Create displays that give you quick, easy-to-understand information about various things, like how loud the music is or how much power a device uses

A

A

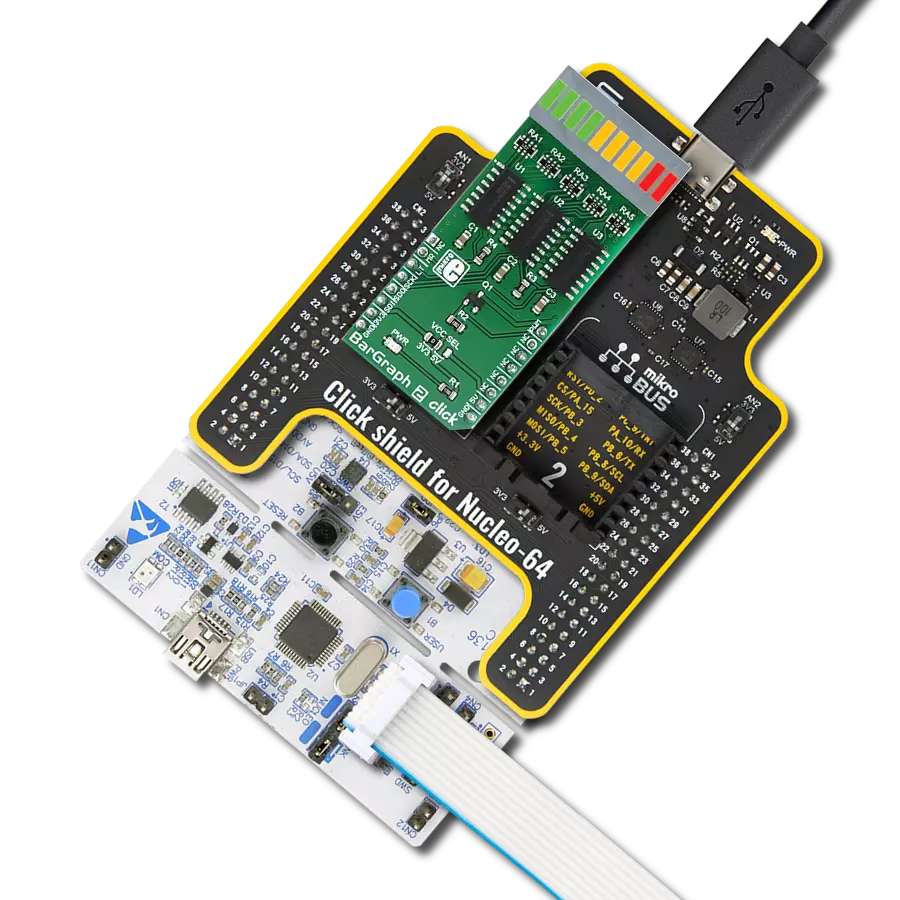

Hardware Overview

How does it work?

