Step into a world of seamless signal routing with our CMOS analog multiplexing solution. Engineered for precision and flexibility, it empowers you to channel and manage various signals with efficiency and accuracy

A

A

Hardware Overview

How does it work?

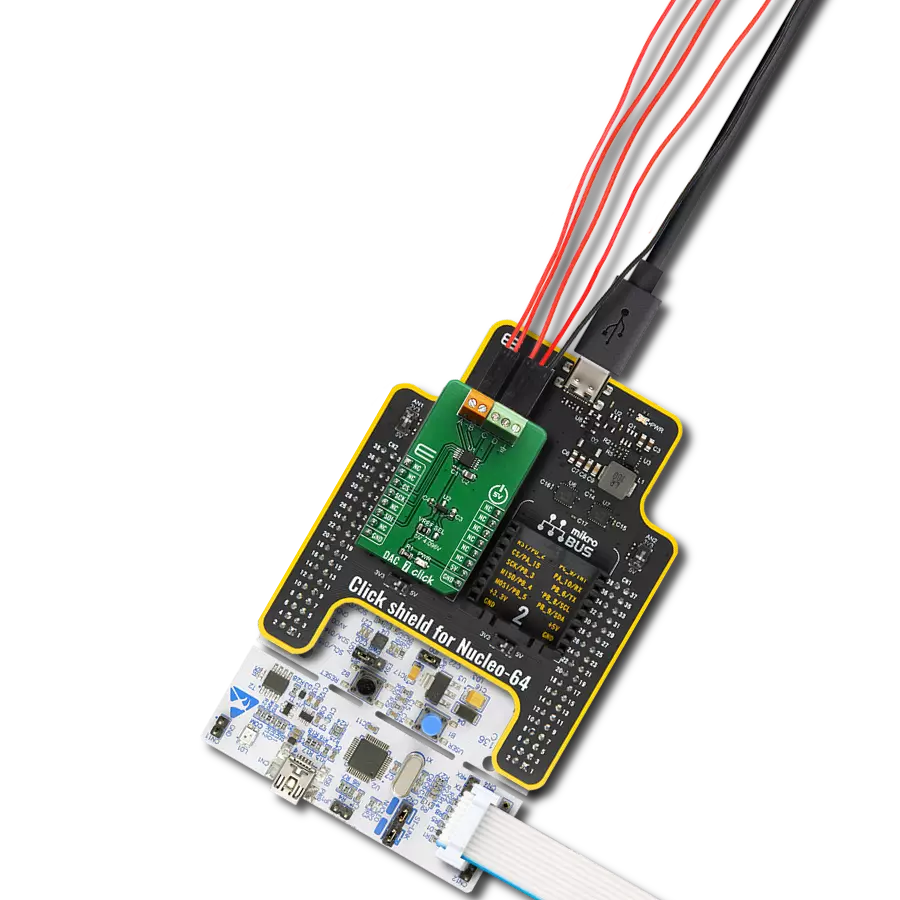

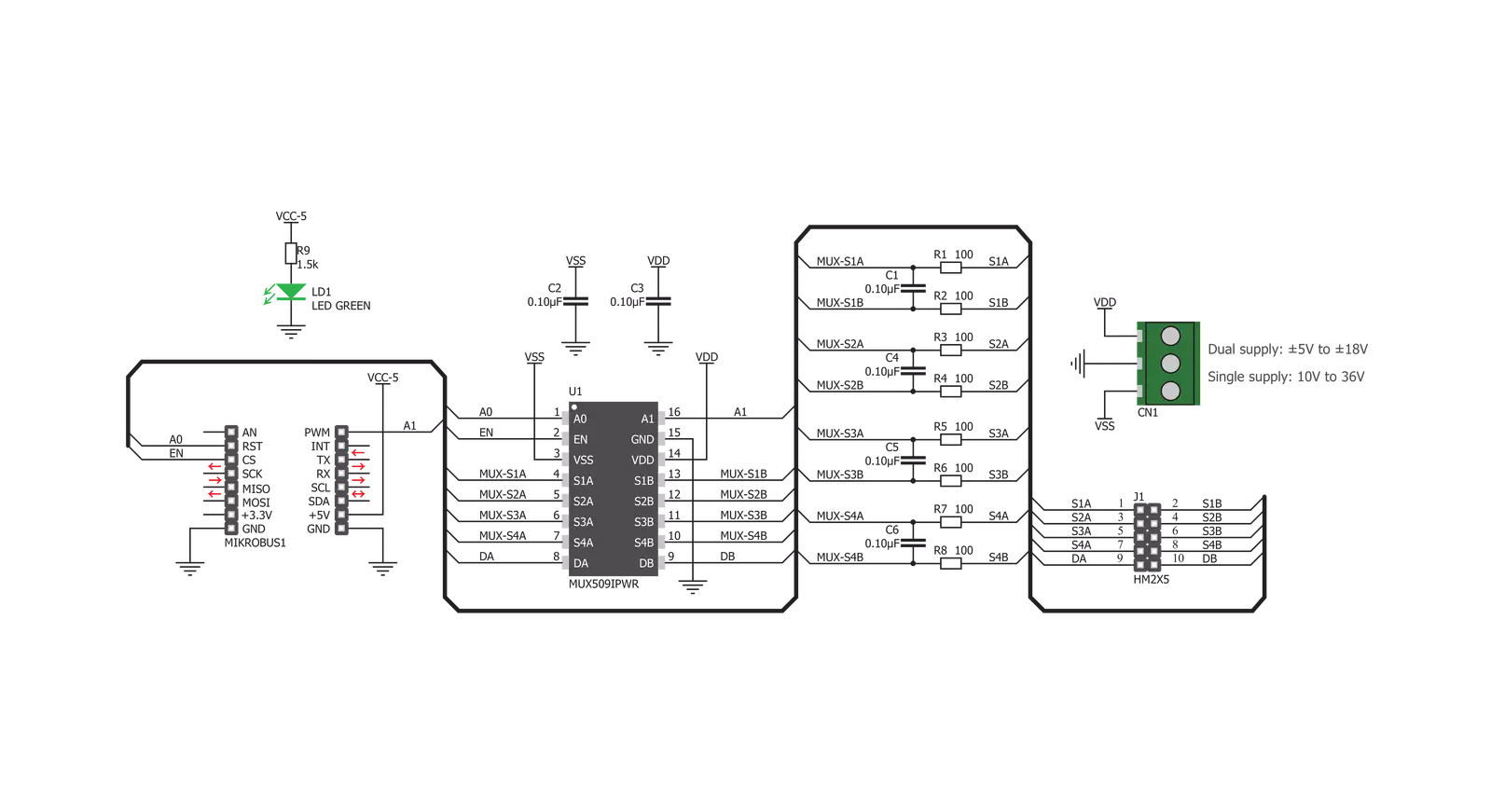

MUX Click is based on the MUX509, a precise analog multiplexing IC from Texas Instruments. The MUX509 can be used with a wide range of power supplies. It can handle dual and single power supplies and symmetrical and non-symmetrical ones. This allows it to be used in a wide range of different applications. Another property of the MUX509 is that it has dual inputs and dual output. Three control pins switch one of four input pairs to a single output pair. Control pins labeled A0 and A1 are routed to the mikroBUS™ and can be operated by both 3.3V and 5V MCUs. The third control pin, labeled as EN pin, is used to enable the output when set to a HIGH logic level (active HIGH). A0 and A1 pins are routed to the RST and PWM pins of the mikroBUS™, respectively, while the EN pin is routed to the CS pin on the mikroBUS™. The MUX509 IC is targeted toward working with differential signals rather than single-ended inputs. Each input comprises two pins: SNA, and SNB, where N represents the channel number from 1 to 4. When a specific

channel is selected (N), the SNA and SNB pins will be routed to the DA and DB output pins. Each signal pair is equipped with a 100nF parallel capacitor and 100Ω series resistance for improved stability. The input and the output signal pins are routed to the standard 2.54mm pitch 2x5 pins header on the Click board™. The ultra-low leakage current ensures no signal interference from the inputs not selected by the A0 and A1 pins. Low crosstalk also ensures that the signal on one channel remains clean of interferences caused by other channels. The break-before-make switching action prevents any two inputs from being switched simultaneously at the output. This ensures the reliable operation of the IC and the Click board™ itself. MUX click does not use the power from the mikroBUS™ power rails, except for the LED indicator. Instead, a three-pole screw terminal connects an external power supply. Considering the minimum input voltage of 10V or ±5V, a power supply should be connected to this terminal before operating the Click board™.

