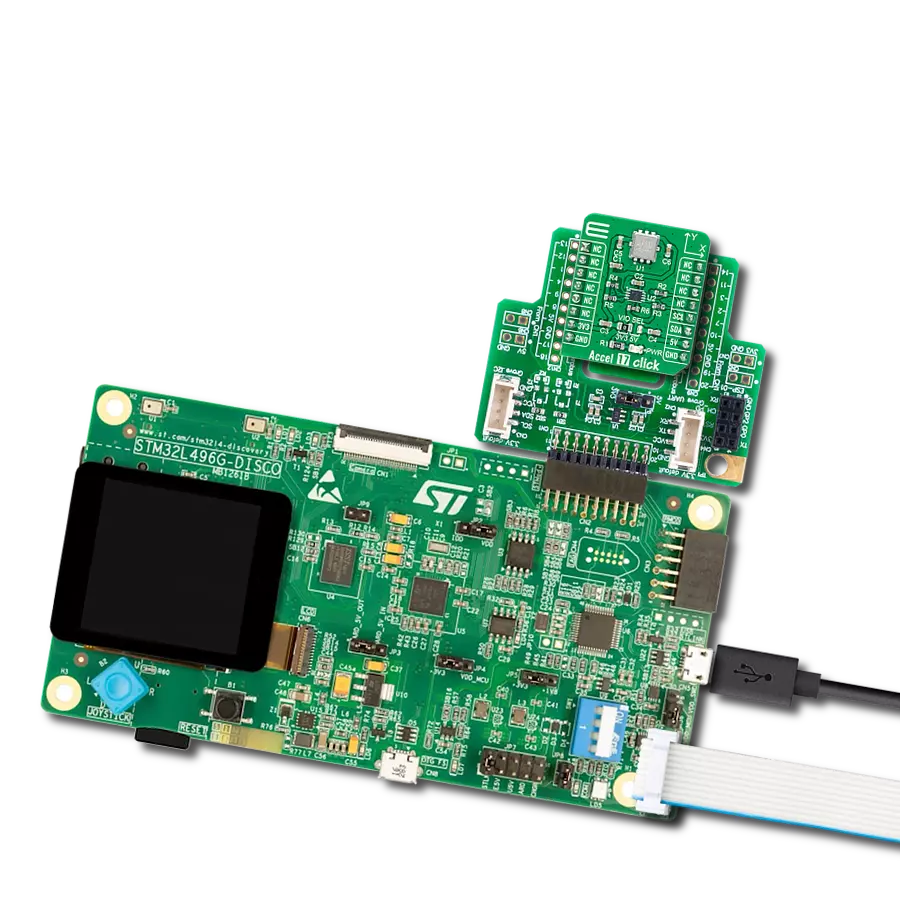

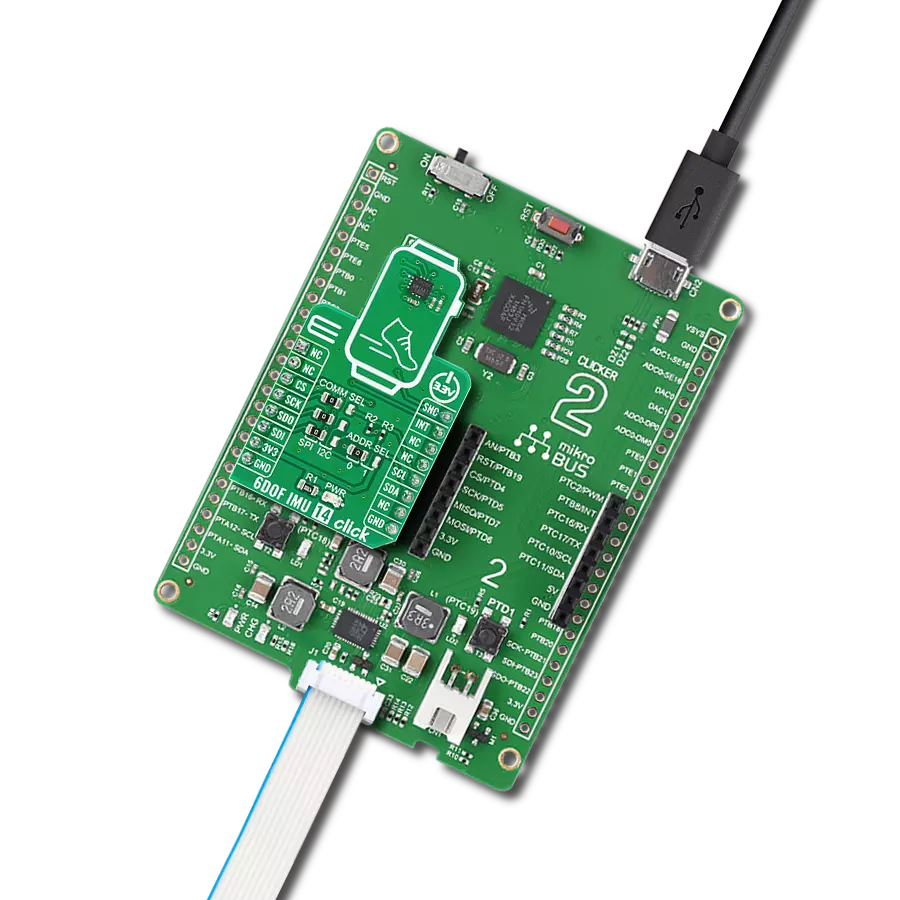

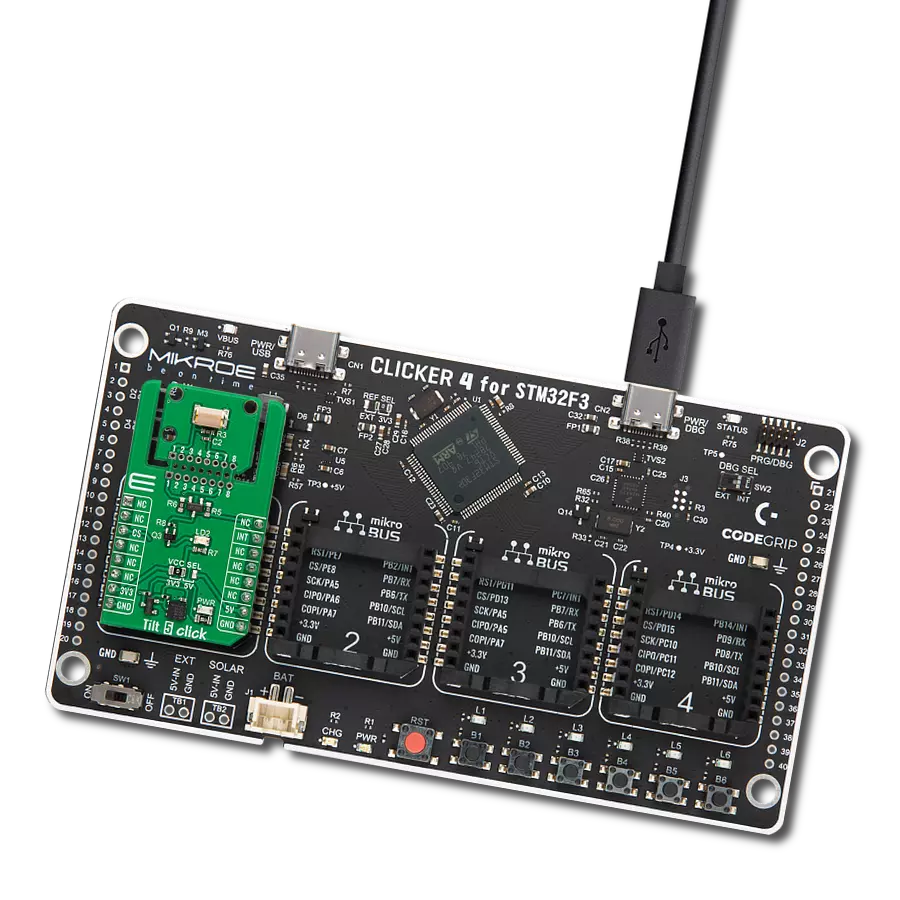

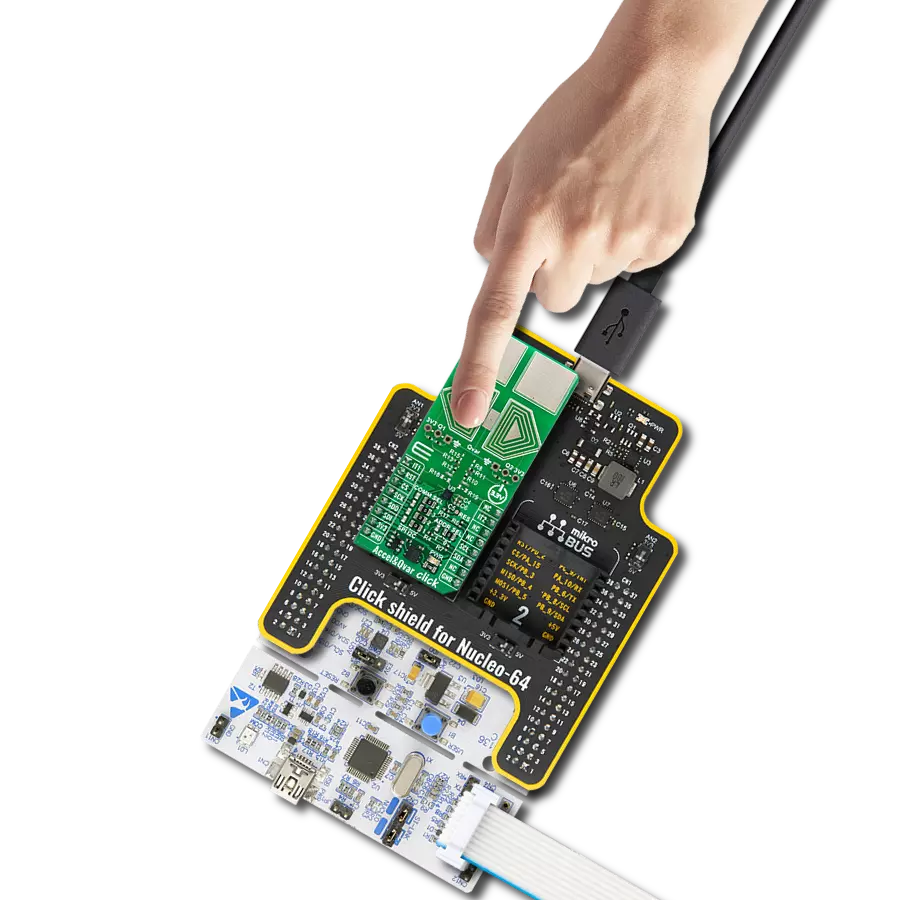

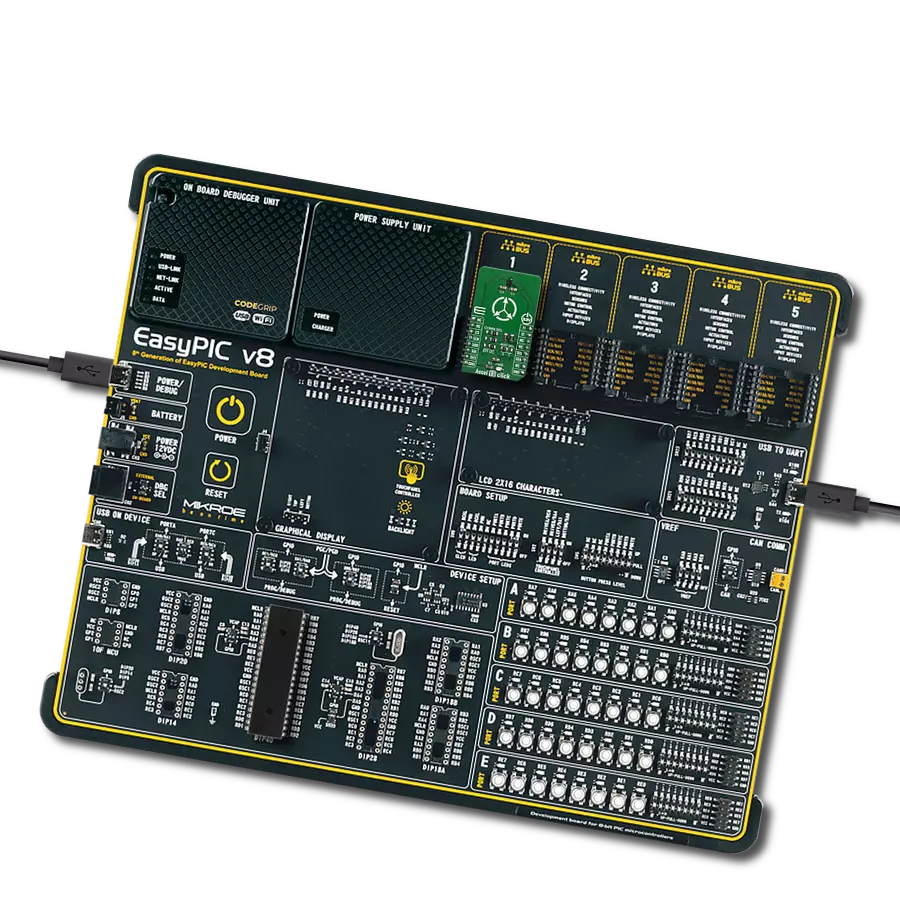