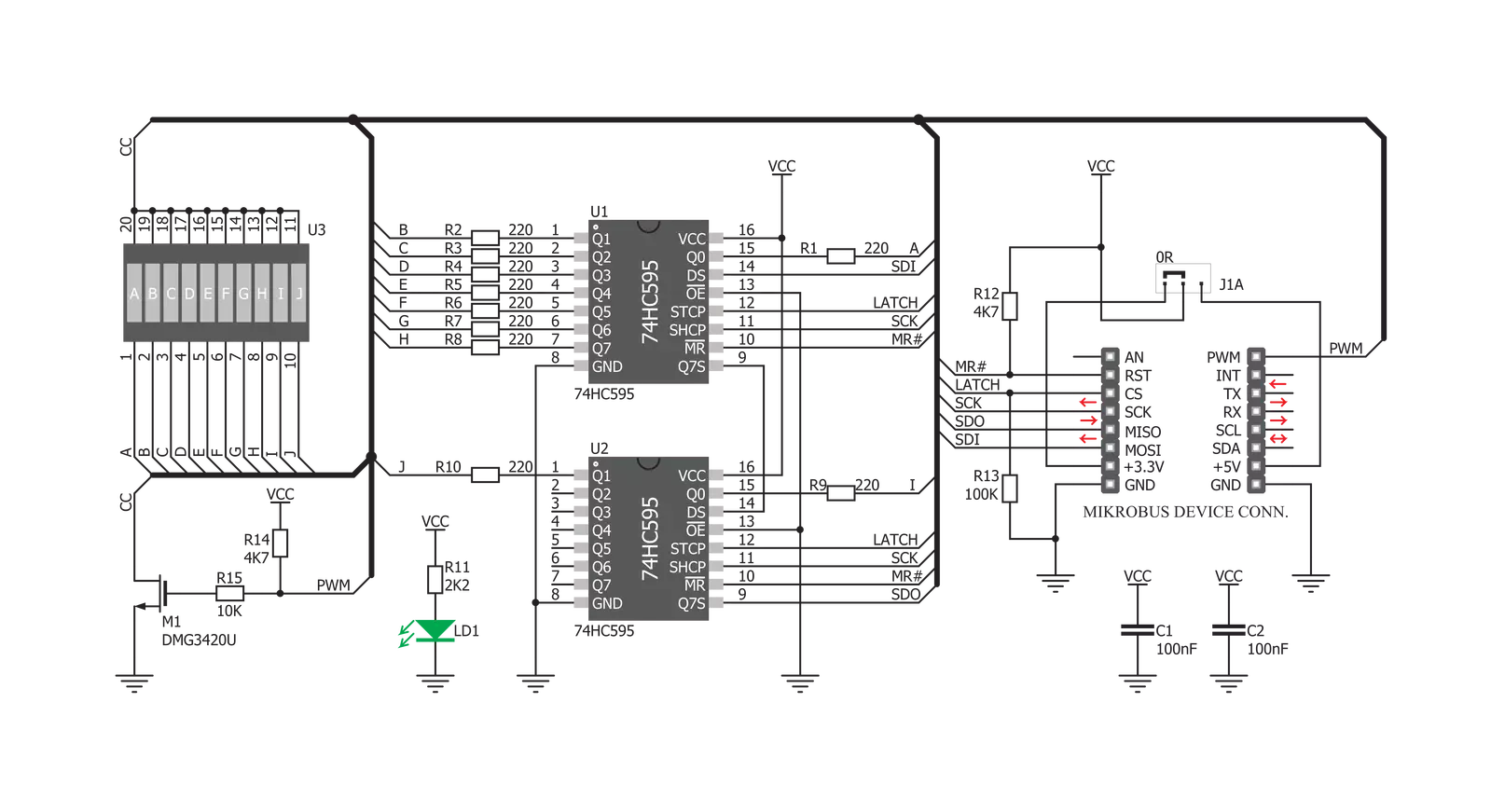

BarGraph Click is based on the JSB-R102510ZR, a bar graph LED array with ten red-colored LED segments from Ningbo, and two 74HC595, 8-bit serial-in, parallel-out shift registers with output latches from Texas Instruments to drive the JSB-R102510ZR. The 74HC595 ICs are comprised of a D-type internal storage register, as well as the serial-to-parallel shift register, both 8-bit wide. Each of these registers has its clock line, making it possible to clock in the desired data and then clock it out to the parallel output pins. The JSB-R102510ZR bar graph LED array has 10 red-colored LED segments. Each LED has its anode and cathode routed out, making each LED element absolutely independent so that it can be used in any circuit configuration. However, the JSB-R102510ZR bar graph display is connected as the display with the common cathode, meaning that all LED cathodes are connected to a single point. This LED cathode common line (CC) is connected to the drain of the N channel MOSFET, while its source is connected to the GND. Driving this MOSFET via its gate through the PWM pin of the mikroBUS™ allows dimming of the LED segments. Changing the PWM signal's duty cycle makes it possible to change the brightness of the XGURUGX10D bar graph display. The gate of this MOSFET is