Depending on the type of the used power supply (single supply or symmetrical/dual supply), it should be connected to the power supply input terminal, accordingly: GND is the reference ground connection, VSS is the negative voltage connection terminal (GND if a single power supply is used), and VDD is the positive voltage connection terminal. The input and output signals can be connected via the 2x5 pins header. As mentioned, the MUX509 IC supports rail-to-rail operation, supporting input and output signals ranging from VSS (or GND) up to VDD. Independent power supply input allows the user to work with a wide range of signal amplitudes, depending on the application requirements, as long as the power supply stays within limits. More information about the MUX509 can be found in the attached datasheet. However, the Click board™ comes equipped with a library that contains easy-to-use functions and a usage example that may be used as a reference for the development.

Features overview

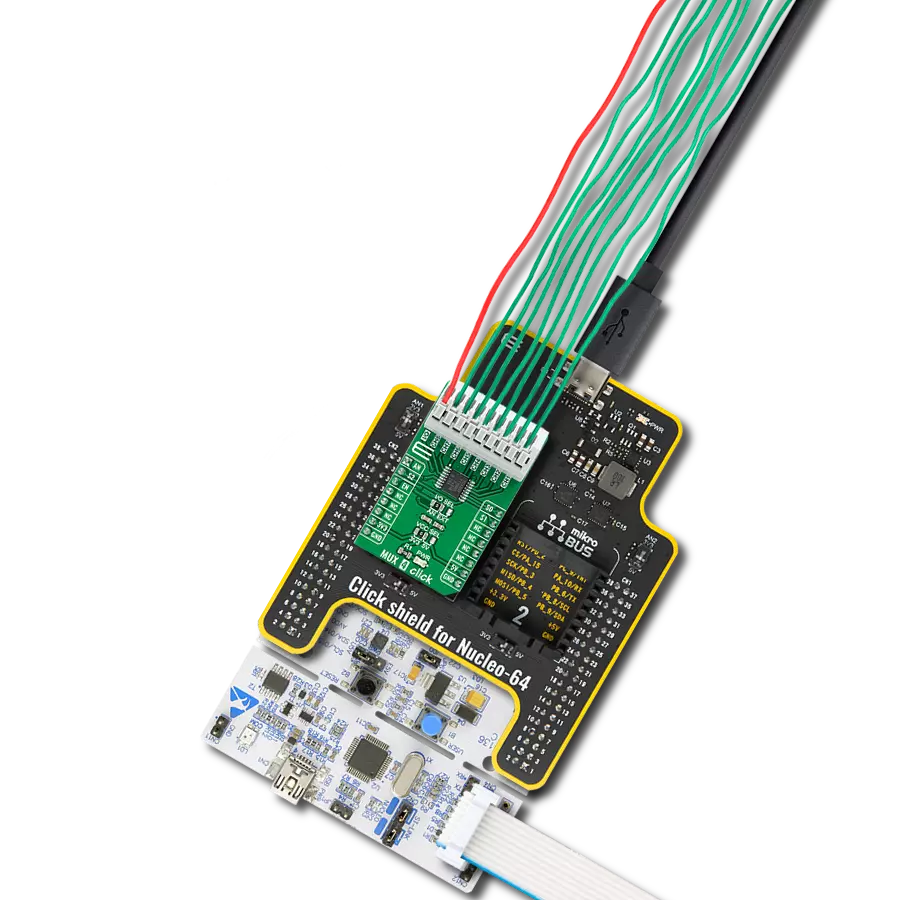

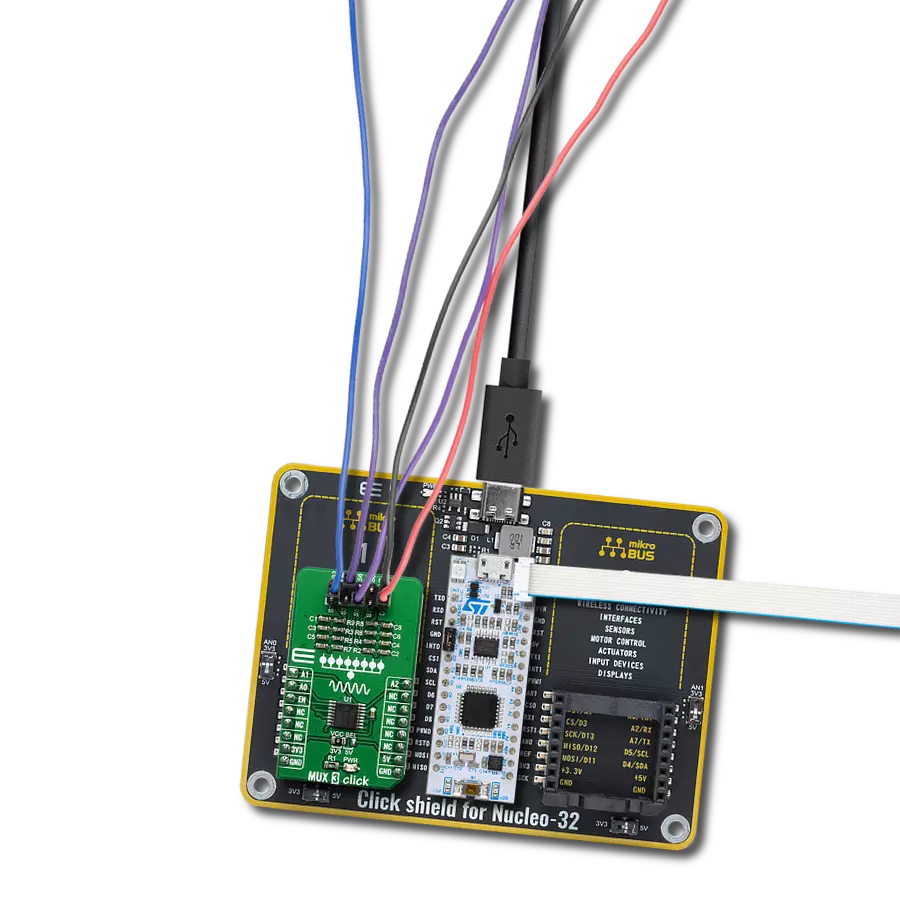

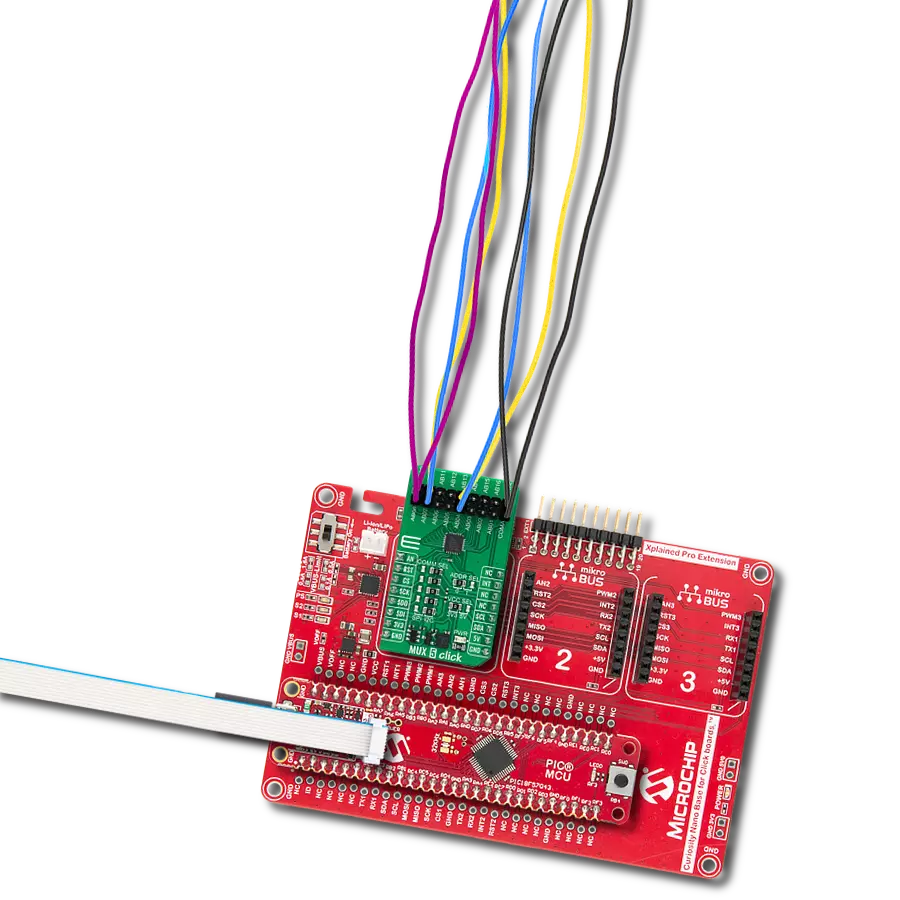

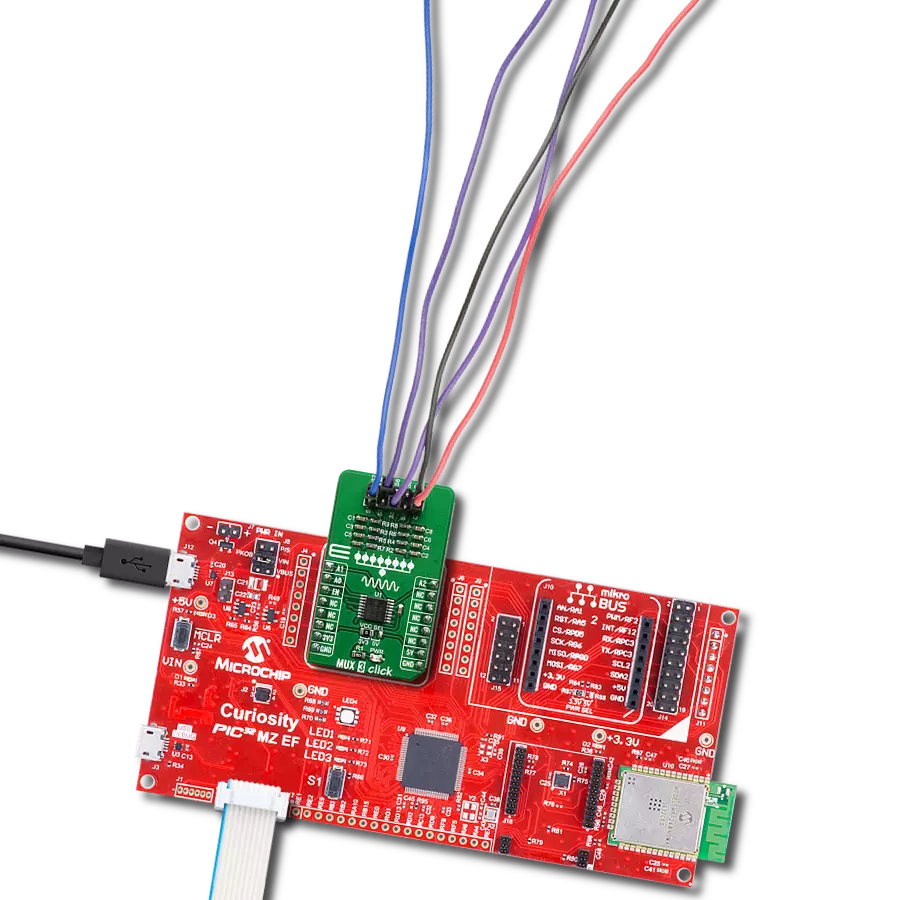

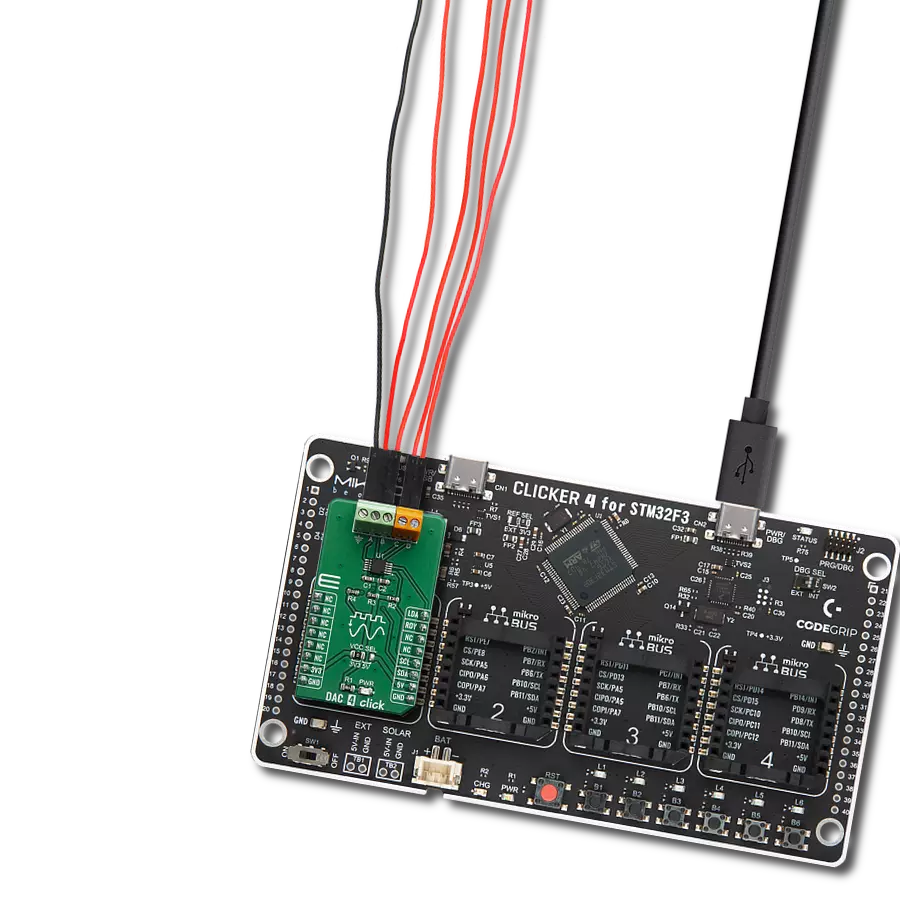

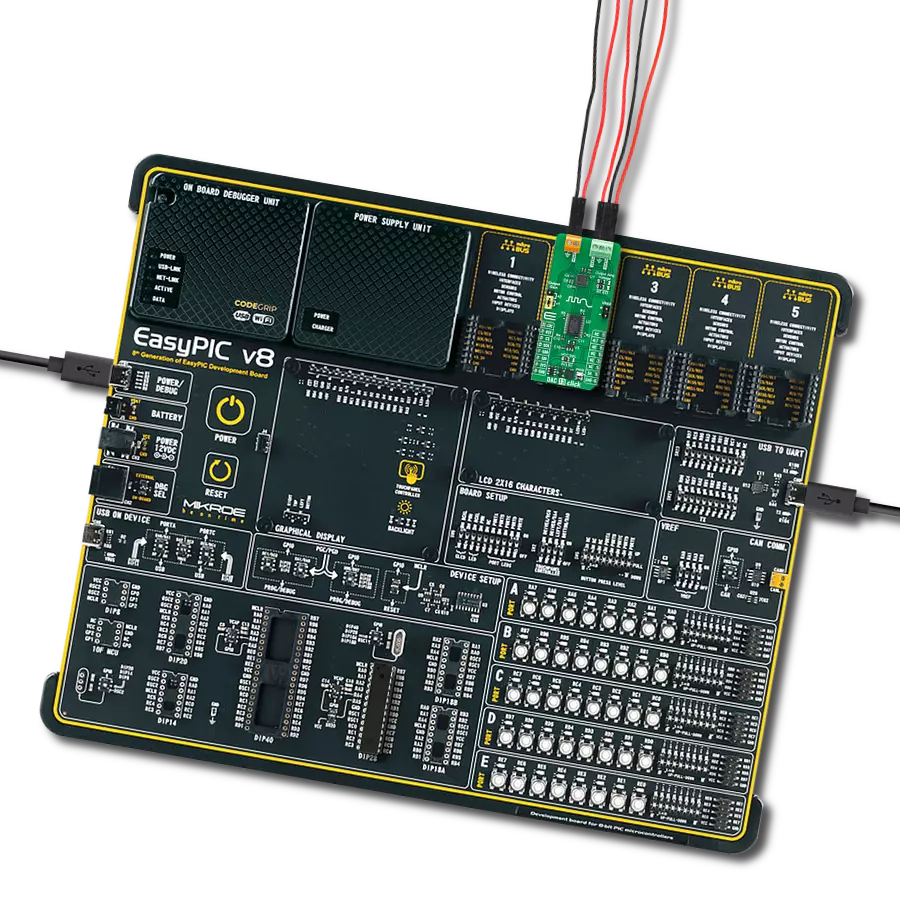

Development board

Clicker 2 for Kinetis is a compact starter development board that brings the flexibility of add-on Click boards™ to your favorite microcontroller, making it a perfect starter kit for implementing your ideas. It comes with an onboard 32-bit ARM Cortex-M4F microcontroller, the MK64FN1M0VDC12 from NXP Semiconductors, two mikroBUS™ sockets for Click board™ connectivity, a USB connector, LED indicators, buttons, a JTAG programmer connector, and two 26-pin headers for interfacing with external electronics. Its compact design with clear and easily recognizable silkscreen markings allows you to build gadgets with unique functionalities and

