Achieve precise voltage control with smart DAC functionality for automotive applications

A

A

Hardware Overview

How does it work?

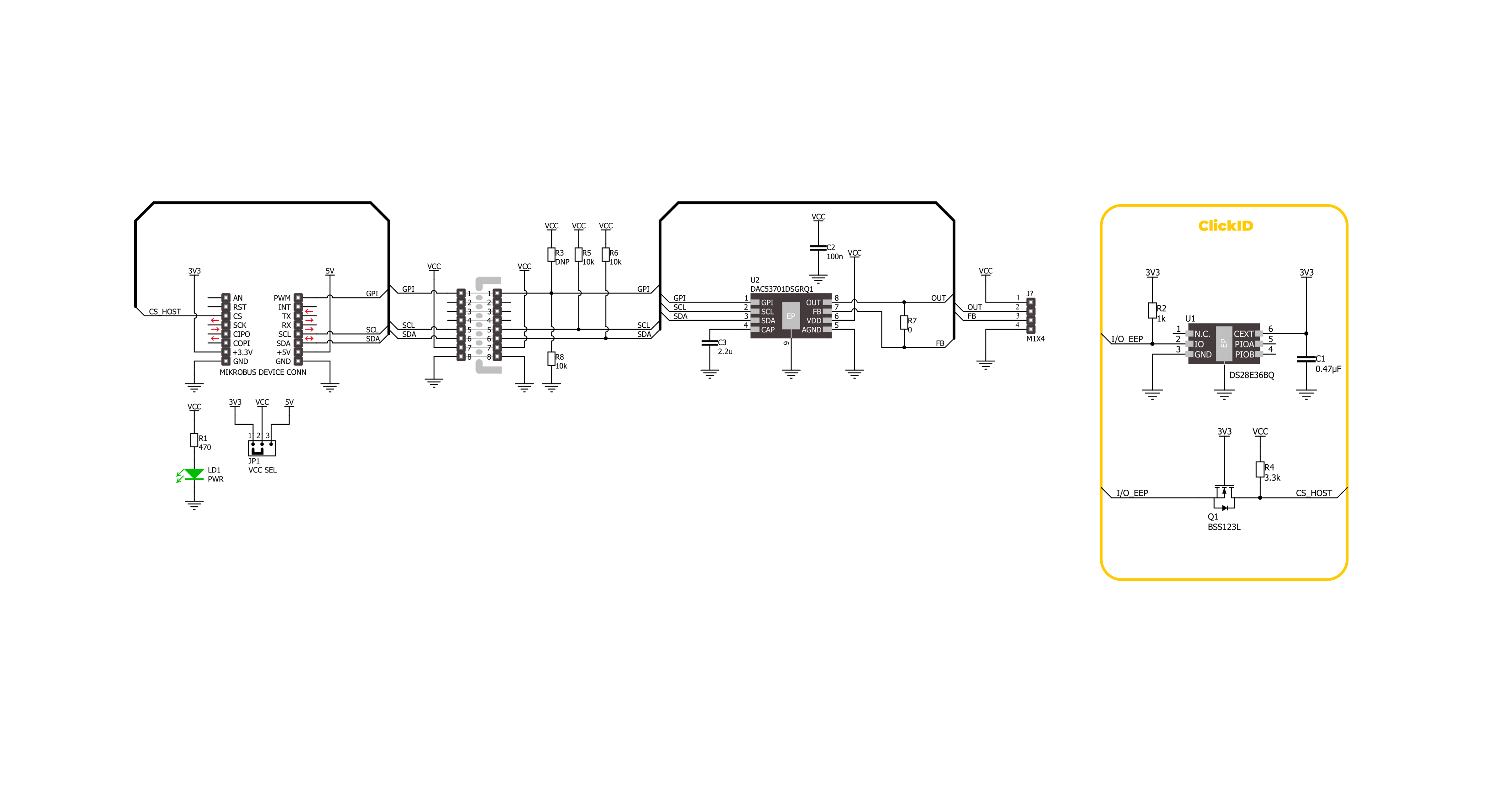

DAC 19 Click is based on the DAC53701-Q1, a 10-bit automotive-grade voltage-output digital-to-analog converter (DAC) from Texas Instruments, tailored for high-performance applications. This advanced DAC offers a range of smart features, making it ideal for control applications that demand enhanced performance without heavy reliance on software. Equipped with a force-sense output, a general-purpose input (GPI) function trigger, PWM output capability, and nonvolatile memory (NVM), the DAC53701-Q1 supports dynamic system performance and control functionality. This DAC can operate either with an internal reference or by using the power supply as a reference source, providing flexibility for different voltage needs. It supports a full-scale output range and integrates seamlessly with PMBus-compatible I2C communication, allowing it to interface efficiently with microcontrollers or other digital systems. The DAC53701-Q1's low power consumption also suits