connected to the PWM pin of the mikroBUS™ and it is pulled to VCC, allowing the display to work if the PWM pin is left floating. The Click board™ communicates with the host MCU via the mikroBUS™ SPI interface pins. Two bytes of information (16 bits in total) are pushed through the serial data input pin (DS) of the first 74HC595 IC, and routed to the SDI pin. The 74HC595 construction is such that after receiving 8 bits, clocking in one more bit will shift the existing 8 bits by one place, overflowing the last bit to the Q7S output pin and shifting it out that way. Since the Q7S of the first 74HC595 is connected to the DS pin of the second 74HC595, clocking 16 bits into the first 74HC595 IC will fill up both ICs with required data. Note that only two bits of the second byte will be used since the second shift register only has two outputs connected to the bar graph display (8 from the first IC + 2 from the second). It is worth mentioning that the Q7S of the last 74HC595 IC is routed to the MISO pin of the mikroBUS™, labeled as the SDO, allowing connection of multiple devices in cascade, building more complex setups. Adding more devices in the cascade would require more 8-bit words to be clocked into the first 74HC595 IC in the chain. When the data has been clocked in, the

SPI clock should be stopped, and the CS pin should be driven to a HIGH logic level. The CS pin of the mikroBUS™ is routed to the STCP pin of the 74HC595 ICs and labeled as LT on the Click board™. A rising edge on the STCP input pins of the 74HC595 ICs will latch the data from their internal storage registers to the output pins, polarizing the connected bar graph segment anodes. The onboard resistor pulls the STCP pin to a LOW logic level. If the previously mentioned MOSFET is in a conductive state, the current can flow through the LEDs, and the polarized LED elements will be lit. The #MR pin is used to clear the data in the internal storage register of the ICs. The LOW logic level on this pin will clear the content of this storage register, but it will not turn off the already activated outputs. The #MR pin is routed to the RST pin of the mikroBUS™, labeled as MR, and pulled to a HIGH logic level by the onboard resistor. This Click board™ can operate with either 3.3V or 5V logic voltage levels selected via the VCC SEL jumper. This way, both 3.3V and 5V capable MCUs can use the communication lines properly. Also, this Click board™ comes equipped with a library containing easy-to-use functions and an example code that can be used as a reference for further development.