features quickly. Each part of the Clicker 2 for Kinetis development kit contains the components necessary for the most efficient operation of the same board. In addition to the possibility of choosing the Clicker 2 for Kinetis programming method, using a USB HID mikroBootloader or an external mikroProg connector for Kinetis programmer, the Clicker 2 board also includes a clean and regulated power supply module for the development kit. It provides two ways of board-powering; through the USB Micro-B cable, where onboard voltage regulators provide the appropriate voltage levels to each component on the board, or

using a Li-Polymer battery via an onboard battery connector. All communication methods that mikroBUS™ itself supports are on this board, including the well-established mikroBUS™ socket, reset button, and several user-configurable buttons and LED indicators. Clicker 2 for Kinetis is an integral part of the Mikroe ecosystem, allowing you to create a new application in minutes. Natively supported by Mikroe software tools, it covers many aspects of prototyping thanks to a considerable number of different Click boards™ (over a thousand boards), the number of which is growing every day.

Microcontroller Overview

MCU Card / MCU

Architecture

ARM Cortex-M4

MCU Memory (KB)

1024

Silicon Vendor

NXP

Pin count

121

RAM (Bytes)

262144

Used MCU Pins

mikroBUS™ mapper

Take a closer look

Click board™ Schematic

Step by step

Project assembly

Software Support

Library Description

This library contains API for MUX Click driver.

Key functions:

mux_active_mux_channel- Select active MUX channelmux_device_disable- Disable MUX device functionmux_device_enable- Enable MUX device function

Open Source

Code example

The complete application code and a ready-to-use project are available through the NECTO Studio Package Manager for direct installation in the NECTO Studio. The application code can also be found on the MIKROE GitHub account.

/*!

* \file

* \brief MUX Click example

*

* # Description

* Sets the current active channel. Changes the channel every 5 sec.

*

* The demo application is composed of two sections :

*

* ## Application Init

* Initializes GPIO module and sets RST, CS and PWM pins as OUTPUT.

*

* ## Application Task

* Changes currently active channel every 5 sec.

*

* \author Luka Filipovic

*

*/

// ------------------------------------------------------------------- INCLUDES

#include "board.h"

#include "log.h"

#include "mux.h"

// ------------------------------------------------------------------ VARIABLES

static mux_t mux;

static log_t logger;

// ------------------------------------------------------ APPLICATION FUNCTIONS

void application_init ( void )

{

log_cfg_t log_cfg;

mux_cfg_t cfg;

/**

* Logger initialization.

* Default baud rate: 115200

* Default log level: LOG_LEVEL_DEBUG

* @note If USB_UART_RX and USB_UART_TX

* are defined as HAL_PIN_NC, you will

* need to define them manually for log to work.

* See @b LOG_MAP_USB_UART macro definition for detailed explanation.

*/

LOG_MAP_USB_UART( log_cfg );

log_init( &logger, &log_cfg );

log_info(&logger, "---- Application Init ----");

// Click initialization.

mux_cfg_setup( &cfg );

MUX_MAP_MIKROBUS( cfg, MIKROBUS_1 );

mux_init( &mux, &cfg );

Delay_ms ( 100 );

log_printf( &logger, " MUX Click\r\n" );

log_printf( &logger, "------------------------\r\n" );

mux_device_enable( &mux );

log_printf( &logger, " Enable MUX device\r\n" );

log_printf( &logger, "------------------------\r\n" );

Delay_ms ( 100 );

}

void application_task ( void )

{

uint16_t n_cnt;

for ( n_cnt = MUX_CHANNEL_1A_AND_1B; n_cnt < MUX_CHANNEL_END; n_cnt++ )

{

log_printf( &logger, " CHANNEL S%u\r\n", n_cnt );

log_printf( &logger, "------------------------\r\n" );

mux_active_mux_channel( &mux, n_cnt );

Delay_ms ( 1000 );

Delay_ms ( 1000 );

Delay_ms ( 1000 );

Delay_ms ( 1000 );

Delay_ms ( 1000 );

}

}

int main ( void )

{

/* Do not remove this line or clock might not be set correctly. */

#ifdef PREINIT_SUPPORTED

preinit();

#endif

application_init( );

for ( ; ; )

{

application_task( );

}

return 0;

}

// ------------------------------------------------------------------------ END