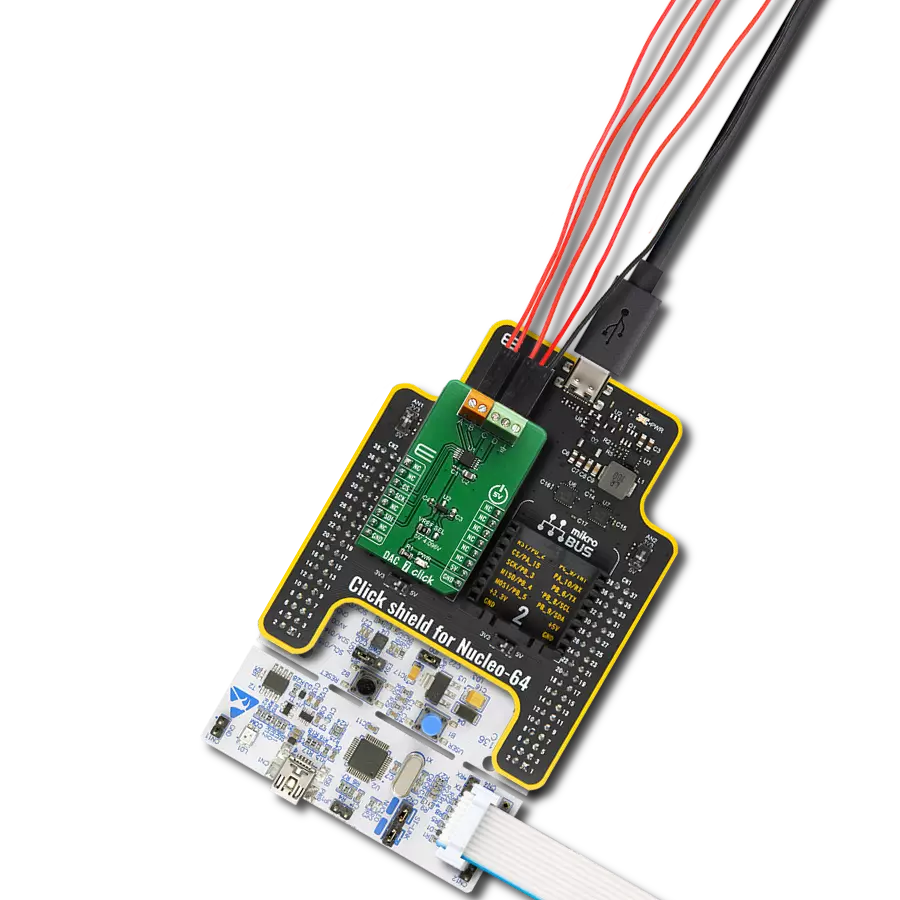

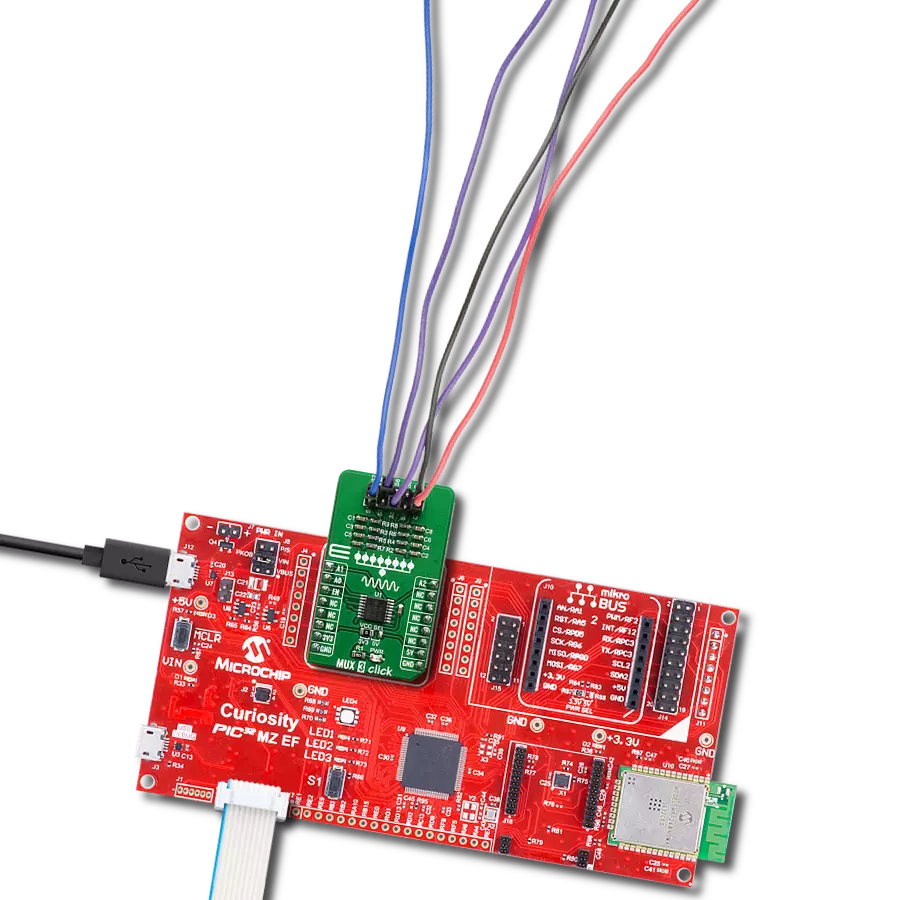

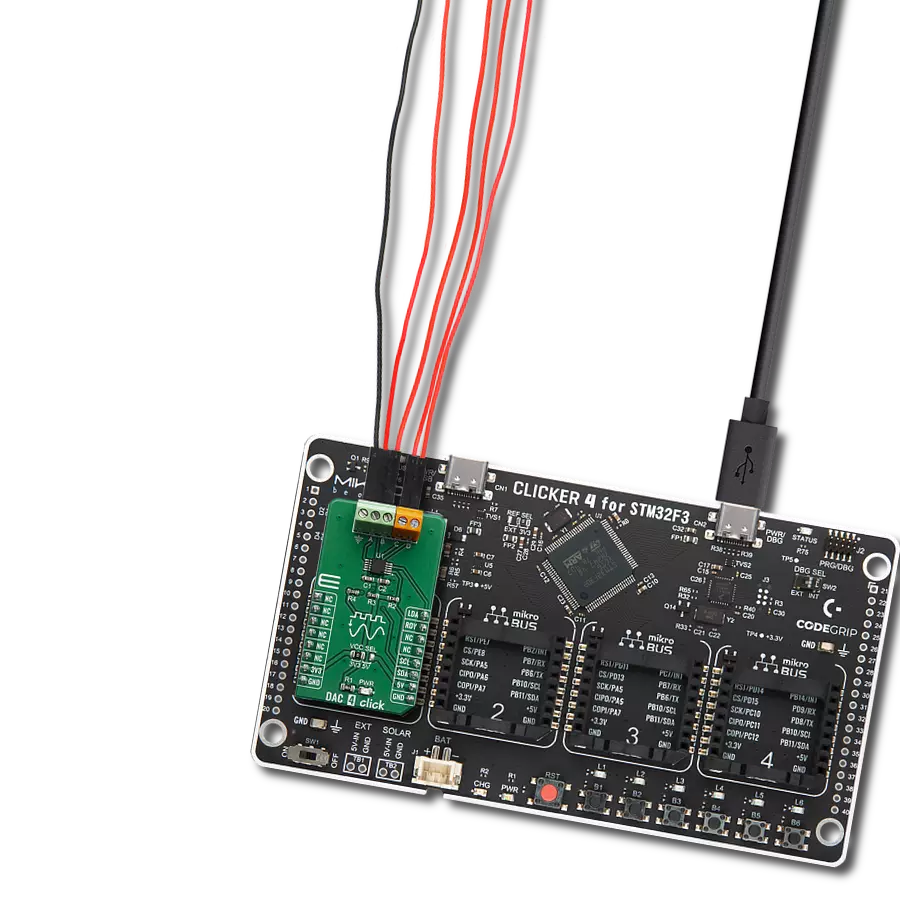

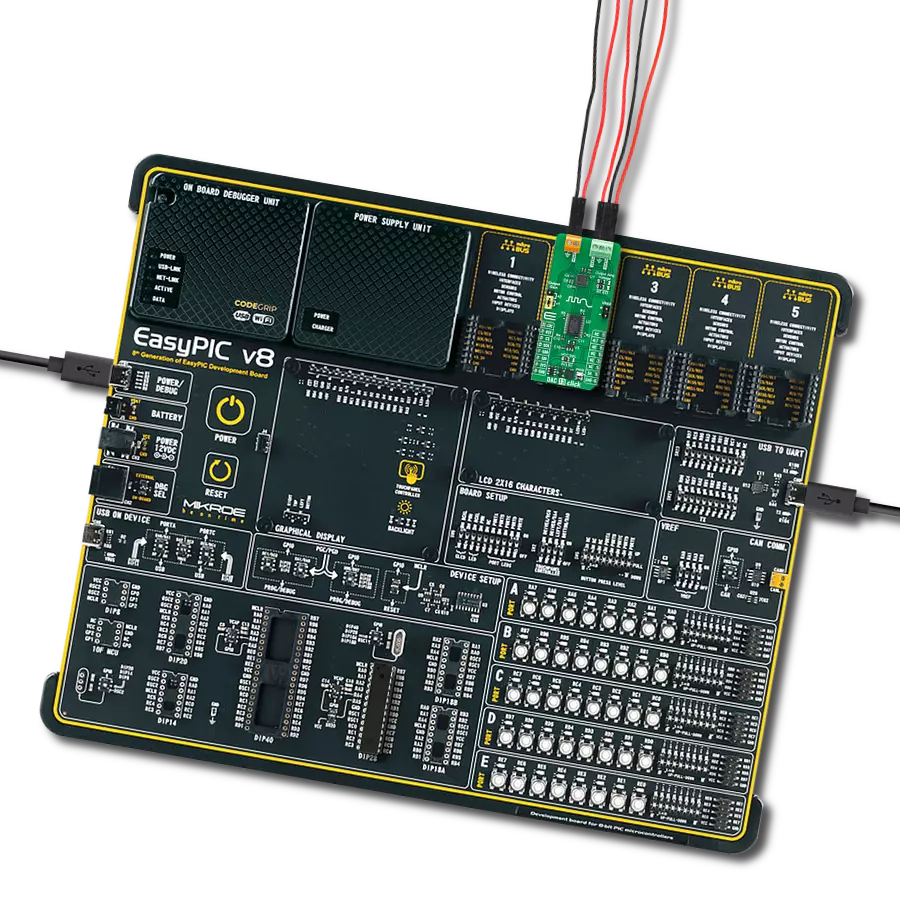

it, particularly for automotive applications, such as tail and brake light control, fade-in/fade-out effects for license plate lighting, and PWM-based control for interior lighting adjustments. This Click board™ is designed in a unique format supporting the newly introduced MIKROE feature called "Click Snap." Unlike the standardized version of Click boards, this feature allows the main sensor area to become movable by breaking the PCB, opening up many new possibilities for implementation. Thanks to the Snap feature, the DAC53701-Q1 can operate autonomously by accessing its signals directly on the pins marked 1-8. Additionally, the Snap part includes a specified and fixed screw hole position, enabling users to secure the Snap board in their desired location. As mentioned, the DAC 19 Click uses a standard 2-wire I2C interface to communicate with the host MCU, supporting Standard mode with up to 1MHz of frequency clock. It also provides a general-purpose input (GPI) pin

on the mikroBUS™ socket, which can be configured to trigger various functions thoroughly explained in the attached datasheet. The board features additional header pins connected to the DAC output, designed to provide a versatile force-sense capability. This feature allows the DAC to function as a programmable comparator and current sink, enabling precise control and flexibility in applications that require adaptable voltage monitoring and current control. These pins allow users to customize and expand the DAC's functionality according to specific needs. This Click board™ can operate with either 3.3V or 5V logic voltage levels selected via the VCC SEL jumper. This way, both 3.3V and 5V capable MCUs can use the communication lines properly. Also, this Click board™ comes equipped with a library containing easy-to-use functions and an example code that can be used as a reference for further development.

