Measuring heat with ease has never been simpler, thanks to our innovative temperature monitoring solution.

A

A

Hardware Overview

How does it work?

Thermo 20 Click is based on the TSYS03, an ultra-compact digital temperature sensor with precise digital output and low power consumption from TE Connectivity. The TSYS03 is factory-calibrated and provides accurate temperature measurements through several I2C configurable addresses. Operating from a supply voltage between 2.4V and 5.5V and drawing just 5µA Thermo 20 Click board™ is well suited for battery-powered and automotive applications. With an extended operating range from -40°C to +125°C, the TSYS03 provides digital temperature measurements that offer an accuracy of ±0.5°C when operating at ambient temperatures between 0°C and 60°C. The TSYS03 consists of a semiconductor

diode as a measuring element, which was integrated into an ASIC. The temperature is obtained from the voltage that drops across the diode and through an A/D converter with a 16-bit resolution. The output is obtained as a digital value via a configurable I2C interface. The TSYS03 impresses with its high accuracy, current consumption lower than 5 µA, and low self-heating of max. 0.1 °C. Thermo 20 Click communicates with MCU using the standard I2C 2-Wire interface with a maximum clock frequency of 1MHz. The standard I2C address is 0x40, but the sensor can also react to a second, alternative I2C address. It is possible to do one-time subsequent writing of an alternative static I2C address.

This leads to a wrong memory CRC, but the sensor is still functional. It is also possible to write an alternative I2C address to the sensor during operation. This address is temporary and is overwritten during a software reset or a hardware restart function. This Click board™ can operate with either 3.3V or 5V logic voltage levels selected via the VCC SEL jumper. This way, both 3.3V and 5V capable MCUs can use the communication lines properly. Also, this Click board™ comes equipped with a library containing easy-to-use functions and an example code that can be used as a reference for further development.

Features overview

Development board

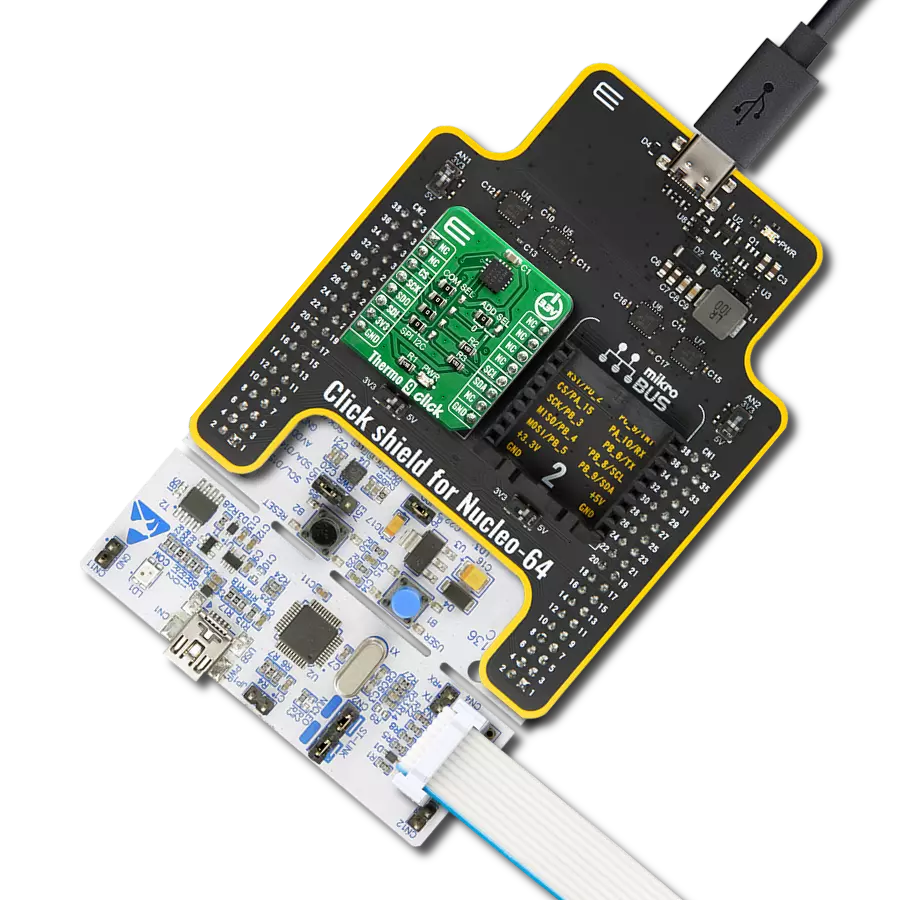

Nucleo 32 with STM32F031K6 MCU board provides an affordable and flexible platform for experimenting with STM32 microcontrollers in 32-pin packages. Featuring Arduino™ Nano connectivity, it allows easy expansion with specialized shields, while being mbed-enabled for seamless integration with online resources. The

board includes an on-board ST-LINK/V2-1 debugger/programmer, supporting USB reenumeration with three interfaces: Virtual Com port, mass storage, and debug port. It offers a flexible power supply through either USB VBUS or an external source. Additionally, it includes three LEDs (LD1 for USB communication, LD2 for power,

and LD3 as a user LED) and a reset push button. The STM32 Nucleo-32 board is supported by various Integrated Development Environments (IDEs) such as IAR™, Keil®, and GCC-based IDEs like AC6 SW4STM32, making it a versatile tool for developers.