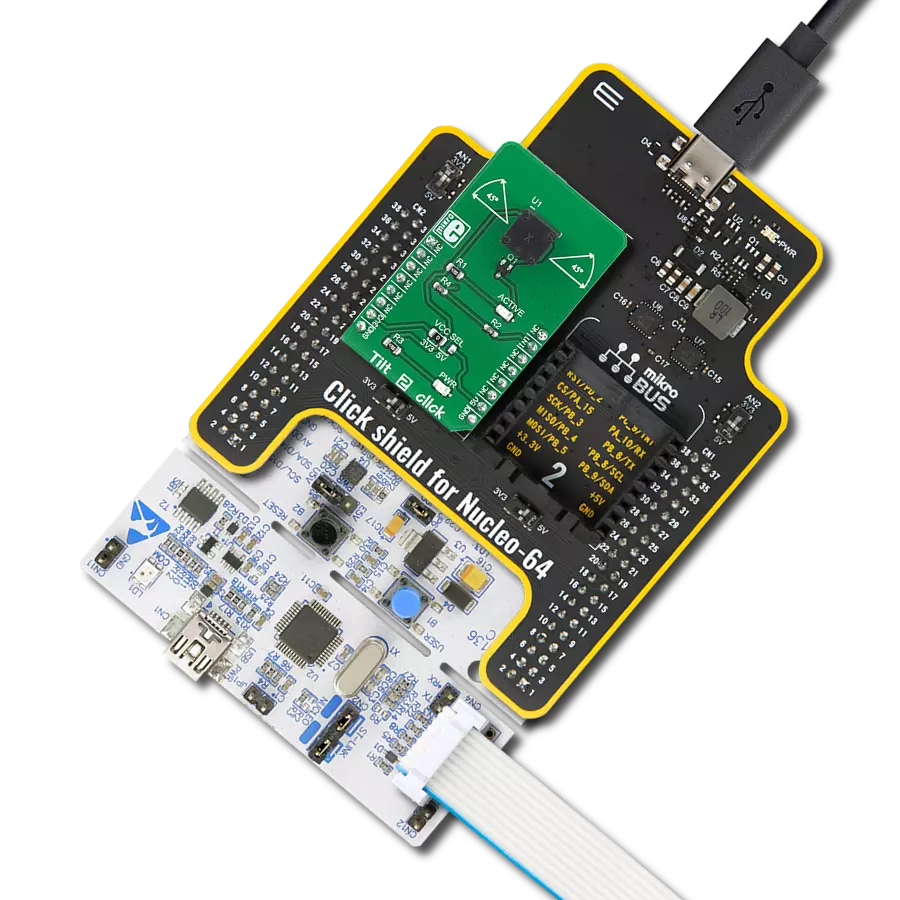

Development board

Clicker 2 for dsPIC33 is a compact starter development board that brings the flexibility of add-on Click boards™ to your favorite microcontroller, making it a perfect starter kit for implementing your ideas. It comes with an onboard 16-bit dsPIC33E family microcontroller, the dsPIC33EP512MU810 from Microchip, two mikroBUS™ sockets for Click board™ connectivity, a USB connector, LED indicators, buttons, a mikroProg programmer connector, and two 26-pin headers for interfacing with external electronics. Its compact design with clear and easily recognizable silkscreen markings allows you to build gadgets with unique