Features overview

Development board

Nucleo-64 with STM32G474R MCU offers a cost-effective and adaptable platform for developers to explore new ideas and prototype their designs. This board harnesses the versatility of the STM32 microcontroller, enabling users to select the optimal balance of performance and power consumption for their projects. It accommodates the STM32 microcontroller in the LQFP64 package and includes essential components such as a user LED, which doubles as an ARDUINO® signal, alongside user and reset push-buttons, and a 32.768kHz crystal oscillator for precise timing operations. Designed with expansion and flexibility in mind, the Nucleo-64 board features an ARDUINO® Uno V3 expansion connector and ST morpho extension pin

headers, granting complete access to the STM32's I/Os for comprehensive project integration. Power supply options are adaptable, supporting ST-LINK USB VBUS or external power sources, ensuring adaptability in various development environments. The board also has an on-board ST-LINK debugger/programmer with USB re-enumeration capability, simplifying the programming and debugging process. Moreover, the board is designed to simplify advanced development with its external SMPS for efficient Vcore logic supply, support for USB Device full speed or USB SNK/UFP full speed, and built-in cryptographic features, enhancing both the power efficiency and security of projects. Additional connectivity is

provided through dedicated connectors for external SMPS experimentation, a USB connector for the ST-LINK, and a MIPI® debug connector, expanding the possibilities for hardware interfacing and experimentation. Developers will find extensive support through comprehensive free software libraries and examples, courtesy of the STM32Cube MCU Package. This, combined with compatibility with a wide array of Integrated Development Environments (IDEs), including IAR Embedded Workbench®, MDK-ARM, and STM32CubeIDE, ensures a smooth and efficient development experience, allowing users to fully leverage the capabilities of the Nucleo-64 board in their projects.

Microcontroller Overview

MCU Card / MCU

Architecture

ARM Cortex-M4

MCU Memory (KB)

512

Silicon Vendor

STMicroelectronics

Pin count

64

RAM (Bytes)

128k

You complete me!