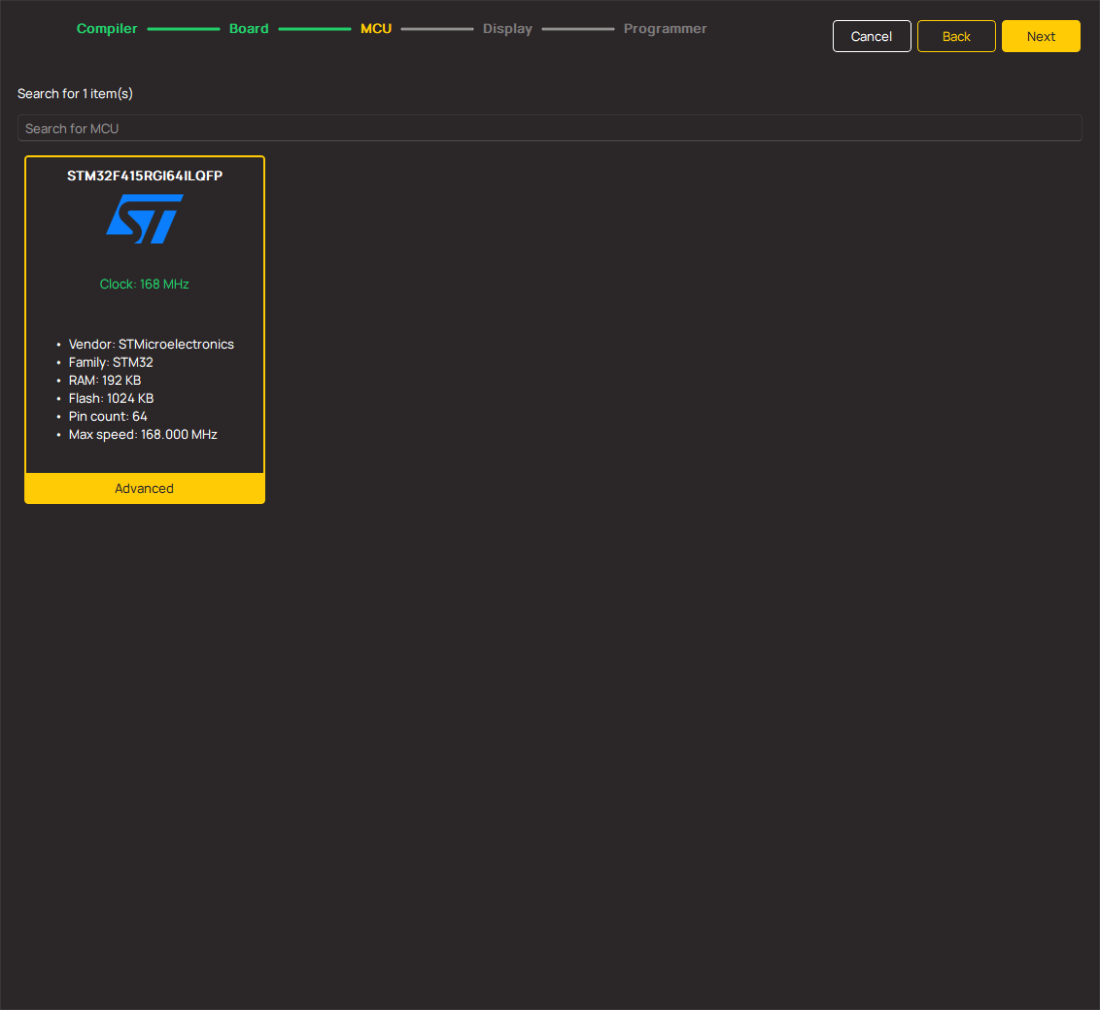

Microcontroller Overview

MCU Card / MCU

Architecture

ARM Cortex-M0

MCU Memory (KB)

32

Silicon Vendor

STMicroelectronics

Pin count

32

RAM (Bytes)

4096

You complete me!