Features overview

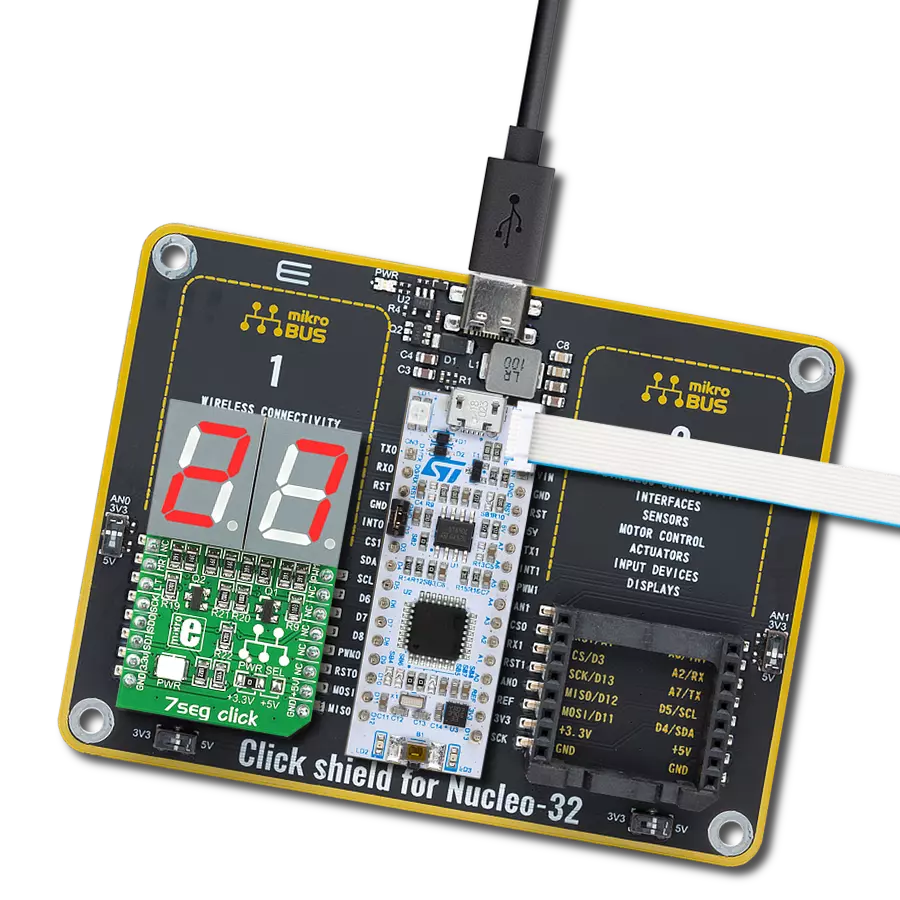

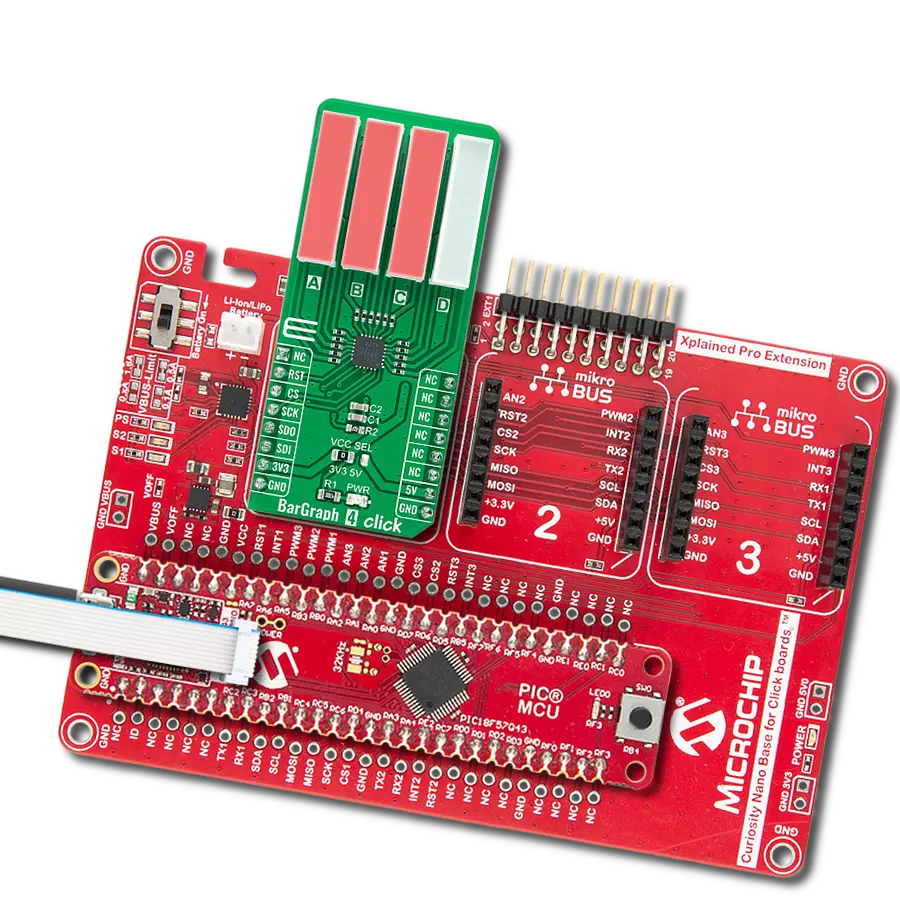

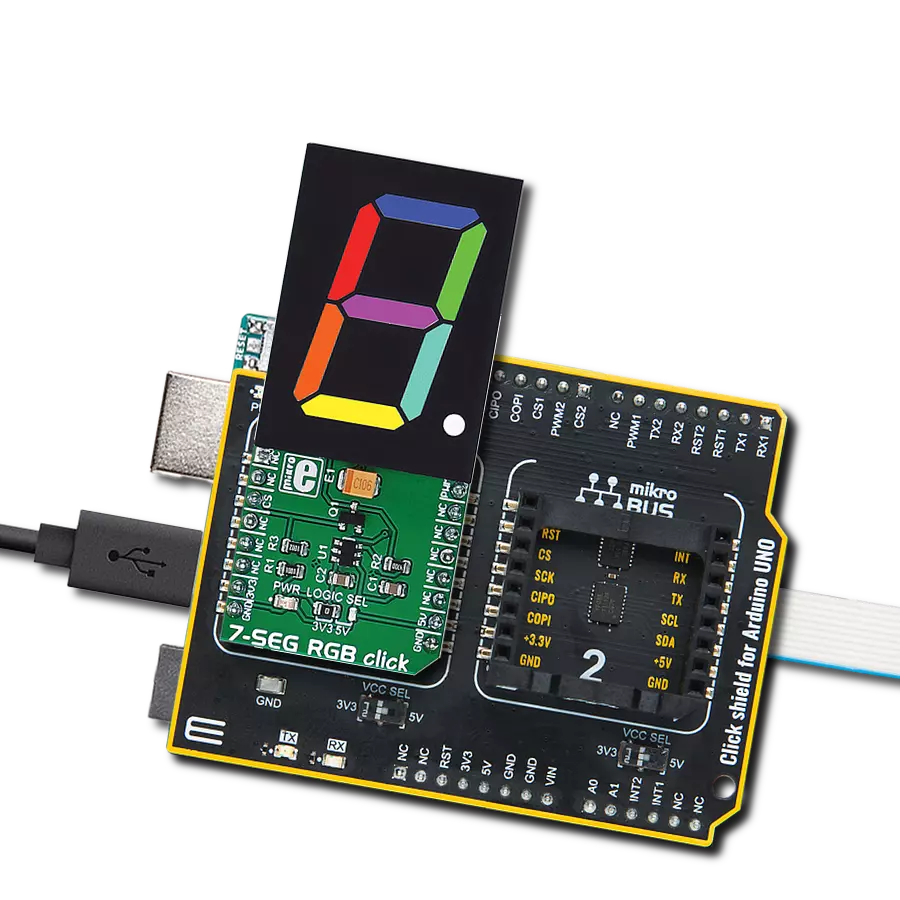

Development board

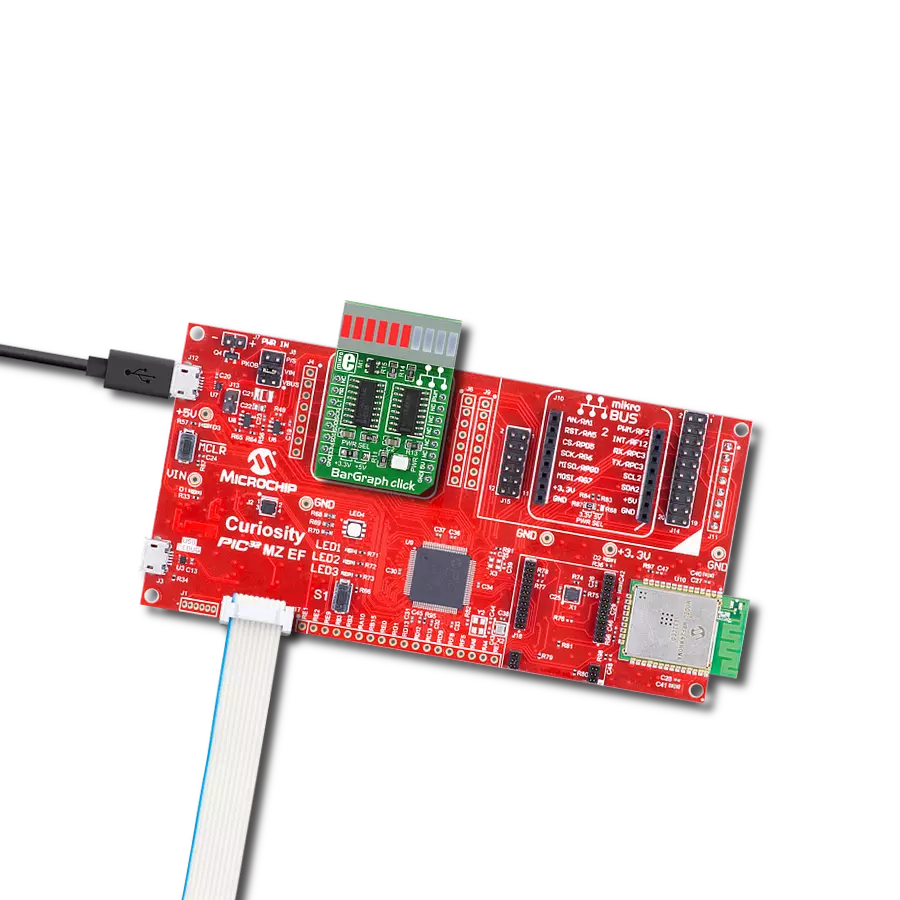

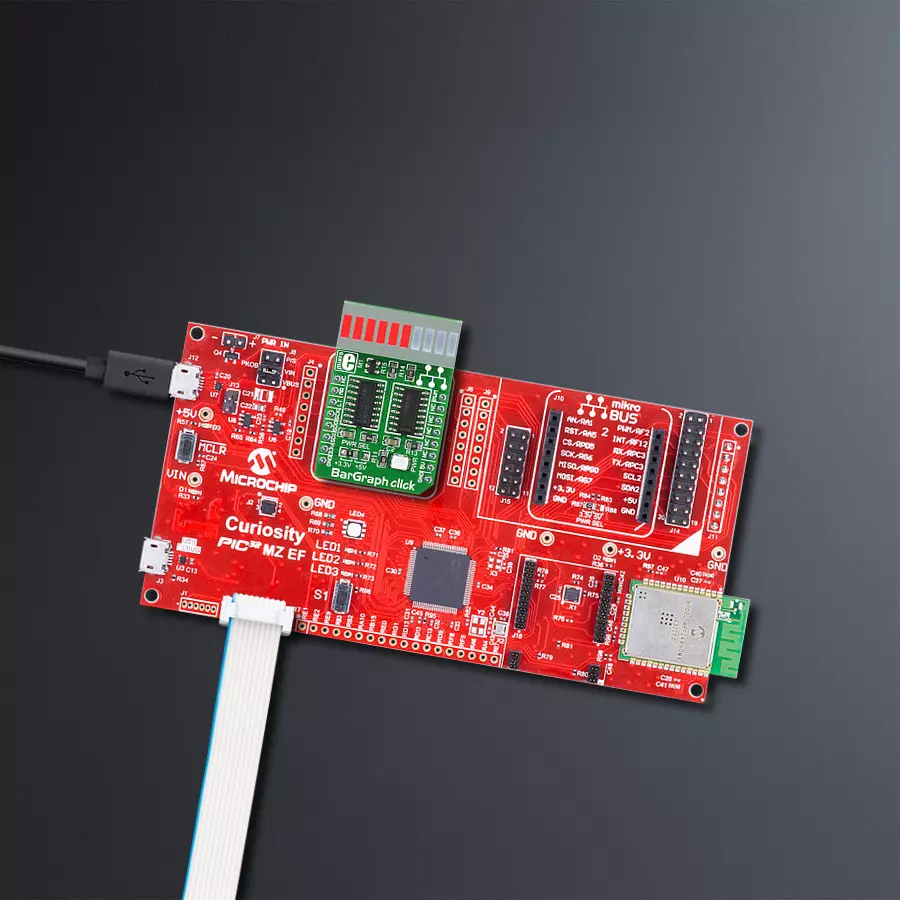

Curiosity PIC32 MZ EF development board is a fully integrated 32-bit development platform featuring the high-performance PIC32MZ EF Series (PIC32MZ2048EFM) that has a 2MB Flash, 512KB RAM, integrated FPU, Crypto accelerator, and excellent connectivity options. It includes an integrated programmer and debugger, requiring no additional hardware. Users can expand

functionality through MIKROE mikroBUS™ Click™ adapter boards, add Ethernet connectivity with the Microchip PHY daughter board, add WiFi connectivity capability using the Microchip expansions boards, and add audio input and output capability with Microchip audio daughter boards. These boards are fully integrated into PIC32’s powerful software framework, MPLAB Harmony,

which provides a flexible and modular interface to application development a rich set of inter-operable software stacks (TCP-IP, USB), and easy-to-use features. The Curiosity PIC32 MZ EF development board offers expansion capabilities making it an excellent choice for a rapid prototyping board in Connectivity, IOT, and general-purpose applications.