Accessories

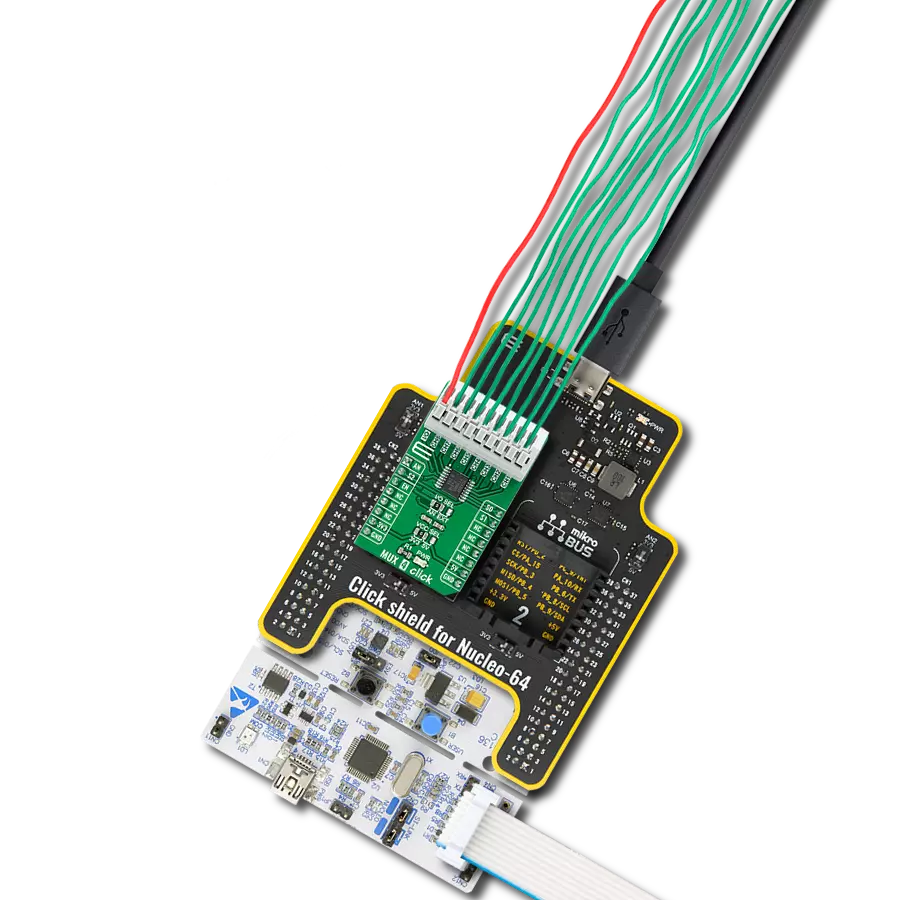

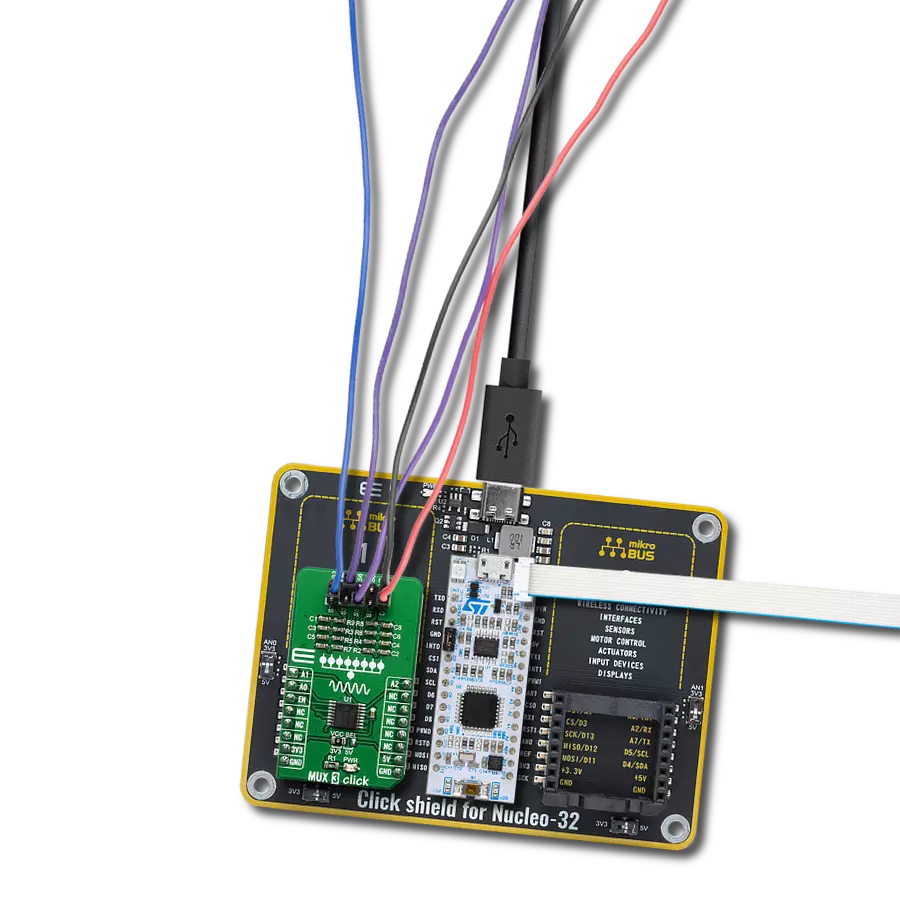

Click Shield for Nucleo-64 comes equipped with two proprietary mikroBUS™ sockets, allowing all the Click board™ devices to be interfaced with the STM32 Nucleo-64 board with no effort. This way, Mikroe allows its users to add any functionality from our ever-growing range of Click boards™, such as WiFi, GSM, GPS, Bluetooth, ZigBee, environmental sensors, LEDs, speech recognition, motor control, movement sensors, and many more. More than 1537 Click boards™, which can be stacked and integrated, are at your disposal. The STM32 Nucleo-64 boards are based on the microcontrollers in 64-pin packages, a 32-bit MCU with an ARM Cortex M4 processor operating at 84MHz, 512Kb Flash, and 96KB SRAM, divided into two regions where the top section represents the ST-Link/V2 debugger and programmer while the bottom section of the board is an actual development board. These boards are controlled and powered conveniently through a USB connection to program and efficiently debug the Nucleo-64 board out of the box, with an additional USB cable connected to the USB mini port on the board. Most of the STM32 microcontroller pins are brought to the IO pins on the left and right edge of the