Accessories

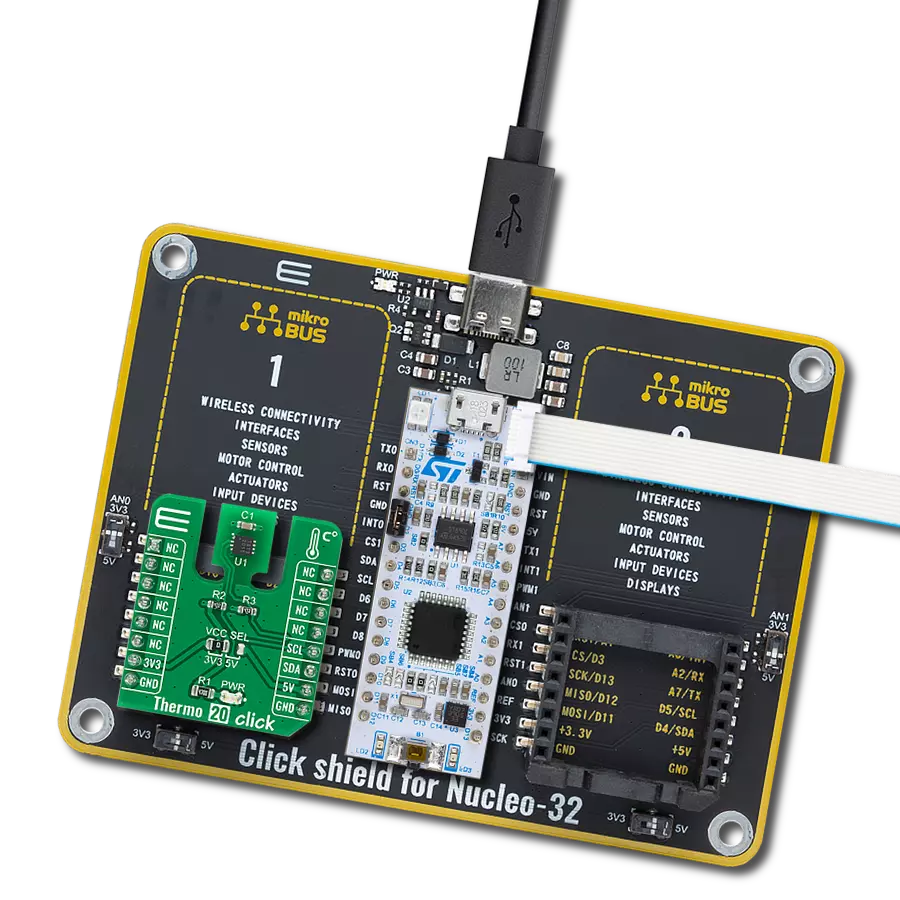

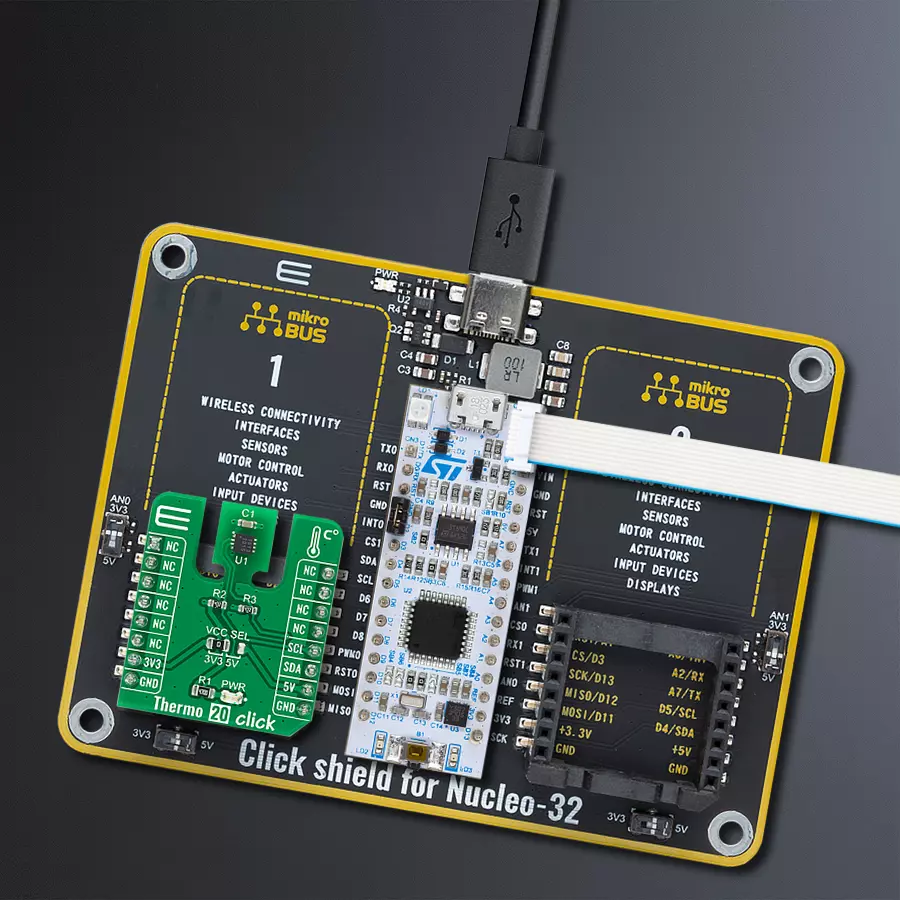

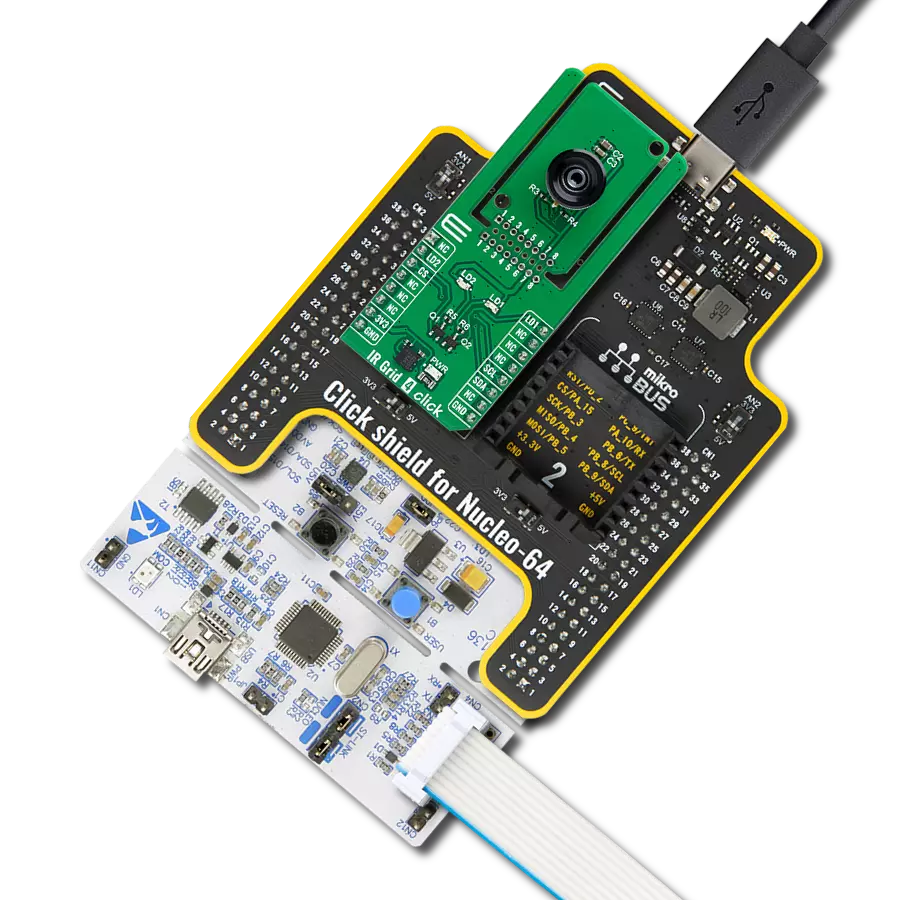

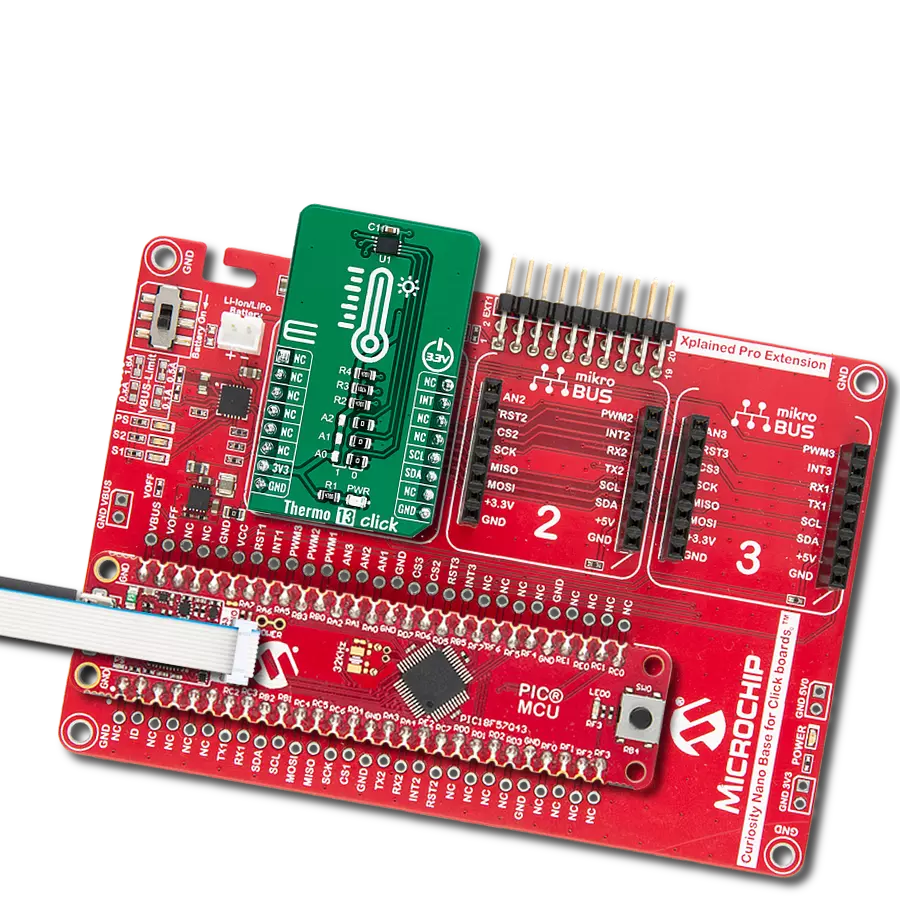

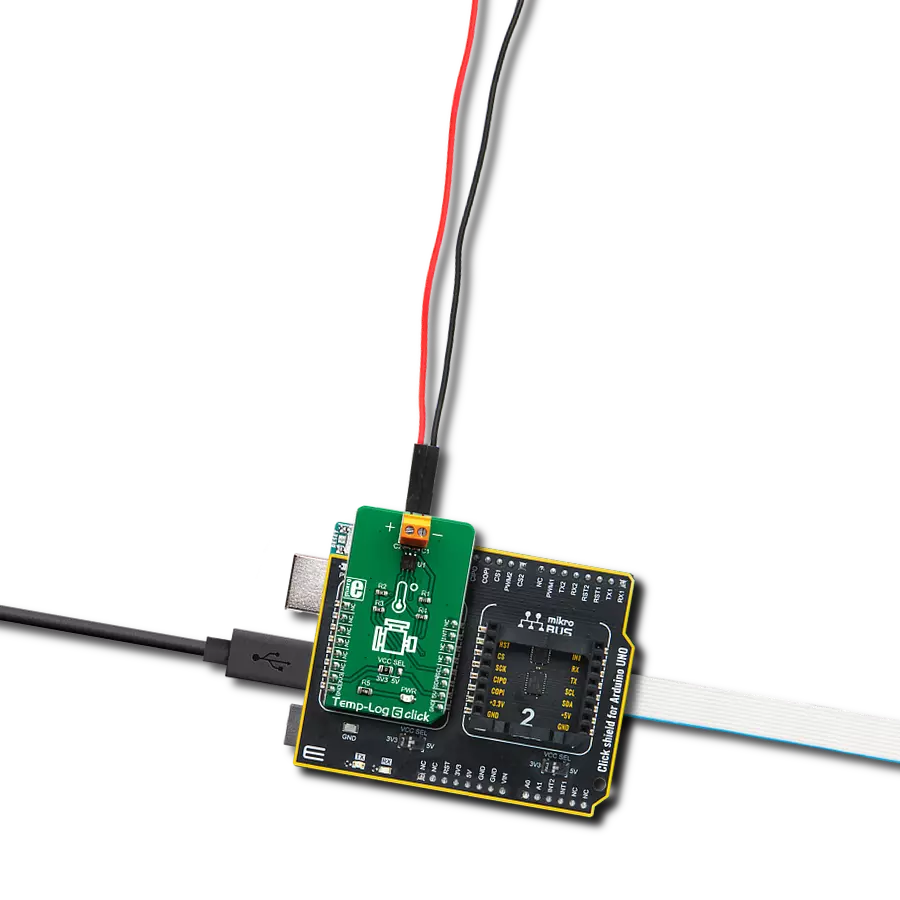

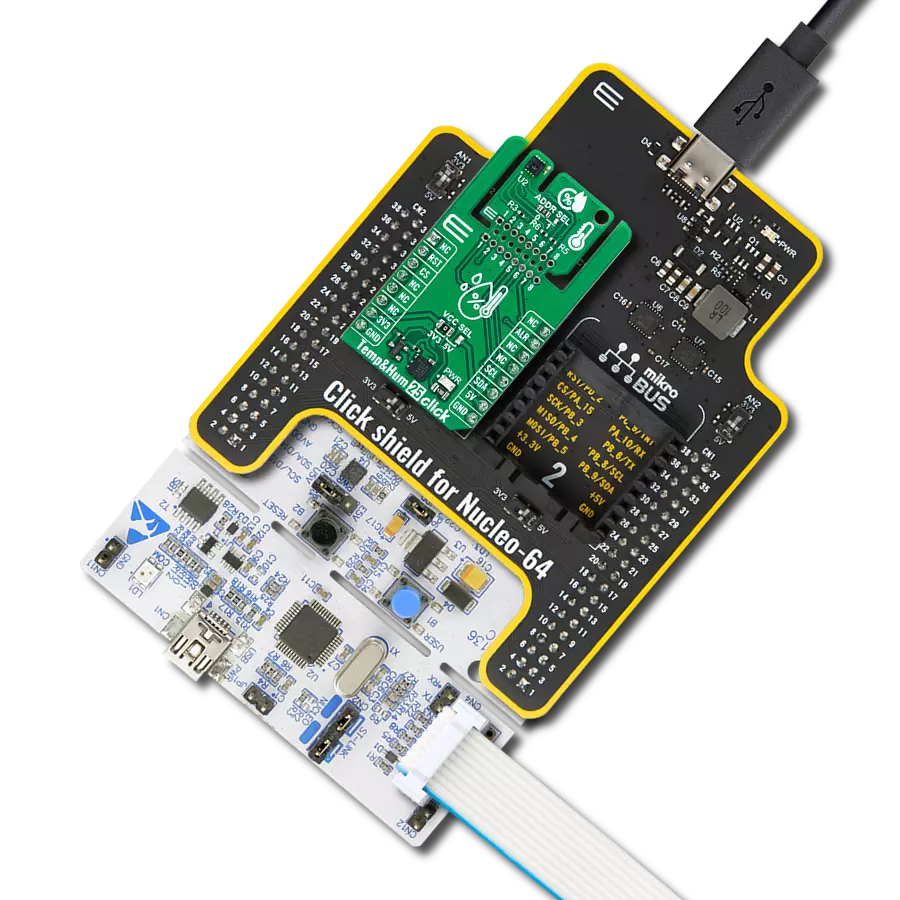

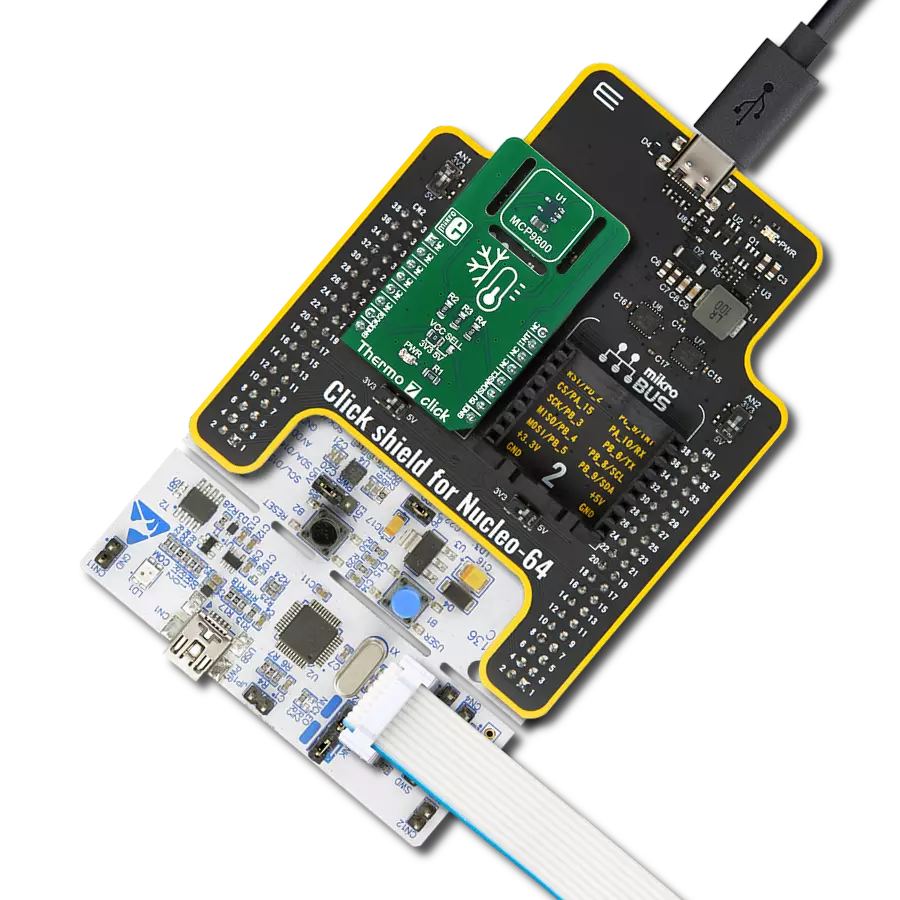