functionalities and features quickly. Each part of the Clicker 2 for dsPIC33 development kit contains the components necessary for the most efficient operation of the same board. In addition to the possibility of choosing the Clicker 2 for dsPIC33 programming method, using a USB HID mikroBootloader or an external mikroProg connector for dsPIC33 programmer, the Clicker 2 board also includes a clean and regulated power supply module for the development kit. It provides two ways of board-powering; through the USB Micro-B cable, where onboard voltage regulators provide the appropriate voltage levels to each

component on the board, or using a Li-Polymer battery via an onboard battery connector. All communication methods that mikroBUS™ itself supports are on this board, including the well-established mikroBUS™ socket, reset button, and several user-configurable buttons and LED indicators. Clicker 2 for dsPIC33 is an integral part of the Mikroe ecosystem, allowing you to create a new application in minutes. Natively supported by Mikroe software tools, it covers many aspects of prototyping thanks to a considerable number of different Click boards™ (over a thousand boards), the number of which is growing every day.

Microcontroller Overview

MCU Card / MCU

Architecture

dsPIC

MCU Memory (KB)

512

Silicon Vendor

Microchip

Pin count

100

RAM (Bytes)

53248

Used MCU Pins

mikroBUS™ mapper

Take a closer look

Click board™ Schematic

Step by step

Project assembly

Software Support

Library Description

This library contains API for Tilt 4 Click driver.

Key functions:

tilt4_read_int_state- This function reads the state of the interrupt pin of Tilt 4 Click.tilt4_set_led_state- This function sets the LED pin on the selected level level of Tilt 4 Click.

Open Source

Code example

The complete application code and a ready-to-use project are available through the NECTO Studio Package Manager for direct installation in the NECTO Studio. The application code can also be found on the MIKROE GitHub account.

/*!

* @file main.c

* @brief Tilt 4 Click Example.

*

* # Description

* This example demonstrates the use of Tilt 4 Click board.

*

* The demo application is composed of two sections :

*

* ## Application Init

* Initializes the driver and USB UART logger.

*

* ## Application Task

* As soon as the tilt switch state changes, it displays a corresponding message on the USB UART.

*

* @author Stefan Ilic

*

*/

#include "board.h"

#include "log.h"

#include "tilt4.h"

static tilt4_t tilt4; /**< Tilt 4 Click driver object. */

static log_t logger; /**< Logger object. */

static uint8_t tilt4_switch_state = TILT4_SWITCH_OFF;

void application_init ( void )

{

log_cfg_t log_cfg; /**< Logger config object. */

tilt4_cfg_t tilt4_cfg; /**< Click config object. */

/**

* Logger initialization.

* Default baud rate: 115200

* Default log level: LOG_LEVEL_DEBUG

* @note If USB_UART_RX and USB_UART_TX

* are defined as HAL_PIN_NC, you will

* need to define them manually for log to work.

* See @b LOG_MAP_USB_UART macro definition for detailed explanation.

*/

LOG_MAP_USB_UART( log_cfg );

log_init( &logger, &log_cfg );

log_info( &logger, " Application Init " );

// Click initialization.

tilt4_cfg_setup( &tilt4_cfg );

TILT4_MAP_MIKROBUS( tilt4_cfg, MIKROBUS_1 );

if ( DIGITAL_OUT_UNSUPPORTED_PIN == tilt4_init( &tilt4, &tilt4_cfg ) )

{

log_error( &logger, " Communication init." );

for ( ; ; );

}

log_info( &logger, " Application Task " );

}

void application_task ( void )

{

uint8_t state = tilt4_read_int_state ( &tilt4 );

if ( tilt4_switch_state != state )

{

tilt4_switch_state = state;

if ( TILT4_SWITCH_ON == tilt4_switch_state )

{

log_printf( &logger, " Tilt switch ON!\r\n\n" );

tilt4_set_led_state( &tilt4, TILT4_PIN_STATE_HIGH );

}

else

{

log_printf( &logger, " Tilt switch OFF!\r\n\n" );

tilt4_set_led_state( &tilt4, TILT4_PIN_STATE_LOW );

}

Delay_ms ( 500 );

}

}

int main ( void )

{

/* Do not remove this line or clock might not be set correctly. */

#ifdef PREINIT_SUPPORTED

preinit();

#endif

application_init( );

for ( ; ; )

{

application_task( );

}

return 0;

}

// ------------------------------------------------------------------------ END

Additional Support

Resources

Category:Motion