board, which are then connected to two existing mikroBUS™ sockets. This Click Shield also has several switches that perform functions such as selecting the logic levels of analog signals on mikroBUS™ sockets and selecting logic voltage levels of the mikroBUS™ sockets themselves. Besides, the user is offered the possibility of using any Click board™ with the help of existing bidirectional level-shifting voltage translators, regardless of whether the Click board™ operates at a 3.3V or 5V logic voltage level. Once you connect the STM32 Nucleo-64 board with our Click Shield for Nucleo-64, you can access hundreds of Click boards™, working with 3.3V or 5V logic voltage levels.

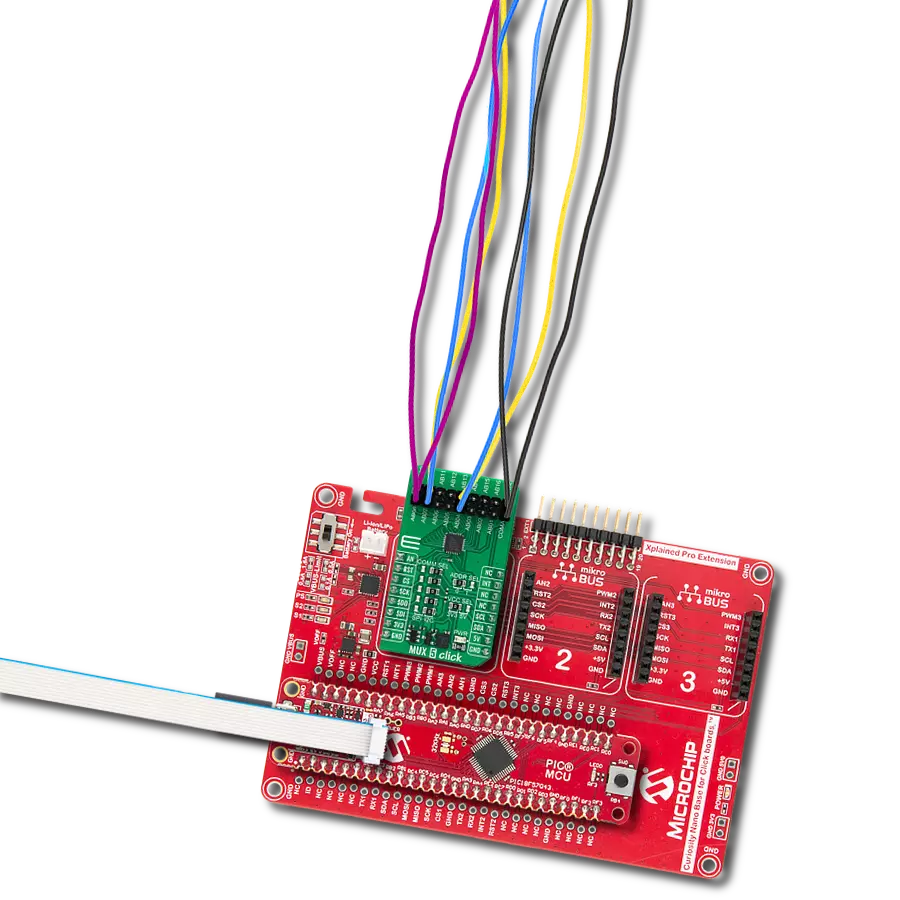

Wire Jumpers Male to Female (15 cm length, 10pcs) is a set of high-quality jumper wires designed for easy prototyping and testing. Each wire in the set is 15cm long, with male connectors on one end and female on other, allowing an easy connection between components on breadboards or other electronic projects. The set includes ten wires in different colors, providing clear identification and organization in your circuit. These wire jumpers are ideal for DIY projects, setups, and other electronic applications where quick, reliable connections are required.