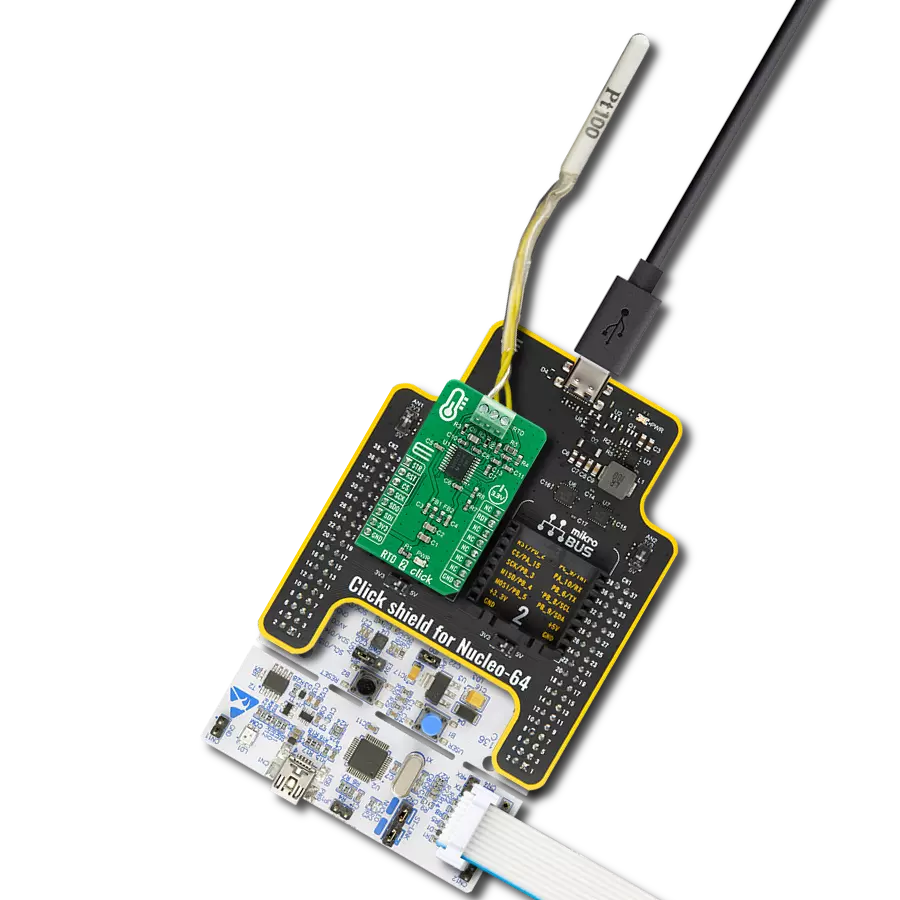

Click Shield for Nucleo-32 is the perfect way to expand your development board's functionalities with STM32 Nucleo-32 pinout. The Click Shield for Nucleo-32 provides two mikroBUS™ sockets to add any functionality from our ever-growing range of Click boards™. We are fully stocked with everything, from sensors and WiFi transceivers to motor control and audio amplifiers. The Click Shield for Nucleo-32 is compatible with the STM32 Nucleo-32 board, providing an affordable and flexible way for users to try out new ideas and quickly create prototypes with any STM32 microcontrollers, choosing from the various combinations of performance, power consumption, and features. The STM32 Nucleo-32 boards do not require any separate probe as they integrate the ST-LINK/V2-1 debugger/programmer and come with the STM32 comprehensive software HAL library and various packaged software examples. This development platform provides users with an effortless and common way to combine the STM32 Nucleo-32 footprint compatible board with their favorite Click boards™ in their upcoming projects.