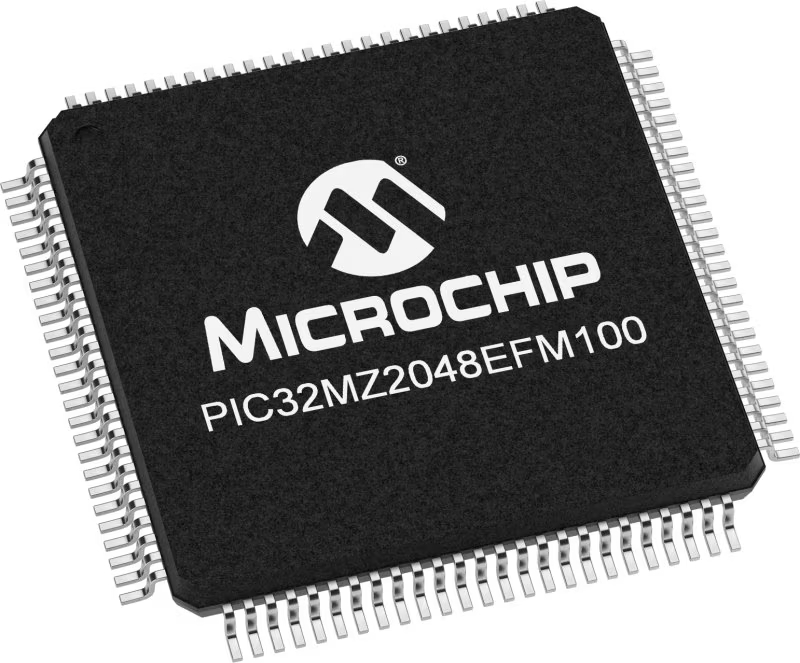

Microcontroller Overview

MCU Card / MCU

Architecture

PIC32

MCU Memory (KB)

2048

Silicon Vendor

Microchip

Pin count

100

RAM (Bytes)

524288

Used MCU Pins

mikroBUS™ mapper

Take a closer look

Click board™ Schematic

Step by step

Project assembly

Software Support

Library Description

This library contains API for BarGraph Click driver.

Key functions:

bargraph_driver_init- Functions for initializes the chipbargraph_reset- Functions for reset the chipbargraph_display- Displays function.

Open Source

Code example

The complete application code and a ready-to-use project are available through the NECTO Studio Package Manager for direct installation in the NECTO Studio. The application code can also be found on the MIKROE GitHub account.

/*!

* \file

* \brief BarGraph Click example

*

* # Description

* This application uses a high-quality bar graph LED display.

*

* The demo application is composed of two sections :

*

* ## Application Init

* Initializes driver init and BarGraph init.

*

* ## Application Task

* Counter passes through the loop and logs the value of the counter on the bargraph display.

*

* \author MikroE Team

*

*/

// ------------------------------------------------------------------- INCLUDES

#include "board.h"

#include "log.h"

#include "bargraph.h"

// ------------------------------------------------------------------ VARIABLES

static bargraph_t bargraph;

static log_t logger;

// ------------------------------------------------------ APPLICATION FUNCTIONS

void application_init ( void )

{

log_cfg_t log_cfg;

bargraph_cfg_t cfg;

/**

* Logger initialization.

* Default baud rate: 115200

* Default log level: LOG_LEVEL_DEBUG

* @note If USB_UART_RX and USB_UART_TX

* are defined as HAL_PIN_NC, you will

* need to define them manually for log to work.

* See @b LOG_MAP_USB_UART macro definition for detailed explanation.

*/

LOG_MAP_USB_UART( log_cfg );

log_init( &logger, &log_cfg );

log_info( &logger, "---- Application Init ----" );

// Click initialization.

bargraph_cfg_setup( &cfg );

BARGRAPH_MAP_MIKROBUS( cfg, MIKROBUS_1 );

bargraph_init( &bargraph, &cfg );

bargraph_reset( &bargraph );

}

void application_task ( void )

{

uint8_t cnt = 0;

for ( cnt = 0; cnt <= 10; cnt++ )

{

bargraph_display( &bargraph, cnt );

Delay_ms ( 500 );

}

}

int main ( void )

{

/* Do not remove this line or clock might not be set correctly. */

#ifdef PREINIT_SUPPORTED

preinit();

#endif

application_init( );

for ( ; ; )

{

application_task( );

}

return 0;

}

// ------------------------------------------------------------------------ END

Additional Support

Resources

Category:LED Segment