Used MCU Pins

mikroBUS™ mapper

Take a closer look

Click board™ Schematic

Step by step

Project assembly

Software Support

Library Description

This library contains API for DAC 19 Click driver.

Key functions:

dac19_set_voltage- This function sets the output voltage depending on the vref value defined by the VCC SEL on-board jumper. VREF and Voltage values can be either in Volts or Milivolts.dac19_set_value- This function sets the DAC DATA register to a desired value.dac19_set_voltage_int_vref- This function sets the output voltage with the internal reference enabled.

Open Source

Code example

The complete application code and a ready-to-use project are available through the NECTO Studio Package Manager for direct installation in the NECTO Studio. The application code can also be found on the MIKROE GitHub account.

/*!

* @file main.c

* @brief DAC 19 Click example

*

* # Description

* This example demonstrates the use of DAC 19 Click board by changing the output voltage level.

*

* The demo application is composed of two sections :

*

* ## Application Init

* Initializes the driver, checks the communication by reading and verifying the device ID,

* and enables the DAC output.

*

* ## Application Task

* Changes the output voltage every 2 seconds and logs the voltage value on the USB UART.

* It will go through the entire voltage range for the step number defined below.

*

* @note

* Measure the voltage at VCC_SEL jumper and adjust the reference voltage value below for better accuracy.

*

* @author Stefan Filipovic

*

*/

#include "board.h"

#include "log.h"

#include "dac19.h"

#define REFERENCE_VOLTAGE_MV 3300 // The reference voltage defined by the VCC_SEL on-board jumper.

#define NUMBER_OF_STEPS 20 // The number of steps by which we will divide the entire voltage range.

static dac19_t dac19;

static log_t logger;

void application_init ( void )

{

log_cfg_t log_cfg; /**< Logger config object. */

dac19_cfg_t dac19_cfg; /**< Click config object. */

/**

* Logger initialization.

* Default baud rate: 115200

* Default log level: LOG_LEVEL_DEBUG

* @note If USB_UART_RX and USB_UART_TX

* are defined as HAL_PIN_NC, you will

* need to define them manually for log to work.

* See @b LOG_MAP_USB_UART macro definition for detailed explanation.

*/

LOG_MAP_USB_UART( log_cfg );

log_init( &logger, &log_cfg );

log_info( &logger, " Application Init " );

// Click initialization.

dac19_cfg_setup( &dac19_cfg );

DAC19_MAP_MIKROBUS( dac19_cfg, MIKROBUS_1 );

if ( I2C_MASTER_ERROR == dac19_init( &dac19, &dac19_cfg ) )

{

log_error( &logger, " Communication init." );

for ( ; ; );

}

if ( DAC19_ERROR == dac19_default_cfg ( &dac19 ) )

{

log_error( &logger, " Default configuration." );

for ( ; ; );

}

log_info( &logger, " Application Task " );

}

void application_task ( void )

{

uint16_t step = REFERENCE_VOLTAGE_MV / NUMBER_OF_STEPS;

uint16_t output_voltage = step;

for ( uint8_t cnt = 0; cnt < NUMBER_OF_STEPS; cnt++ )

{

if ( DAC19_OK == dac19_set_voltage ( &dac19, REFERENCE_VOLTAGE_MV, output_voltage ) )

{

log_printf( &logger, " VOUT: %u mV\r\n", output_voltage );

}

output_voltage += step;

Delay_ms ( 1000 );

Delay_ms ( 1000 );

}

}

int main ( void )

{

/* Do not remove this line or clock might not be set correctly. */

#ifdef PREINIT_SUPPORTED

preinit();

#endif

application_init( );

for ( ; ; )

{

application_task( );

}

return 0;

}

// ------------------------------------------------------------------------ END

Additional Support

Resources

Category:DAC