Used MCU Pins

mikroBUS™ mapper

Take a closer look

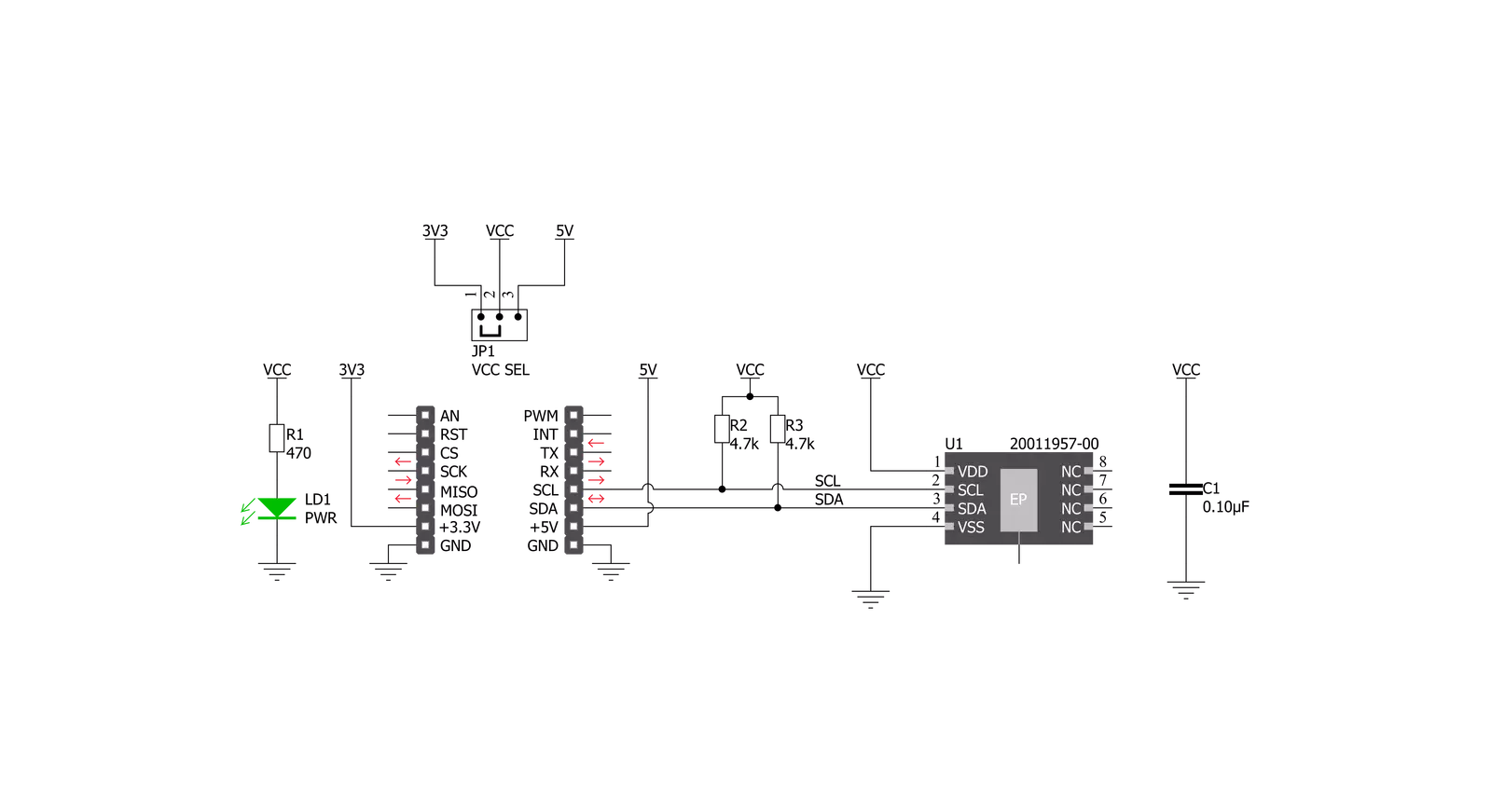

Click board™ Schematic

Step by step

Project assembly

Software Support

Library Description

This library contains API for Thermo 20 Click driver.

Key functions:

thermo20_set_cmd- Send command function.thermo20_start_conversion- Start conversion function.thermo20_get_temperature- Get temperature data function.

Open Source

Code example

The complete application code and a ready-to-use project are available through the NECTO Studio Package Manager for direct installation in the NECTO Studio. The application code can also be found on the MIKROE GitHub account.

/*!

* @file main.c

* @brief Thermo20 Click example

*

* # Description

* This example showcases the ability of Thermo 20 Click board to

* read it's serial number. It can read themperature and measure from -40degC to

* 120degC.

*

* The demo application is composed of two sections :

*

* ## Application Init

* Initialization communication modules(I2C, UART). Resets device and read Serial Number.

*

* ## Application Task

* In span of ~ 1000ms it sends command for adc conversion of temperature, reads ADC value,

* and calculates temperature in degrees C.

*

* @note For this driver to work on 18bit PIC MCU-s you need to additionally pull up communication lines.

*

* @author Mikroe Team

*

*/

#include "board.h"

#include "log.h"

#include "thermo20.h"

static thermo20_t thermo20;

static log_t logger;

void application_init ( void )

{

log_cfg_t log_cfg; /**< Logger config object. */

thermo20_cfg_t thermo20_cfg; /**< Click config object. */

/**

* Logger initialization.

* Default baud rate: 115200

* Default log level: LOG_LEVEL_DEBUG

* @note If USB_UART_RX and USB_UART_TX

* are defined as HAL_PIN_NC, you will

* need to define them manually for log to work.

* See @b LOG_MAP_USB_UART macro definition for detailed explanation.

*/

LOG_MAP_USB_UART( log_cfg );

log_init( &logger, &log_cfg );

log_info( &logger, " Application Init " );

// Click initialization.

thermo20_cfg_setup( &thermo20_cfg );

THERMO20_MAP_MIKROBUS( thermo20_cfg, MIKROBUS_1 );

err_t init_flag = thermo20_init( &thermo20, &thermo20_cfg );

if ( I2C_MASTER_ERROR == init_flag )

{

log_error( &logger, " Application Init Error. " );

log_info( &logger, " Please, run program again... " );

for ( ; ; );

}

thermo20_default_cfg ( &thermo20 );

uint32_t ser_numb = thermo20_get_serial_number( &thermo20 );

log_printf( &logger, " > Serial Number: %lu\r\n", ser_numb );

log_info( &logger, " Application Task " );

}

void application_task ( void )

{

thermo20_start_conversion( &thermo20 );

float temperature = thermo20_get_temperature( &thermo20 );

log_printf( &logger, " > Temperature[deg C]: %.2f\r\n", temperature );

Delay_ms ( 1000 );

}

int main ( void )

{

/* Do not remove this line or clock might not be set correctly. */

#ifdef PREINIT_SUPPORTED

preinit();

#endif

application_init( );

for ( ; ; )

{

application_task( );

}

return 0;

}

// ------------------------------------------------------------------------ END

Additional Support

Resources

Category:Temperature & humidity